Hydrogen Stream: Brits approach Australia to boost bilateral cooperation, Aussie engineers join asset-building consortium

Looking to deepen their hydrogen collaborations, the UK government last week spoke with Australian politicians. Meanwhile Australian engineer Worley has entered into an MoU with ABB and IBM to develop an “integrated, digitally enabled solution for facility owners to build green hydrogen assets more quickly, cheaply, and safely.”

Australia’s only panel manufacturer enters utility market with ‘world beating’ module

Tindo Solar, Australia’s only solar panel manufacturer, has launched its first module designed specifically for utility-scale projects, the 545W Karra module. Australia-made, the module boasts a 23.1% cell efficiency with a low cell-to-module loss rate of 0.07%.

Rooftop solar price to keep rising this year

British analyst GlobalData has predicted residential and commercial rooftop panels will not return to a declining price trend until next year, with post-Covid logistics headaches the cause, rather than a polysilicon shortage.

TOPCon vs PERC – a battle between fast learning curves

TOPCon solar modules will gain more market share if their average efficiency, already higher than that of PERC panels, continues to improve, according to Stefan Glunz, PV research chief at Germany’s Fraunhofer Institute for Solar Energy Systems ISE. In an upcoming pv magazine webinar on the potential of TOPCon tech, Glunz will show how to reduce costs and increase efficiency.

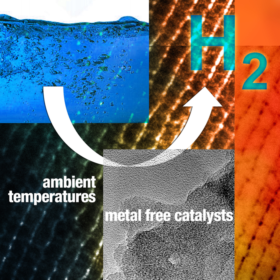

New dehydrogenation process to improve hydrogen storage

The U.S. Department of Energy’s Ames Laboratory launched a new catalyst based on nitrogen and carbon to extract hydrogen from hydrogen storage materials at mild temperatures and under normal atmospheric conditions. Furthermore, South African President Cyril Ramaphosa said that the country is working on attracting new investments in electric vehicles and hydrogen and Norwegian consultancy and classification society DNV launched, together with 18 industry partners, a new Joint Industry Project (JIP) to enhance the standardisation for hydrogen production systems that use renewable energy-powered electrolysis to produce green hydrogen.

Weekend read: Expansions in n-type

The past 12 months have been a turbulent time for PV manufacturing. Rapid and impressive developments in technology have been accompanied by price increases up and down the supply chain, and energy shortages weighed on production in the second half of the year. Chinese n-type module manufacturer Jolywood is now pressing ahead with ambitious expansion plans despite the disruption. pv magazine publisher Eckhart K. Gouras and editor Mark Hutchins recently caught up with Cathy Huang, European sales director at Jolywood, to discuss the company’s plans to bring n-type TOPCon technology into mainstream production.

‘Solar and wind deployment could not now be stopped if we wanted to’

BloombergNEF’s Jenny Chase has surveyed the state of affairs in world solar for clean energy journal Joule and said the technology’s historic ability to surmount obstacles – and persistently confound analysts’ predictions – should offer a reason for hope.

Zinc batteries: Old technology brings new values

In battery storage, there is no silver bullet chemistry type and as we move towards more ambitious decarbonization goals, room is being made for diverse systems. As an old technology with new vitality, zinc-based batteries are edging closer to commercialization, leveraging their unique ability to be configured for short and long duration operation. They are safer, longer lasting and, in some cases, reportedly up to 50% cheaper than lithium-ion batteries and, following recent game-changing advances, the prospects for zinc look much more exciting. pv magazine sat down with the manager of the newly established, global Zinc Battery Initiative, Josef Daniel-Ivad, to discuss the technology’s market position and developments.

Powering up PERC-perovskite tandem cells

Perovskite-silicon tandem cells offer one of the surest pathways to much higher solar efficiencies, one that has moved close to commercialisation in the past few years. Much of the work getting to this stage has naturally focused on developing a viable perovskite top cell. Optimisations to the silicon layer underneath, however, will also be important to the overall device function and efficiency. Scientists in Germany examined five different silicon cell concepts similar to those in mass production today, finding that with a few optimisations these could reach efficiencies up to 30.4%.

Sunday read: V2G driving grid changes

The uptake of EVs in the years ahead will add up to staggering battery capacity, mostly sitting idle on driveways. The two-way flow of electricity from EV batteries, known as vehicle to grid, could not only enable power systems to rely on intermittent renewables, but could also be the trump card for network operators to respond to grid disturbances. However, there are still a few catches to be worked out, as Marija Maisch explains.