Sparc Technologies says its collaboration with the Queensland University of Technology (QUT) targeting the development of a low-cost hard carbon anode material for the sodium-ion battery market is progressing well with initial test results averaging about 45% higher than project benchmarks.

Sodium-ion batteries are emerging as a viable alternative to the prevalent lithium-ion technology but current hard carbon materials used for the production of anodes are typically sourced from fossil fuel feedstock and energy intensive processes.

Sparc, which announced in September last year it would team with QUT on a research project to develop a sustainably sourced carbon anode material, believes it may have uncovered a viable alternative utilising green bio-waste and less energy intensive processes.

The South Australia-based company said QUT has delivered the first project report which describes the results of sodium-ion half-cell battery testing and material characterisation for the anode material under a range of conditions.

Image: Sparc Technologies

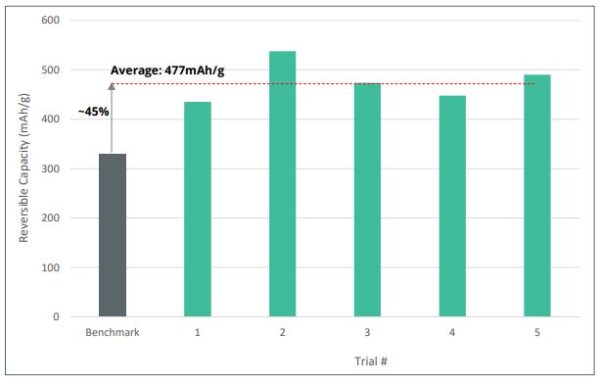

QUT said multiple trials have produced anodes averaging about 45% higher reversible capacities compared to commercial hard carbon anode materials.

Sparc said while further optimisation, testing and process development work is required, reversible capacities for a batch of materials tested under controlled conditions exceeded 535 milliampere hours per gram mass (mAh/g) and averaged 477 mAh/g across five separate trials.

Sparc Technologies Executive Chairman Stephen Hunt said the results are well above the benchmark of 330 mAh/g set at the beginning of the research program and auger well for the development of sodium-ion batteries which he believes have strong market potential, particularly in industrial and grid-scale storage.

“The combination of green bio-waste feedstock and faster, less energy intensive processing with a very high-capacity anode material offers attractive potential for further research and development,” he said.

“Equally as exciting is the continued progress of sodium-ion batteries towards commercialisation as evidenced by recent activities of major global battery producers including CATL, BYD and Reliance Industries.”

Sparc said while sodium-ion technology is still in its infancy, it represents a viable alternative to lithium-ion batteries, offering lower cost and greater availability of raw materials; safety and ease of transport; greater operating temperature range; and similar manufacturing techniques to lithium-ion tech.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.