In what’s been described as a first-of-a-kind project, Element 25 will test the extent to which renewable energy solutions such as wind and solar could be used to power the electrowinning processes in the production of electrolytic manganese metal. The project proponents say it could potentially pave the way for new opportunities for renewable energy integration into the metals processing and potentially open up export markets.

The project has won the backing of the Australian Renewable Energy Agency (ARENA), which has allocated $490,000 in funding. “The resource processing sector is an area in which there is currently low penetration of renewables,” said ARENA CEO Darren Miller. “The use of renewables could be expanded to other types of metal processing, increasing the opportunities for Australia to export renewable energy or emission-free resources to the world.”

Noting that Australia is currently the third largest producer of manganese ore, Miller explained that if the project shows renewables are a viable option it could even create a new industry in Australia. Ore processing, utilizing low cost renewable energy sources could add value to homegrown resources, rather than shipping raw materials overseas – with the processing powered by fossil fuels.

Integration of renewables into the downstream processing of high value ores

Electrowinning is an upgrading process where an electric current is passed through a metal salt solution causing the metal to be deposited in an electroplating process. It traditionally relies on grid connected power sources.

In the ARENA-backed project, Element 25 will investigate the impact on the electrowinning process utilising high levels of variable energy supply from wind and solar, requiring the process to respond dynamically to the changes in power output. The study will be part of the company’s Butcherbird development, Australia’s largest onshore manganese resource to be located 130 km south of Newman, Western Australia. Pre-feasibility studies are being carried out for the project and are scheduled to be completed by the year’s end.

“Making metals with renewable energy makes sense. If successful, this work will have a significant impact on our project economics, but will also pave the way for other Australian companies to integrate renewable energy into their resource projects to add value right here in Australia,” Element 25 Executive Director Justin Brown said.

Since the electrowinning of metals (including manganese, but also copper, zinc and others) requires a significant power input, renewably generated power makes economic sense in terms of project economics. Work completed to date under the pre-feasibility study has shown that whilst the availability of natural gas at Butcherbird provides a robust base case, the best economics in relation to power generation are achieved via a combination of wind, solar and gas.

The ARENA funding will contribute 50% of the total budget of $980 000 to demonstrate the viability of Intermittent Dynamic Electrowinning (IDE), which allows manganese metal to be produced under dynamic condition, the company said in a release. Base case analysis without IDE indicates that up to 60% renewable penetration is possible, but IDE is expected to show that up to 90% renewable penetration may be possible, with significantly improved economics.

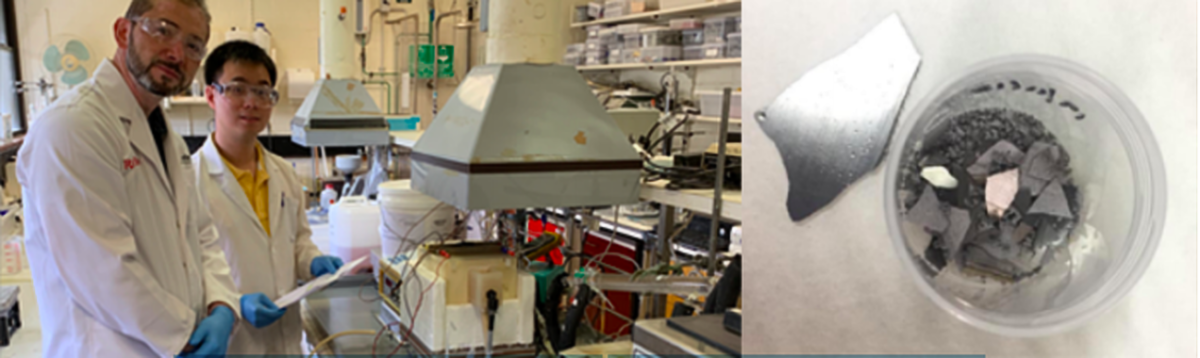

The project will involve lab scale tests, field studies to collect solar and wind resources and a pilot study to examine how manganese production will respond to actual solar and wind data collected in a full scale test. The test work will be undertaken at the Murdoch University (College of Science, Health, Engineering and Education) Extractive Metallurgy Division.

Element 25 has engaged advisory consultants Advisian to identify a mix of renewable energy sources as the low-cost power solution for the project, and assist with the approval of the ARENA funding.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.