New PV module recycling tech

French start-up Rosi Solar has developed an industrial solution claimed to be capable of recovering high purity silicon, silver and copper contained in end-of-life PV modules. The company’s technology is based on a pyrolysis process that makes it possible to isolate the different metals from the cells.

Novel PV module recycling tech from South Korea

Developed by the Korea Institute of Energy Research (KIER), the “non-destructive” technology is claimed to enable the recovery of 100% of a module’s glass and to allow the reuse of silicon for producing new solar cells with an efficiency of 20.05%.

New process to recycle silicon, silver and glass from end-of-life PV panels

A €4.8 million (AU$7.5 million) EU-funded research project is aiming to develop a process that allows recovering all components of a photovoltaic module.

Weekend read: The afterlife of solar panels

Use of the term “circular economy” is growing in virtually every industry worldwide – solar included. As noted throughout Q3, in the UP initiative’s focus on circular manufacturing, work is already underway to integrate circular principles into all areas of business, from internal operations and supply chain management to manufacturing and installations. In a recent analysis of PV recycling, BloombergNEF detailed six conclusions for the solar industry and those who are trying to make it more circular. Cecilia L’Ecluse, solar associate, and Julia Attwood, head of advanced materials at BloombergNEF share these conclusions as part of our quarterly theme on PV module recycling.

Understanding the fate of end-of-life modules

Scientists in India have taken a close look at the potential impact of growing volumes of PV waste, and have conducted surveys that suggest a lot more work is needed from manufacturers and policymakers to develop management systems for end-of-life PV products.

Australian scientists develop new transparent electrode material

Scientists in Australia have developed a new transparent conductive oxide which could be used in solar cells, smart windows and other applications. The material is indium free and recyclable, according to the researchers.

It may be safe to put PV panels in landfills, but that doesn’t mean we should

According to a new report from the International Energy Agency (IEA), health risks from lead in crystalline silicon PV panels are one order of magnitude — or about one-tenth — below the risk levels set by the U.S. Environmental Protection Agency.

Solar panel recycling: Turning ticking time bombs into opportunities

Australia has certainly demonstrated its appetite for solar power. Now, with the average lifespan of a solar panel being approximately 20 years, many installations from the early 2000’s are set to reach end-of-life. Will they end up in landfill or be recycled? The cost of recycling is higher than landfill, and the value of recovered materials is smaller than the original, so there’s limited interest in recycling. But given the presence of heavy metals, such as lead and tin, if waste is managed poorly, we’re on track for another recycling crisis. A potential time bomb could present itself as an opportunity, however, if the global EV industry showed an interest in the recovered solar products.

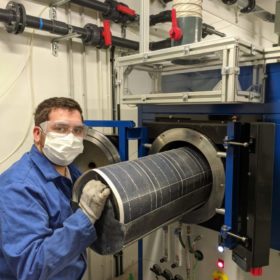

A mechanical technique for PV module recycling

An Italian consortium has developed a panel recycling process it claims can recover up to 99% of raw materials. The developers claim their technique takes only 40 seconds to fully recycle a standard panel, depending on size and recycling site conditions.

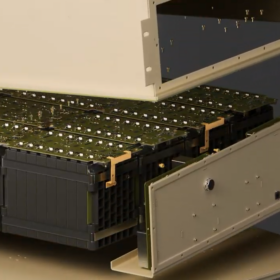

Deakin researchers find ‘Holy Grail’ of PV module recycling

Researchers from Deakin’s Institute for Frontier Materials claim to have solved the biggest problem that’s preventing photovoltaic cells from being recycled.