“While solar cells have advanced dramatically in recent years, with more sophisticated structures and outstanding performance, the main quality inspection tool has remained largely unchanged for over a decade,” Hameiri said.

“The incumbent ‘current voltage’ testers must physically touch the fragile surface of cells, which often leads to damage. The method also struggles with current cell components such as multi-busbars, zero-busbars, and back contacts, as well as next-generation technologies like perovskite and tandem solar cells.”

Hameiri added that additionally, traditional testing methods can only be used in the late stages of cell production (post-metallisation), which means early-stage defects are missed and production is significantly slowed.

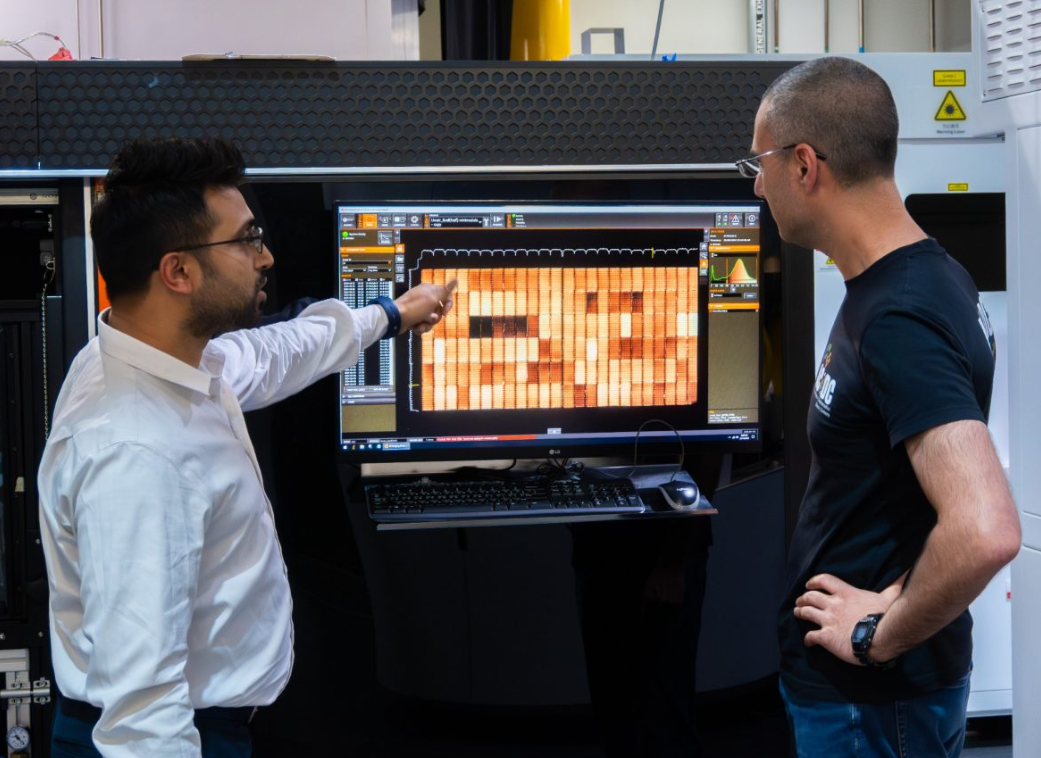

Image: University of New South Wales Sydney

Hameiri said the current testers were no longer suitable for measuring modern solar cells and faced even greater limitations with emerging technologies.

His team’s new system works by shining light onto a solar cell and analysing the faint glow it emits. This glow, or ‘luminescence’, reveals key electrical properties such as voltage, series resistance, and efficiency. Using advanced imaging and machine learning, test data can be converted into detailed maps of defects, performance and predicted lifespan.

“Through our collaboration with BT Imaging, we aim to reshape the industry by introducing contactless measurements that overcome the limitations of standard current-voltage testers, while offering lower cost, higher throughput and importantly, new insights that will make solar cells even more efficient and reliable,” Hameiri said.

The contactless system offers critical advantages over current testing methods: cells remaining intact during testing and defects can be detected earlier in production.

The technology works with both current silicon cells and emerging perovskite and tandem solar cells, making it a versatile solution for bringing next-generation solar technologies into mass production.

Taking technology from lab to market

BT Imaging Managing Director Dr Shubham Duttagupta said that as a UNSW spinout, the company is built on the strength of academic research, and partnerships like this allowed his team to keep pushing innovation into the marketplace.

“By combining UNSW’s cutting-edge innovation with our commercialisation expertise, we’re turning laboratory breakthroughs into practical, factory-ready products for both silicon and next-generation solar cells. We are creating inspection systems for manufacturers all around the world that are faster, more reliable, more accurate and future-proofed than ever before,” Duttagupta said.

The researchers are taking the solar cell inspection technology to market, thanks to a $400,000 grant from the Trailblazer Recycling & Clean Energy (TRaCE) Lab to Market Fund and a $1 million contribution by BT Imaging.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.