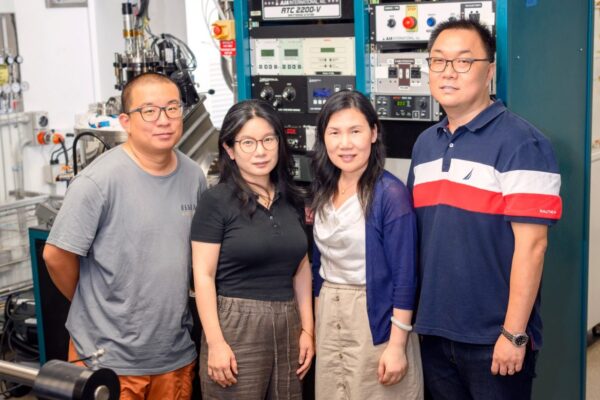

University of New South Wales (UNSW) researchers have developed a new method to monitor chemical bond changes in operating silicon solar cells as they degrade under ultraviolet (UV) light exposure and during recovery under visible sunlight.

The research team, led by Scientia Professor Xiaojing Hao, said the new non-destructive monitoring technique could help manufacturers test and certify solar panels more accurately and efficiently.

“This new method can be used directly on the production line to quickly check how well solar cells resist UV damage, making it useful for future quality control during manufacturing,” Hao said.

UV-induced degradation has resulted in efficiency losses of up to 10% in numerous silicon solar cell structures, including heterojunction (HJT), passivated emitter and rear cell (PERC), and tunnel oxide passivated contact (TOPCon). This degradation has been reported to be recoverable under certain conditions, such as light soaking, but studying such processes previously required cutting cells apart or relying on indirect electrical measurements.

The UNSW team used ultraviolet Raman spectroscopy, that utilises lasers to reveal a material’s molecular vibrations, to monitor chemical bond changes in operating cells exposed first to UV light and then to visible sunlight, enabling microscopic observation of damage and recovery processes.

“This technique works a bit like a camera. Instead of just measuring how much power the cell produces, we can directly see how the material itself is changing in real time,” said Ziheng Liu, corresponding author of the research paper published in Energy & Environmental Science.

“Normally we can only measure the power output. That has been observed already by many people, but with this new method we are also explaining the mechanism and we can see the change at a material level.”

Image: UNSW/Robert Largent

The technique revealed that UV light initially alters chemical bonds involving hydrogen, silicon, and boron near the cell surface, weakening passivation layers and reducing performance. When the cells were exposed to visible sunlight, the researchers observed that the material partially returned to its original state as hydrogen atoms migrated back toward the surface and broken bonds reformed.

“This confirms that recovery is not just an electrical effect,” Liu said. “The material itself is repairing at the atomic level.”

Liu said the ability to directly observe reversible material changes has major implications for module testing and reliability assessment.

“This approach helps distinguish between true long-term degradation and reversible changes,” he said. “That distinction is essential for accurate lifetime prediction.”

The researchers said the method also helps explain why some solar cells degrade more than others with design choices such as passivation layer thickness or surface coating properties affecting how hydrogen moves during UV exposure and recovery.

“This knowledge would allow manufacturers to make informed trade-offs between peak efficiency, durability, and cost,” they said, adding that the method could be used to screen new materials, processing conditions, or design changes before cells are built into full solar panels.

“This work gives us a clearer picture of how solar cells behave in the real world,” Hao said. “With better monitoring tools, we can design better tests, better panels, and ultimately more reliable solar energy systems.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.