Melbourne-based clean tech company Cavendish Renewable Technologies (CRT) has unveiled its C-Cell electrolyser, saying it has been engineered to address cost, complexity, and efficiency barriers limiting the adoption of green hydrogen as an alternative to fossil fuels.

CRT said its C-Cell platform is based on an ultra-thin ceramic membrane electrolyte that delivers a high surface area for oxygen evolution, improved ionic conductivity, and long-term stability at elevated temperatures.

The company said the system is capable of operating at 100–150°C without the need for external heat sources and achieving up to 41.5 kWh per kilogram of hydrogen efficiency at stack level under real-world current densities. CRT said the system also minimises balance of plant requirements while simplifying installation and scale-up.

“A lot of solutions have been proposed, but very few deliver where it truly matters – on both performance and cost,” CRT Chief Executive Officer Dr Aniruddha Kulkarni said.

“With C-Cell, we’re not proposing anything that contradicts the laws of thermodynamics or depends on speculative science. It’s simply an elegant way of utilising internally generated heat during electrolysis to significantly reduce electrical energy input, without needing any external thermal source.”

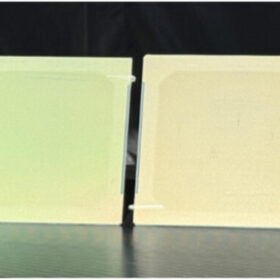

Image: Cavendish Renewable Technology

Kulkarni said comparable performance has only been achievable with solid oxide electrolysis systems operating above 800°C, a range that introduces serious challenges around heat integration and long-term material stability.

“C-Cell delivers similar benefits at a fraction of the temperature, with far greater practicality and scalability,” he said.

CRT said the C-Cell system leverages off-the-shelf components from filtration and battery industries, while its simpler overall system design reduces upfront expenses and lifecycle costs.

The company said the system is ideal for solar and wind coupling with the modular stack configuration, where each bundle of cells operates in parallel, allowing for finer load control and voltage flexibility.

Beyond hydrogen generation, CRT said the C-Cell’s membrane-electrode structure offers pathways for multiple applications including flow batteries for grid-scale storage using redox couples, and fuel cells with tubular proton exchange membrane (PEM) geometry for mobile and stationary energy solutions.

“We see the C-Cell not just as a product, but as a foundation,” Kulkarni said. “It’s a versatile platform built on strong IP, backed by deep testing, and ready to integrate into the next generation of clean energy systems.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.