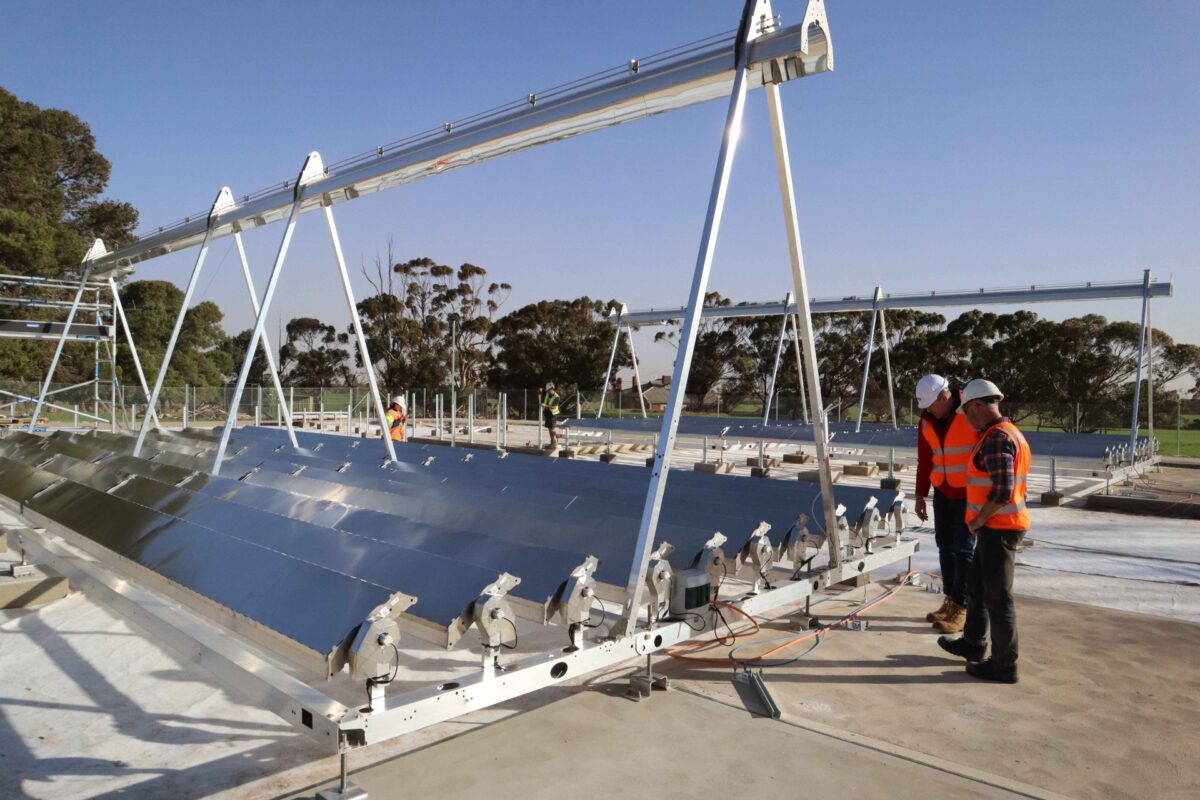

A first-of-its-kind pilot plant has been launched at the University of Adelaide’s Roseworthy campus by Australian startup Sparc Hydrogen as a test bed for photocatalytic water splitting (PWS) – a process that harnesses the sun’s energy to extract hydrogen from water molecules, without the need for electrolysers powered by electricity.

Sparc Hydrogen, a joint venture between the university, Adelaide-based Sparc Technologies, and energy and metals company Fortescue, said the Sparc Hydrogen Advanced Research Pilot (SHARP) plant will accelerate the development of the venture’s patented PWS reactor technology and will enable real-world evaluation of PWS catalysts being developed globally.

“The plant represents a first-of-its-kind demonstration and R&D facility globally for photocatalytic water splitting and is a key step towards commercialisation of the technology,” Sparc Technologies Managing Director Nick O’Loughlin said.

“In an environment where major challenges exist for hydrogen projects due to the high cost of power, the requirement for new solutions to unlock low-cost green hydrogen without relying on electrolysers has never been higher.”

Often referred to as direct solar-to-hydrogen technology, PWS avoids the need to convert solar energy into electricity to split water via electrolysis. In photocatalysis, the sun’s energy is directed onto a specialised photocatalyst material, that forms reactive sites that split water into hydrogen and oxygen without electrolysis.

Sparc said the technology is “a potential game-changer in the global effort to deliver scalable, low-cost, renewable hydrogen.”

Despite the promise of PWS, the efficiency of the technology remains a key challenge to reaching commercialisation.

Lead researcher and inventor Professor Greg Metha, acting director at the University of Adelaide’s Centre for Energy Technology, said the Roseworthy pilot plant aims to improve the economics of producing green hydrogen using PWS through driving increased efficiencies within modular and scalable concentrated solar infrastructure.

Metha said the facility will allow the technology to be evaluated at a meaningful scale ahead of potential commercial deployment in the future.

“The SHARP plant … will allow us to independently and concurrently test different reactor designs and photocatalyst materials,” he said.

“This next-generation photocatalytic water splitting technology has major advantages over electrolysis as it offers the potential to produce low-cost, scalable green hydrogen and heat without significant electricity use.”

Commissioning of the pilot plant is expected to commence in July. Once operational, the facility will be used to test different reactor designs and photocatalyst materials at in order to support and validate laboratory testing.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.