A single-atom-thick layer of carbon atoms arranged into a hexagonal formation, called graphene, comes with the ability to transport a charge much faster than most other materials. There is a plenty of ongoing research into graphene, and the sustainable synthesis of high-quality graphene sheets is one of the hottest and most inspiring topics.

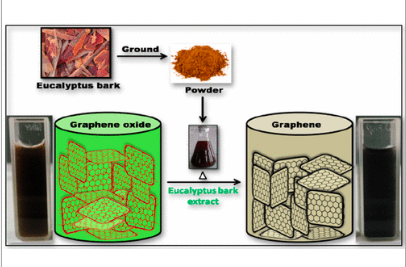

The new approach developed by researchers from RMIT University (Australia) and the National Institute of Technology, Warangal (India), uses eucalyptus bark extract to synthesize graphene, which makes it cheaper and more sustainable than current synthesis methods. RMIT lead researcher, Suresh Bhargava, said the new method could reduce the cost of production from $USD100 per gram to a staggering $USD0.5 per gram.

“Eucalyptus bark extract has never been used to synthesise graphene sheets before and we are thrilled to find that it not only works, it’s in fact a superior method, both in terms of safety and overall cost,” he said, adding the abundance of eucalyptus trees in Australia makes it a cheap and accessible resource for producing graphene locally.

Graphene’s distinctive features make it a transformative material that could be used in the development of flexible electronics, more powerful computer chips and better solar panels, water filters and bio-sensors. “It is a remarkable material with great potential in many applications due to its chemical and physical properties and there’s a growing demand for economical and environmentally friendly large-scale production,” Bhargava said.

The thinnest and strongest material known to humans, graphene is also flexible, transparent and conducts heat and electricity 10 times better than copper, making it optimal for anything from flexible nanoelectronics to better fuel cells. While it makes a good case for the development of highly efficient, ultrathin solar cells, graphene has been beset by extremely short carrier lifetime. With electrons excited by sunlight mobile for only one picosecond (one millionth of a millionth of a second), scientists are also looking into methods to gain better control over the lifetime of the excited electrons.

The greener method

Presently, chemical reduction is the most common method for synthesising graphene oxide as it allows for the production of graphene at a low cost in bulk quantities. This method however relies on reducing agents that are dangerous to both people and the environment.

Professor Vishnu Shanker from the National Institute of Technology, Warangal, said the ‘green’ chemistry avoids the use of toxic reagents, potentially opening the door to the application of graphene not only for electronic devices but also biocompatible materials.

In their experiment, researchers used a eucalyptus polyphenol solution obtained from a eucalyptus bark extract to trigger the reduction of exfoliated graphene oxide to soluble graphene under reflux conditions in an aqueous medium. This led to an effective removal of the oxygen functionalities in graphene oxide.

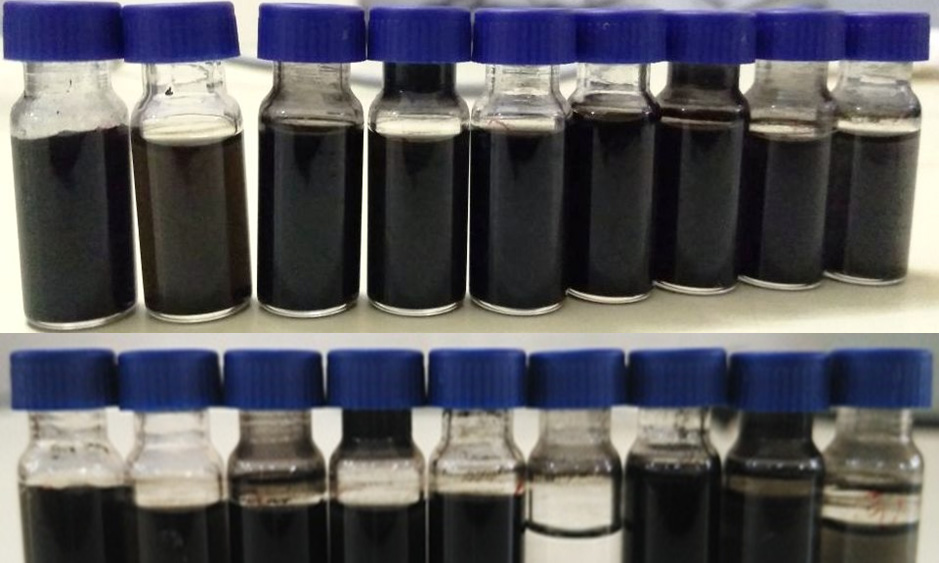

When tested in the application of a supercapacitor, the ‘green’ graphene produced using this method matched the quality and performance characteristics of traditionally-produced graphene without the toxic reagents.

The findings can be seen in the paper titled, Novel and Highly Efficient Strategy for the Green Synthesis of Soluble Graphene by Aqueous Polyphenol Extracts of Eucalyptus Bark and Its Applications in High-Performance Supercapacitors published in the ACS journal Sustainable Chemistry and Engineering.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.