A substation, that cornerstone of the electricity system, often a mini, quirky corner building in any local area, is essential to grid reliability: converting voltage for local use, distributing energy and controlling power flows to and (now) from businesses and homes in its vicinity. Digital substations are not a new concept, but incorporating smarts into their performance, responsiveness and resilience is becoming key to managing rooftop PV resources, grid-connected and off-grid industrial energy supplies, and large-scale renewable generation.

This year, Hitachi ABB launched its Smart Digital Substation, which combines digital technology with the company’s Lumada Asset Performance Management (APM) software solution, to provide money-saving predictive management of substation assets. Its data interpretation also facilitates grid planning as more variable renewable assets, energy storage and loads/households are added to any sector of the grid.

A recent global report by Spanish software company, RatedPower, adds fuel to the expectation that digitalisation is set to transform the energy supply chain to favour renewable generation.

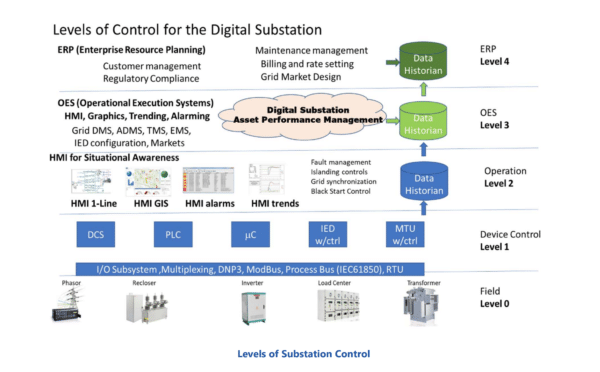

The digital substation is not bound up in physical bundles of copper wire, but orchestrates networks of intelligent electrical devices (IEDs) that monitor and direct electricity flow to maintain balance in the grid.

“Upgrading to a smart digital substation makes all the information generated by those networks accessible to grid operators,” Hitachi ABB’s Claus Vetter, told pv magazine Australia.

Speaking from Hitachi-ABB Power Grid’s headquarters in Switzerland, where he is Global Product Manager for the Automation and Communication division, Vetter explained that the reduction in cabling of a digital substation not only substantially reduces the real estate it occupies, but simplifies the connection of any generator or load to the system — “obviously giving a great advantage in terms of the speed at which we can integrate renewables into the grid”.

The smaller footprint of digital substations also facilitates placement and control of renewable resources and storage devices as they’re added to neighbourhoods, incorporated in smart cities and built to power industrial sites.

Vetter gives Deutsche Bahn, Germany’s railway operator, a massive electricity user that runs its own power infrastructure, and Australian mines, as examples of operations to which energy is critical. He says both these kinds of energy users/producers will increasingly seek to ensure reliability is maintained in a renewably powered world, and as such form part of the market for smart digital substations.

Data generated by sensors and devices within the digital substation, showing the responses of equipment to variable renewable energy flows and congestion at times of peak solar generation, for instance, can help utilities and high-energy industrial sites better manage performance of their assets, and also predictively choose when to conduct maintenance that requires downtime.

Hitachi ABB Power Grids modelling shows that its Smart Digital Substation can save utilities millions of dollars otherwise lost due to asset failure in extreme weather events, by determining effective ways of rerouting resources; and by reducing unplanned outages.

The key to continuously and reliably balancing the grid lies in precisely understanding the impacts of everyday weather and cloud cover on renewable energy flows, and being able to forecast load — time of use — with greater fidelity, says Bryan Friehauf, Senior Vice President of Enterprise Software Solutions at ABB Hitachi Power Grids.

Smart digital substations are the aggregators of such data at a local level, and can ultimately communicate with one another — as smart digital infrastructure becomes more ubiquitous — to coordinate responses on a larger scale.

Vetter adds that data flowing from smart digital substations can also help utilities remotely manage responses to irregularities or failures in substation systems, reducing the number of site visits required for diagnostics and repair, and thereby reducing the carbon emissions generated by driving today’s internal-combustion-engine service vehicles to site.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.