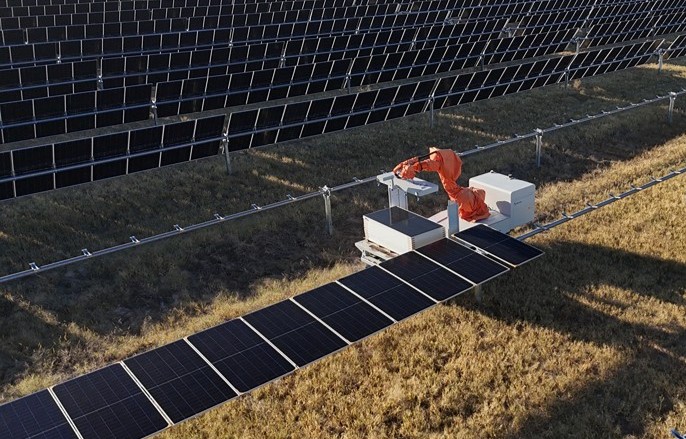

Chinese automation company Leapting has announced that its Automatic Navigation Solar Module Mounting Robot has completed its inaugural commercial project in Australia, successfully installing nearly 10,000 PV panels at the 350 MW Culcairn Solar Farm project being developed by Neoen in the New South Wales (NSW) Riverina region.

Leapting’s module-mounting robot was officially deployed at the Culcairn project site in early February and the company said it has since proven a major success, allowing for complete automation of the installation process and providing a significant shortening of the original construction schedule.

“It facilitated a 25% reduction in the project timeline while ensuring zero damage to both manpower and modules,” Leapting said in a statement, adding that the introduction of robot-assisted operations had increased installation efficiency “three to five times” compared to manual labour.

“Automation is shaping the future of large-scale solar deployment, making clean energy more accessible, and faster,” the company said.

Image: Leapting

The Automatic Navigation Solar Module Mounting Robot features a crawler chassis and an automated navigation system with obstacle detection. The machine uses a robotic arm to pick up and place solar modules weighing up to 30 kilograms on their supports. Its artificial intelligence-based vision recognition system identifies the position of the supports and adjusts the panel placement for precise fixing.

According to Leapting, manually installing a module typically requires between three and four workers and takes about 15 minutes while its robot can complete this process in just one minute per panel.

“This automated process not only significantly increases efficiency but also reduces the safety risks associated with manual labour, leading to an estimated 30% reduction in installation costs,” the company said. “That’s a huge advantage for solar developers, especially in regions where labour shortages and safety concerns are major issues.”

Leapting said the success of its robot at the Culcairn project sets a new benchmark for intelligent installation solutions for solar modules in both the Australian and global markets.

“The successful completion of this project not only marks a significant breakthrough for Leapting in the Australian PV energy market but also establishes it as the first exemplary commercial case in the field of intelligent module installation,” the company said.

The next test for the module-mounting robot is set to be substantially larger with Leapting confirming that it is to be deployed early next month to support the construction of an Australian solar farm that will involve the installation of nearly 500,000 PV modules.

Meanwhile, Neoen has announced that the Culcairn Solar Farm, backed by a long-term energy service agreement, is expected to supply its first solar electrons into NSW’s electricity network by mid-2025.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.