Sparc Hydrogen, a joint venture between Sparc Technologies (52%), Fortescue (20%), and the University of Adelaide (28%), has completed the first demonstration and testing of its prototype photocatalytic water splitting reactor outside the laboratory, using the CSIRO facility in Newcastle, New South Wales. The company is seeking to develop what it hopes will be “next generation green hydrogen technology.”

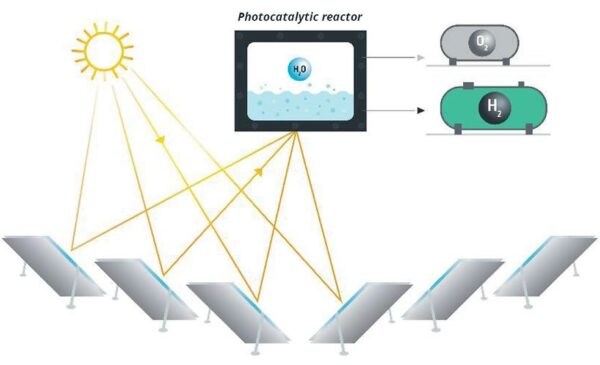

An alternative to making green hydrogen via electrolysis, photocatalytic water splitting instead relies directly on sunlight, water and a photocatalyst. Sparc Hydrogen is developing a photocatalytic reactor, patent pending, which seeks to efficiently take hydrogen from water molecules using concentrated solar.

Image: Sparc Technologies

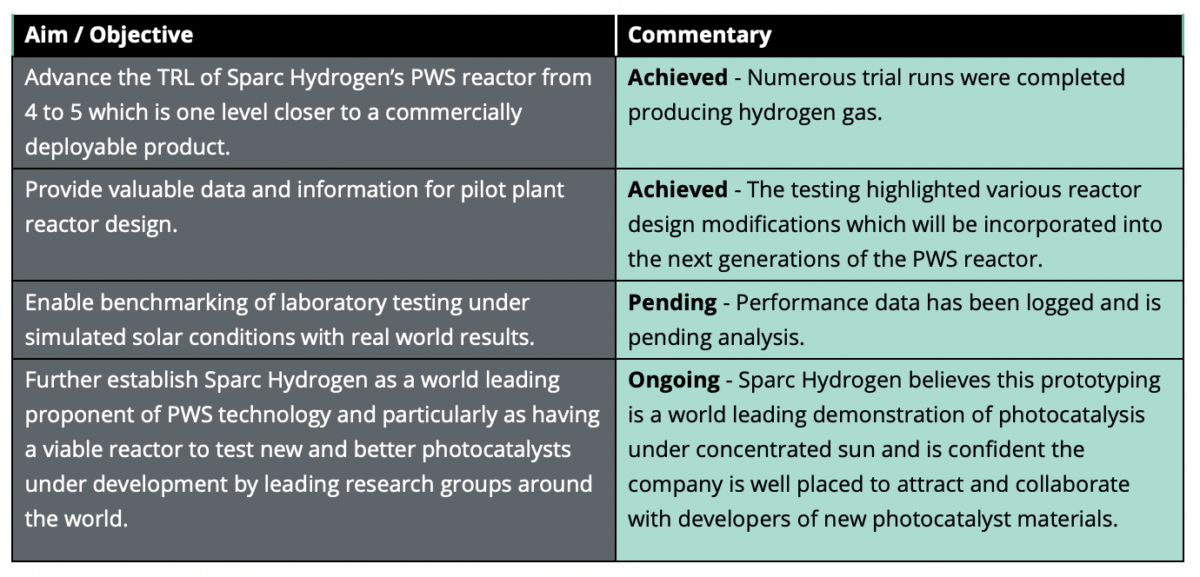

Australian government science agency, the CSIRO, has been operating a concentrated solar thermal plant known as the CSIRO Energy Centre in Newcastle, where Sparc Hydrogen recently completed its initial testing. “The data and learnings from the repeated on-sun trials are invaluable and will improve reactor design as we continue to scale the technology towards a pilot plant,” Sparc Technologies Executive Chair, Stephen Hunt, said.

Alongside the prototype testing, the company announced it had been working with an unnamed external consultant to complete a pilot plant pre-FEED (Preliminary-Front End Engineering and Design) study.

It said that study will completed before the year is out and is based on a site location “proximal to Adelaide.” It will incorporate a concept flowsheet design, equipment selection, costs, risks and opportunities for a pilot plant which will enable continuous on-sun testing of the technology, the company said, noting the plant’s commissioning would be the next stage in its technology’s readiness.

Image: Sparc Hydrogen

“The study will provide valuable information for grant applications and will form the basis for detailed design and engineering in 2024,” Sparc Hydrogen said, with its Annual General Meeting notice saying this was expected in the first half of the year.

Sparc Hydrogen believes photocatalytic water splitting can deliver cost and flexibility advantages over electrolysis because of its lowered infrastructure and electricity requirements. The company has been awarded almost $500,000 (USD 315,000) by the Australian government to support the development of its photocatalytic technology

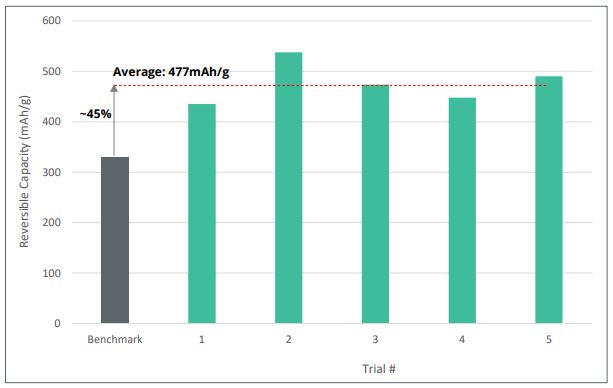

Sparc Technologies, the majority stakeholder in Sparc Hydrogen, is developing two other product streams: sodium-ion battery technology, which it is pursuing in partnership with Queensland University of Technology (QUT); as well as a graphene based additive to fight corrosion on steel.

Earlier this year, Sparc and QUT said their multiple trials had produced anodes averaging about 45% higher reversible capacities compared to commercial hard carbon anode materials.

Image: Sparc Technologies

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.