Producing hydrogen with an electrical input of less than 36 kWh per kilogram of hydrogen, a Commonwealth Scientific and Industrial Research Organisation’s (CSIRO) electrolyser pilot has successfully demonstrated its tubular solid oxide electrolysis (SOE) technology.

Conducted at steel supplier and manufacturer BlueScope Steel’s Port Kembla steelworks in New South Wales (NSW), the SOE technology operates unlike conventional hydrogen electrolysers, which rely on electricity to split water into hydrogen and oxygen.

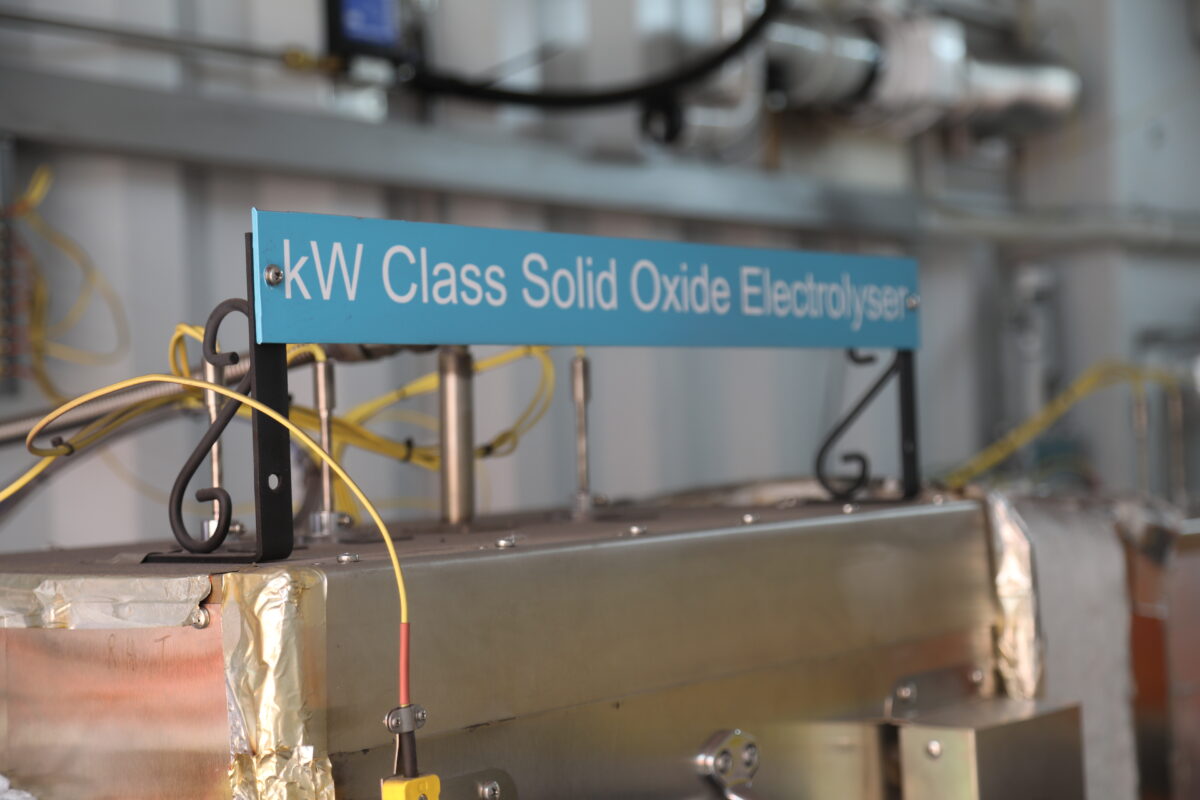

Image: CSIRO

Unlike alkaline (liquid) or PEM (polymer electrolyte) electrolysers, SOE uses both electricity and waste heat (for example, steam from the steelworks) to produce hydrogen with greater efficiency using a solid-state ceramic electrolyte.

SOE operates at temperatures close to 8000C, and if using existing waste heat from heavy industry to pre-heat the water going into an SOE electrolyser, 30% less electricity (<42 kWh/kilogram of hydrogen) is used.

CSIRO Senior Principal Research Scientist and Group Leader Dr Sarb Giddey said the trial produced hydrogen with an electrical input of less than 36 kWh per kilogram of hydrogen, by using the steam produced in the plant by the steelmaking processes.

“Since electricity takes up the lion’s share of variable production costs for renewable hydrogen, a substantial reduction in the electricity required (up to 30% saving) for hydrogen production could be a game changer for the nascent hydrogen industry,” Giddey said.

“Taking a new technology out of the lab and into the field can highlight unforeseen challenges, so we are delighted to see that our technology is meeting the performance requirements in terms of hydrogen production, electrical efficiency and reliability.”

Renewable equipment manufacturer Hadean Energy has licensed CSIRO’s SOE technology and is testing the long term durability and performance of the modular design at CSIRO’s hydrogen technology demonstration facility.

Following these successful trials, Hadean Energy is preparing to showcase a 5 kW demonstration unit as part of the Australia-UK Renewable Hydrogen Innovation Partnerships (HIP) to progress toward a large-scale industrial pilot.

Image: CSIRO

Hadean Energy Chief Executive Officer Chris Rowland said the tubular SOE technology has a further advantage of being inherently less expensive to build because of the simplified manufacturing process and more readily available materials.

“The 1000-hour milestone validates the technology in a real-world industrial setting, increasing the technology readiness level to prepare for commercialisation,” Rowland said.

“It shows the potential for Hadean Energy’s electrolyser to decarbonise hard to abate industries.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.