Researchers from the University of New South Wales (UNSW), Sydney, have received over $4 million (USD 2.6 million) to scale up a next-generation electrolyser system that helps produce sustainable aviation fuel (SAF), using renewable energy.

The UNSW team have developed a carbon dioxide electrolyser system using low-cost transition metal and carbon catalysts, which can be integrated with the established Fischer-Trophsch (FT) process to produce sustainable aviation fuel.

FT is a chemical reaction that converts a mix of carbon monoxide (CO) and hydrogen (H) (syngas) into liquid hydrocarbons, and takes place at moderate temperatures and pressures.

To achieve further breakthroughs a $1.2 million through the Trailblazer for Recycling and Clean Energy (TRaCE) Australian Department of Education fund will aid moving the technology from technology readiness level (TRL) 4 (proof-of-concept in the lab) to TRL 6 (validated prototype in a relevant environment.

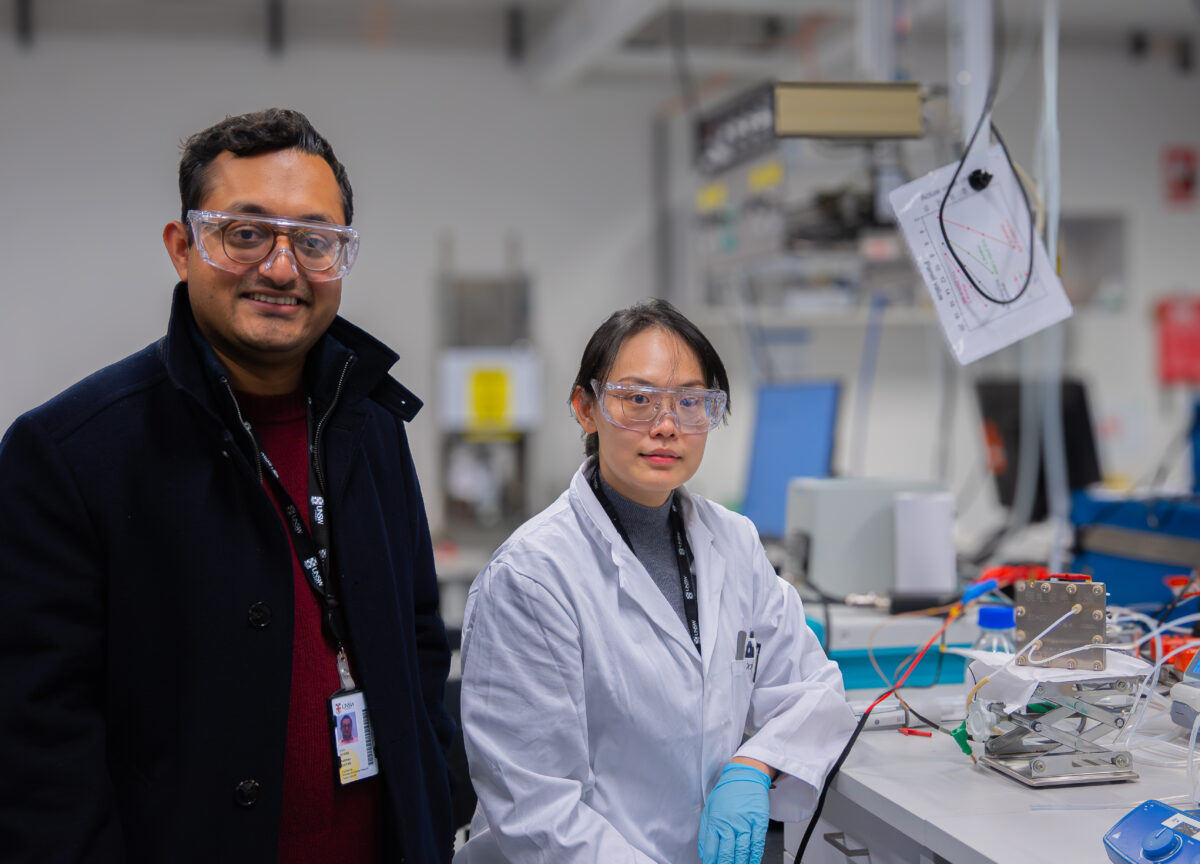

UNSW School of Mineral and Energy Resources Engineering Scientia Fellow and Lead Chief Investigator Dr Rahman Daiyan said the goal is to revolutionise how clean fuels for aviation are produced.

“The aim is to use renewable energy to transform carbon dioxide (CO₂) into usable fuels without requiring costly infrastructure changes,” Daiyan said.

“This technology could be the key to decarbonising aviation, one of the world’s most challenging sectors.”

Image: University of New South Wales Sydney

A spin-off company, called Gurung Fuel, will be funded and led by the research team’s industry partners, Sydney-headquartered energy solutions engineering company Tjindu Power, and Chinese clean tech developer Chuangqi Times (Qingdao) Technology Company.

Chuangqi Times (Qingdao) Adjunt Professor Yun said the partnership is a major step towards scaling the cutting-edge electrolyser technology.

“We’re not just developing a solution, we are creating a game-changer for the aviation industry, with the potential to make a global impact.”

UNSW School of Chemical Engineering Scientia Professor and Co-Director of the ARC Industrial Transformation Training Centre for Global Hydrogen Economy (GlobH2E) Rose Amal said of the low-cost transition metal and carbon catalyst development, that wast CO2 can be transformed into fuels that drive economies.

“It’s the kind of scalable innovation we need to tackle hard-to-abate sectors and achieve net zero,” Amal said.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.