Sparc Hydrogen has been awarded almost $500,000 (USD 315,000) by the Australian government to support the ongoing development of its photocatalytic water splitting (PWS) technology which employs the sun’s radiation and thermal properties to convert water into green hydrogen and oxygen.

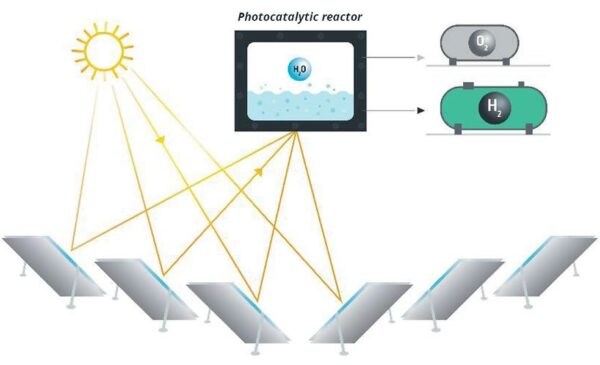

Green hydrogen is typically produced using renewable electricity to conduct electrolysis using an electrolyser. Sparc, a joint venture with clean energy tech company Sparc Technologies, the University of Adelaide and Fortescue, has developed a technique that entails solar radiation being directly applied to a reactor where PWS takes place.

Sparc said its approach, which uses only sunlight, water and a photocatalyst to produce green hydrogen, has the potential to improve the efficiency of PWS technology.

The company’s technique includes the use of the entire solar spectrum to enhance reaction efficiencies along with incorporating concentrated solar radiation via mirror reflectors, which has been shown to increase reaction efficiencies, while allowing for a reduction in the amount of photocatalyst material required for a given production rate.

Sparc has been awarded $470,511 under Australia’s Economic Accelerator (AEA) grant program to accelerate testing of a prototype PWS reactor unit that has already been installed at the CSIRO Energy Centre at Newcastle in New South Wales.

Image: Sparc Technologies

Sparc Technologies Executive Chairman Stephen Hunt said the funding reflects the “game-changing potential of the PWS technology under development.”

“This funding will enable Sparc Hydrogen to accelerate and build on laboratory-based testing and on-sun prototyping at the CSIRO,” he said.

“Sparc Hydrogen will also look at opportunities to participate in the subsequent phases of the AEA program, along with other funding programs to support the next stage of scale up as we progress towards commercialisation.”

Sparc said adopting the PWS process to produce green hydrogen has the potential to deliver a cost competitive advantage over electrolysis driven by renewable energy.

“Given lower infrastructure requirements and energy use, the Sparc green hydrogen process has the potential to deliver a cost and flexibility advantage over electrolysis, along with being more flexible and scalable,” the company said.

Sparc said two rounds of testing have already been completed at the CSIRO centre with both the reactor and balance of plant performing well at the planned upper limits of solar concentration and temperatures.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

2 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.