From pv magazine ISSUE 10 – 2022

While your work on crystalline silicon technology has had a profound impact on the modern solar industry, you are now working on thin films, and we’re not talking about commercialised products such as CIGS, CdTe or even a-Si. Can you tell us more about your work in this field and the progress you’re making?

We would really like to find something that has all of the good properties of silicon but a different bandgap. We’re looking at synthesising thin films of different combinations of elements from the periodic table. We’re looking at ternaries or quaternaries now and we’re working through the periodic table to see what we can find.

The real challenge has been getting the efficiency to the required level. I think you need 20% to have a solar cell that is worth stacking onto silicon. Although, some of these technologies might have a life of their own for things like building-integrated PV or other applications where efficiency wouldn’t be all that critical.

We have seen with perovskites that once a photovoltaic material is discovered, its efficiency increase can be very rapid. Is that the aim?

That is what we are hoping for. But perovskites are quite unique in that they have been a technology where it has been relatively easy to increase efficiency. That has been one of the strengths of the technology. The reason for it might be linked to one of the weaknesses of the technology: the fact that it is so forgiving of defects might be related to why it is so unstable as well. With some of the other materials we are working on, materials we are finding it difficult to increase the efficiency of, they might win out – in terms of stability – if we can get the efficiency up there.

What are some of the promising candidates?

We hold the world record at the UNSW for CZTS – the pure sulfide version. That seems to have all of the attributes that we are after; the constituents are all benign elements and all pretty abundant so it’s the closest thing to artificial silicon that you can make. But getting the efficiency up to 20% is proving difficult, we’re presently at around 12%.

If you look back at the history of CIGS, the 1980s was a dead era for CIGS and the efficiency didn’t really start to increase until the 1990s – it was the discovery that sodium made the difference which really pushed the efficiency along. We are looking at the sodium needed for the CZTS, which may be the ingredient that turns it from being very hard work to a winning technology.

The other advantage of CZTS over some perovskites is that there is no lead – is that right?

The amount of lead in perovskite is very small and people say ‘if it all dropped out onto the ground the level would still be tolerable anyway.’ But I think it would be better if we had PV technology that was completely benign and recyclable and fully environmentally sound. Why settle for second best?

The WCPEC prize reflects your long and illustrious career in PV research. It is widely thought that the PERC cell architecture has had a profound impact and enabled the PV industry to scale. Your team has done some research on this impact – what did you find?

The WCPEC prize reflects your long and illustrious career in PV research. It is widely thought that the PERC cell architecture has had a profound impact and enabled the PV industry to scale. Your team has done some research on this impact – what did you find?

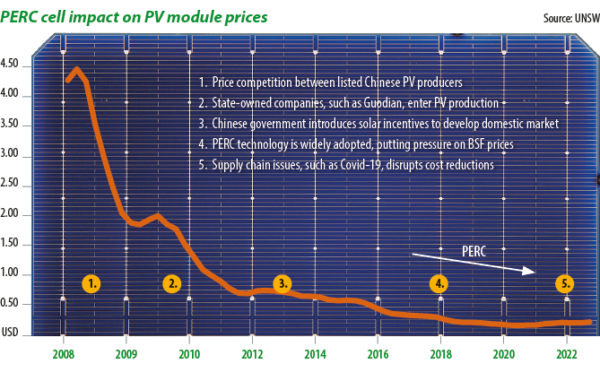

If you look at the published average selling prices, from the likes of PVInsight and InfoLink, you can see there is a definite break. Between 2008 and 2012 there were massive cost declines as cashed-up Chinese companies – a result of their public listings – competed with each other in an attempt to gain market share. But from 2012 to 2016 there was a fairly steady decline of about 12% per year in PV average selling prices. Then, all of a sudden, around 2016, there is a clear break point where the annual price fall accelerated to 22% for the multicrystalline panels. That is the very point in time when PERC started picking up the pace, big time.

My take is that the pressure PERC was putting on the multicrystalline manufacturers forced them to drop prices in an attempt to maintain their market share, so PERC was the thing that accelerated their cost reduction. Until mid 2020, when the coronavirus and other issues destroyed the steady cost reductions that had been achieved since 2016, it was a pretty steady 22% rate that the technology was reducing in price.

So we credit PERC in that transition and if you extrapolate from 2016 to the end of 2020 at 12% a year or 22% a year, then you get PERC, with the accelerated cost reduction, to an average selling price of 54% of what it would’ve been at a business-as-usual scenario. We consequently claim that PERC has accelerated the cost of reduction to nearly double what it would’ve been without PERC having been introduced.

And that presumably translates into PV system prices, is that right?

I have made a point of compiling the lowest bids for power purchase agreements since 2014 and we can see a very rapid transition around 2016. That is when developers are bidding a few years in advance of when they have to supply the technology, and they were all bidding on bifacial PERC, around then, causing a dramatic cost reduction. I think that PERC has had a really big impact on these bids.

I also think PERC accelerated innovation in modules, because cells could be made bifacial at low cost and that meant you had to pattern the back of the cell. That, in turn, made the cells easier to cut in half encouraging the move to bigger wafers and so on. So, I think the impact was much more than people realise, both in terms of costs and the ways in which the technology evolved to bigger wafers and modules, and all of that PERC can take credit for.

Very humbly of course…

[Laughs] Yes, we very humbly take credit for it.On a personal note, what are your goals before you decide to wind up your career as a solar researcher?

The next decade is going to be the most exciting decade for photovoltaics. We are going to see PV displace coal for electricity production and things are going to happen much more quickly than most people think. We are going to see a transformation of the energy industry over that period and Australia is going to lead the way. That makes it even more exciting for us.

And you’re determined, personally, to be a part of it?

I would really like to crack this tandem technology; finding something that you can stack on silicon that is stable and efficient would be ideal. I hope to nail that before I can retire. I’m quite keen to get that done but it is proving quite difficult.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.