The expansion follows a successful trial last year in which the company boosted the capacity of lithium-ion coin cells by 30%.

The company is now looking to prove its technology can be integrated with more powerful batteries, with its eyes ultimately on the European electric vehicle market.

Image: Altech

Cracking the ‘silicon barrier’

In 2021, Altech produced and tested a series of lithium-ion battery anode materials which had a ~30% higher retention capacity compared to conventional lithium-ion battery anode materials. To achieve this, the combined silicon particles that had been treated with its proprietary coating technology, with regular battery grade graphite, to produce a lithium-ion battery electrode containing a composite graphite / silicon anode. When energised, these materials held 30% more capacity compared to a conventional graphite only anode material, the company said, adding the batteries also had increased cyclability.

The battery performance testing was conducted with only the industry standard coin cell rechargeable lithium-ion batteries though – which the company noted has its limitations.

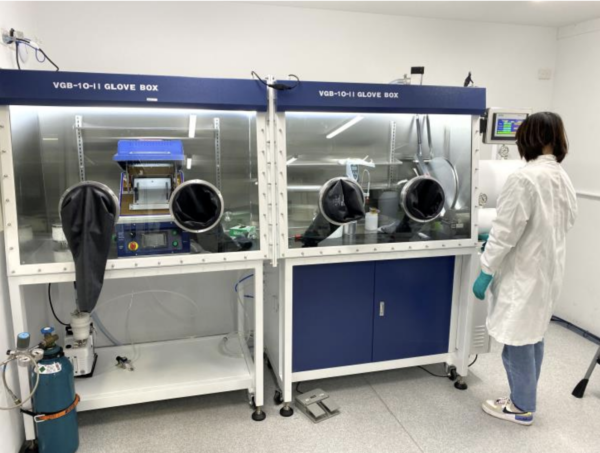

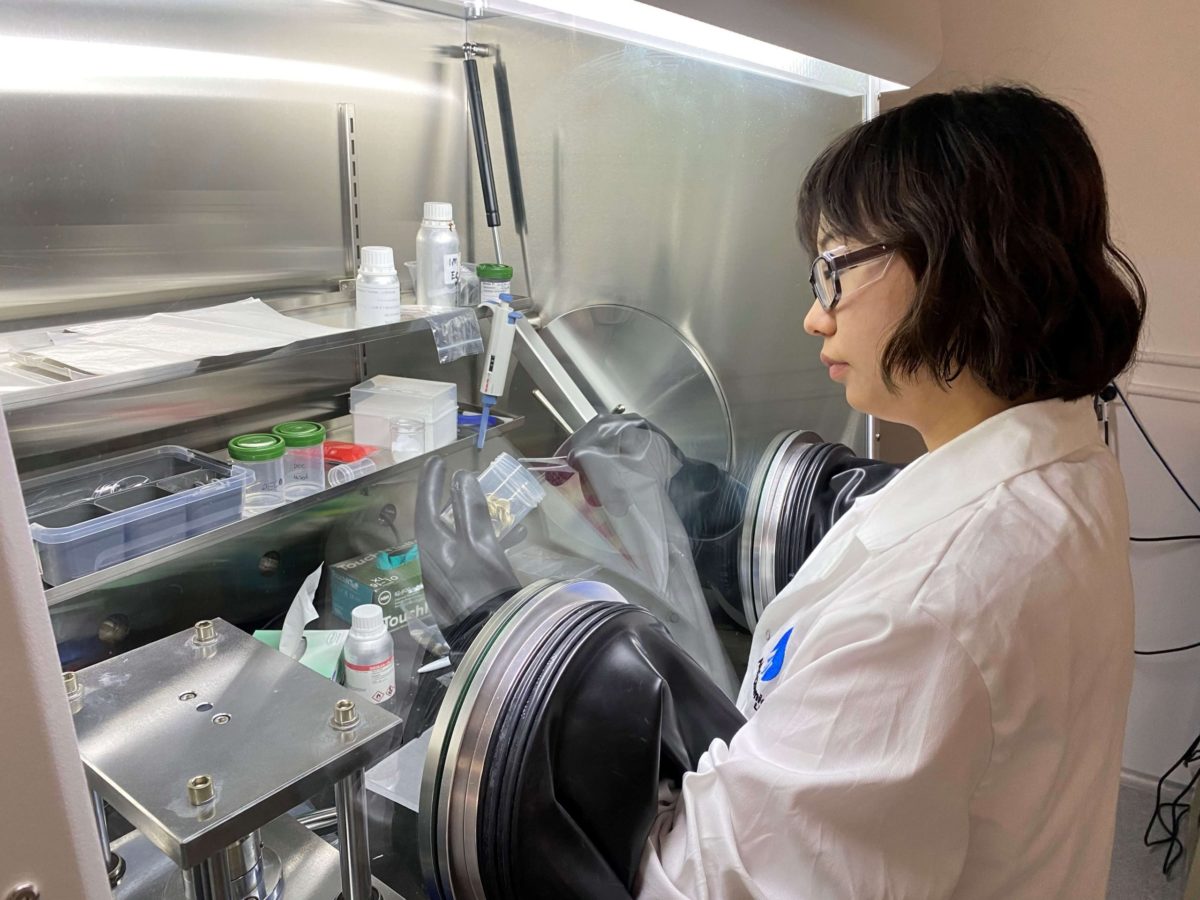

Since that trial, Altech has fitted its Perth laboratories with a pouch cell production and testing facility. (A pouch cell is a common design of a lithium-ion battery.)

It has also commissioned a larger-scale tube furnace at the lab. It is hoping these expanded facilities will help it prove its trademarked Silumina Anodes technology.

Projects in Germany & Malaysia

Alongside its Perth R&D, the ASX-listed company is progressing plans to develop a high purity alumina (HPA) battery material coating plant in Germany. To that end, Altech’s 75%-owned subsidiary, Altech Industries Germany, has commenced a definitive feasibility study for the development of a 10,000 tonne per annum silicon/graphite alumina coating plant in Saxony.

The company is also pursuing a project in Malaysia, aiming to build a 4,500 tonne per annum high purity alumina (HPA) processing plant at Johor. Feedstock for the plant will be sourced from Altech’s kaolin deposit at Meckering, in WA, and shipped to Malaysia.

Altech has already released a Final Investment Decision Study for the Malaysian project, and has secured a US$190 million (AU$275m) loan with German owned state bank KfW IPEX-Bank. It continues to negotiate US$100m of Green Corporate Bonds, as well as US$100m equity stake in this project, in order to finalise construction.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.