Record solar numbers expected this year but IEA highlights pricing concern

The Paris-based body expects the world will have installed almost 160 GW of solar this year, a record number, but still not enough to keep the prospect of a net zero global economy by mid century in sight.

Saturday read: Getting smart about solar

As solar PV increases its share in the world’s energy mix, it is becoming increasingly clear how valuable the data gathered from renewable energy generators is in informing important decisions about operation, maintenance and grid integration. Yazeed Al Mousa examines the latest applications for artificial intelligence in PV project development and operation.

Jinko reduced module prices in the third quarter

The Chinese manufacturer appears to have shouldered higher input costs in return for carving out a larger slice of the world’s biggest solar market – although it’s not clear from the company’s third-quarter update that CEO Xiande Li received the memo.

Behind the price drops in lithium-ion batteries

Scientists in the United States pieced together data from hundreds of different sources, looking to establish the key factors that have led to consistently falling prices for lithium-ion technology since their commercialisation thirty years ago. They find that public-funded research, primarily in chemistry and materials science, has made the largest contribution to cost reduction. And they offer suggestions on policy and investment to ensure that the research can continue to make these important contributions to reduction in battery costs.

Phase-change material tech to store thermal energy, solar electricity in buildings

NREL scientists have unveiled a storage system based on a phase-change material that can store both thermal energy and electricity in a single device. According to the researchers, the new technology may be used to store excess electricity produced by on-site solar or wind operations in large scale buildings.

Sunday read: Forecast and prosper

At the risk of stating the obvious, PV performance will always be inextricably linked to the weather. Cloud cover significantly influences power output and severe weather events – including high winds, heavy snowfall, fire, and hail – can lead to module or structural damage. And with climate change making extreme weather events more common, the value of forecasting and understanding the worst Mother Nature can throw at a solar array is increasing.

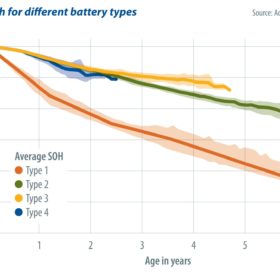

Saturday read: Battery performance, uncovered

Batteries are taking the energy world by storm. From residential home storage systems to large-scale installations, today’s society increasingly relies on powerful batteries. And, as we all know, with great power comes great responsibility. But, how can we ensure that our use of batteries today is responsible, cost-effective, or even safe? Kai-Philipp Kairies, CEO of Accure Battery Intelligence, shares some of his experience gained from monitoring more than 750 MWh of various storage applications.

Utilities and financial investors are investing in renewables, especially hydrogen, like never before

A new Ernst & Young power and utilities overview report shows that utilities and other deep-pocketed investors are putting financial support behind their environmental, social and governance initiatives.

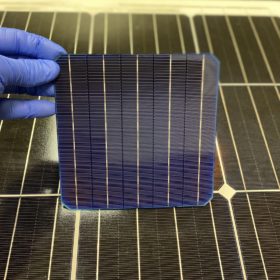

Novel solar cell architecture to reduce silver costs, improve voltage

Developed by a U.S.-based start-up, the new manufacturing process is claimed to reduce silver consumption and improve solar module performance by up to 3 watts. It consists of connecting sub-cells in series within a single cell in order to increase the device voltage and without requiring cells to be physically broken and rewired.

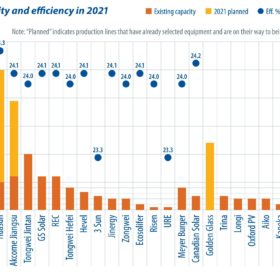

Saturday read: Looking past PERC

While the adoption of large-format wafers has driven a wave of capacity expansion for PERC, existing manufacturers and new entrants continue to evaluate TOPCon and HJT. An increasing number of HJT pilot lines and gigawatt-scale capacity expansion projects are appearing, as manufacturers see the advantages of fewer process steps, higher efficiency ratings, and better yield rates. The localisation of equipment is also a driving factor. PV InfoLink’s Derek Zhao offers an update on the latest developments and process routes for HJT.