Product stewardship of Australia’s existing and future energy infrastructure is a critical consideration for the solar industry and for government. Engineering and design company Arup has applied foresight and the concepts of least-waste circular economics to Australia’s current and future solar infrastructure in a new report: Circular photovoltaics.

Published late last year, the report was produced to inform the company’s advice to businesses, councils and governments on the feasibility and responsibilities of solar projects, and to provide best-practice context for dealing with the solar waste stream, says Michael Salt, one of the report’s authors.

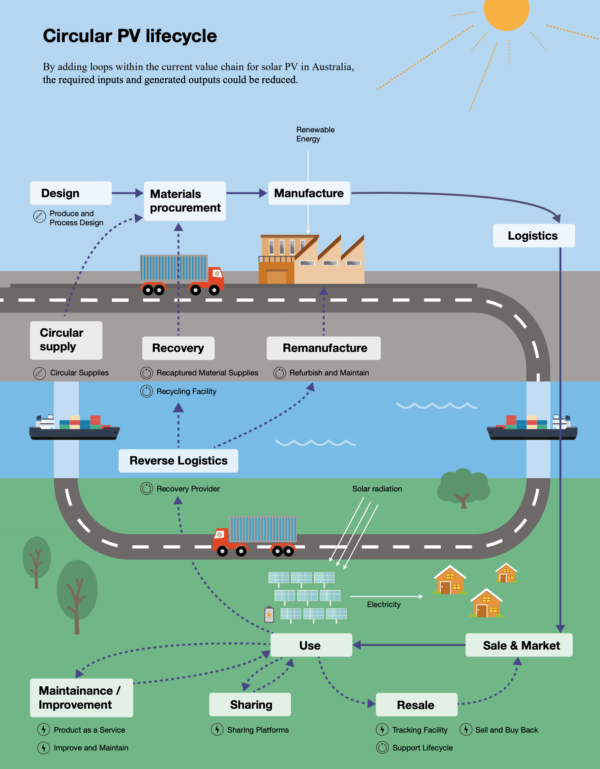

A Senior Energy and Economics Consultant at Arup, Salt told pv magazine today that the circular economy and solar waste are being discussed at every level of government, and that the research he and co-author engineer, Emily Gentilini have produced confirms that, “Diverting solar waste from landfill requires a system-wide approach that includes design of solar product, how we use that product, and recovery of materials” when the product can no longer be used.

As such, Circular photovoltaics poses five Circular business models for Australia’s photovoltaics industry, in line with United Nations’ Sustainable Development Goals (SDG). For example, SDG 12: Responsible Consumption and Production, refers to the need to do more with less to achieve better worldwide social and environmental outcomes; and SDG 7 calls for global supply of affordable, clean energy.

First-generation first

In anticipation of 300,000 to 450,000 tonnes of PV waste entering the Australian waste stream by 2040, the Arup report urges an immediate focus on recovery of materials from first-generation crystalline silicon technologies.

In mid-2019, pv magazine spoke with Maryanne Coffey, Emerging Technologies and Project Manager at Australia’s Clean Energy Council, who is formulating strategies and guidelines to assist the CEC membership of solar installers in following best practice for end-of-life or returned-under-warranty solar infrastructure.

Coffey noted that solar panel recycling is potentially a big employer, and effective management of the waste stream could lead to manufacturing opportunities in Australia. For example, she said, “In Europe, [US PV manufacturer] First Solar recycles where it manufactures, so the retrieved components go straight back into the production line. That’s the gold standard!”

In proposing a ‘Circular design’ model for future solar technologies, the Arup report says “focus should also be placed on the early lifecycle stages (i.e. design) of second and third generation panels to consider how waste can be firstly designed out, and secondly whether they have been manufactured for maximum reparability, reusability and recyclability”.

This requires a level of collaboration between manufacturers to standardise panel assembly methods across the industry, with a focus on easy separation of parts, thereby simplifying end-of-life material recovery.

Manufacturers currently have no incentive to collaborate on such design initiatives, but the industry could begin by researching and formulating “design for disassembly principles”, say the Arup report authors, and governments can enable the process by legislating to “encourage manufacturers to close the loop on their supply chains”.

Australia and the PV product stewardship continuum

Photovoltaic panels have been on the list for consideration under Australia’s Product Stewardship Act since 2016.

A final PV Stewardship Options Assessment was completed by sustainability consultancy Equilibrium and provided to the agency tasked by the Federal Government with progressing PV product stewardship, Sustainability Victoria, in March 2019.

“They now have to produce a Regulatory Impact Statement examining the options,” says Salt, who consulted with Sustainability Victoria and others in formulating Circular photovoltaics. As such, he adds, “It will take another year or so to determine the correct mechanism for this product stewardship.”

Arup concludes its discussion of the circular design model, by pointing out that since Australia currently imports more than 70% of its solar panels from China, Malaysia and Singapore, “the Australian sales and installation industry will need to work within the Asia-Pacific region to establish goals, design priorities and collaborations required for better product and process design.”

Meanwhile solar industry leaders in the US have been working on a leadership standard for sustainability performance of PV modules — NSF/ANSI 457 Sustainability Leadership Standard for Photovoltaic Modules — a final draft of which is imminent, and is expected to serve as a global benchmark for the industry.

Getting more solar bang for our buck

Circular photovoltaics also outlines models for Circular use of PV, such as community solar or virtual power plant sharing platforms that enable more people to utilise existing and future solar assets, rather than promoting further individual ownership and use of rooftop solar systems.

And its Refurbish and maintain model centres on assessing panels returned under warranty or discarded before end of life; the potential for repairing them; and the need for a low-cost system of testing and verifying their efficiency and projected ongoing lifespan, to establish a trustworthy second-hand panel market.

Testing of refurbished panels, which currently “can be in the order of the cost of the panel itself in Australia”, write the Arup authors, is also vital to the insurability of systems that include secondhand panels.

Not another continental soup!

The report calls for “Clear and standardised rules across Australia for collection, repair, resale and recycling of solar PV panels”, to enable both efficient refurbishment and ultimate recycling of PV materials.

Currently, Victoria is the only Australian state to have banned disposal of e-waste, including solar panels, batteries and inverters, in landfill, thereby clearly signalling the need for recycling. But a co-ordinated approach is required to prevent dumping of waste across state lines, and to concentrate and grow the market potential for investment in material recovery from solar infrastructure.

The viability of solar-panel recycling

In April 2019, research published by the University of New South Wales (UNSW) found that under certain circumstances, the process of recycling solar panels can be profitable, scientifically showing the potential for a viable solar recycling industry.

Professor Chee Mun Chong, Professor at UNSW’s School of Photovoltaic and Renewable Energy Engineering, and a co-author of the study, A techno-economic review of silicon photovoltaic module recycling, listed conditions in line with those identified by Arup as supporting Circular photovoltaics:

- simplified and improved recycling processes focused on increasing rates of materials recovery — particularly of silver and intact silicon wafers

- changes to module design that better facilitate recycling

- consideration by manufacturers of how to incorporate second-life materials into their production lines

- and a co-ordinated approach by governments and recyclers to building the recycling network

The body of evidence is growing to support action by government to facilitate the most sustainable energy generation possible.

As Salt told pv magazine, “It’s not just about formulating a policy, it’s about enabling the industry. It’s not saying, ‘You have to be responsible for the costs.’ We don’t want regulation to obstruct the industry and thereby reduce the benefit of making this cleaner form of energy available to everyone.”

He says Arup intends to integrate the knowledge gained on circular economies into client projects, in collaboration with the solar industry.

Read more about how the global PV industry can double down on its green credentials, by following pv magazine’s UP initiative as it continues into 2020.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

“Coffey noted that solar panel recycling is potentially a big employer, and effective management of the waste stream could lead to manufacturing opportunities in Australia. For example, she said, “In Europe, [US PV manufacturer] First Solar recycles where it manufactures, so the retrieved components go straight back into the production line. That’s the gold standard!”

First Solar did this several years back. Could it be the type of solar PV ‘chemistry’ used CdTe or could any silicon solar cell be recycled in almost the same way? Depending on the technology used, recycling as in the form of ‘plastics’ has about a 20% to a high of 40% recycling rate. So, plastics recycling that has been around for what, two to three decades is still leaving 80% to 60% of all plastics as part of the waste stream. Will have to do a lot better than that with solar PV recycling.

Culver City United States – Network Engineer – Maintain technical expertise in all areas of network : Maintain technical expertise

in all areas of network and computer hardware and software interconnection and interfacing https://ma9.biz/

Hello, thank you for sharing this article it will be really helpful for me to understand about an Arup report on photo valtaics and the circular economy. I appreciate your step for choosing this topic. Great article!! You have done a good research I must say, thank you very much for sharing this article.