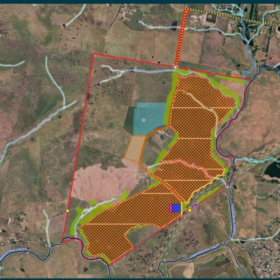

Bouygues Construction Australia (BCA) is trialling an autonomous piling system (APS) to build French renewable giant ENGIE’s 250 MW Goorambat East Solar Farm (GESF) in northern Victoria.

The Paris-headquartered engineering, procurement and construction contractor BCA, together with New South Wales (NSW)-based renewable energy solutions company Equans Solar and Storage, are trialling a United States-based automated equipment company Built Robotics’ APS to support the construction of approximately 500,000 solar panels at GESF, 212 kilometres northeast of Melbourne, near Benalla, Victoria.

Bouygues Construction Australia Project Director Bastien Sauvet said the APS boosts efficiency and accuracy by using AI, advanced global positioning system (GPS), and sensor technology to precisely drive piles with minimal human oversight.

“This marks a major step in automating utility-scale solar construction, reducing costs, and accelerating timelines while maintaining high safety standards,” Sauvet said.

ENGIE General Manager of Engineering and Asset Delivery Leigh Newbery said piling machine has exciting prospects for the future.

“It requires skilled technicians to operate it, thus upskilling the current renewable energy workforce and enabling more productivity,” Newbery said.

“The intended higher productivity will reduce the cost of renewable energy projects and enable projects to be built in less time – which will bring down energy costs for consumers and potentially allow more renewables to be built.”

Newbery said machines like the APC could also have benefits for solar farm construction in remote and inhospitable areas, such as deserts, where climate conditions are a risk to human staff.

“In the longer term, with continued development, machines like this will also enable a reduction in health and safety related risks from construction projects, including manual handling.”

Installed safety features of the technology include a geofence to isolate the robot from workers, lights and sounds to alert workers when the robot is active, both hardwired and wireless e-stops to instantly disable autonomy or shut off the engine and artificial intelligence (AI)-powered cameras for collision avoidance.

The robotic APS uses a technology that drives the structural piles into the ground, substantially reducing noise created by up to 20%.

“Autonomous robotic machines like this may also allow installation to occur around the clock, if noise impacts on local residents and near neighbours can be managed,” Newbery said.

Piling at GESF is expected to be complete in June 2025, and installation of the solar panels began in March 2025.

“Bouygues Construction Australia is managing the on-site works and we are currently peaking at approximately 240 people on-site for the construction, while our dedicated project team – including around 50 specialised staff in design, consulting, and management – ensures every detail is meticulously managed,” Newbery said.

Expected to be commissioned in 2026, GESF will have a generating capacity of up to 250 MW, or enough to power around 105,000 average homes.

Updated 2 May 2025, to include Equans Solar and Storage.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.