There has been a growing call from the Australian PV industry to change solar power system installation and equipment standards, particularly with regard to unpopular DC isolators. Often referred to as the weakest link in the rooftop PV safety, DC isolators were mandated in Australia in 2012.

Together with its Australian partners Solaray and AC Solar Warehouse, Enphase Energy has backed the industry’s calls for rooftop PV safety. As the microinverter producer explains, to operate the rooftop DC isolators used in Australia, emergency services personnel must climb onto a roof that may already be dangerous to access. In addition, even with a switched isolator, the cabling under the panels remains fully energized up to 600 volts DC.

“Evidence suggests that approximately 65% of conventional DC solar system failures occur at the rooftop DC isolator,” said Grant Behrendorff, managing director of AC Solar Warehouse. “There is widespread support across the Australian solar industry to address the issue as international standards are put in place along with newer technologies that eliminate the need for rooftop DC isolators.”

Since the Standards Committee is yet to undertake a full review and decide as to whether the installation of DC isolators should continue to be mandatory, the industry has been lobbying against this safety mechanism that has caused more harm than good.

“Rooftop DC isolators were made mandatory through AS/NZS 5033 in 2012,” the Clean Energy Council said earlier. “Since then, rooftop isolators have been proven by inspection data to be the largest single source of PV system failure.”

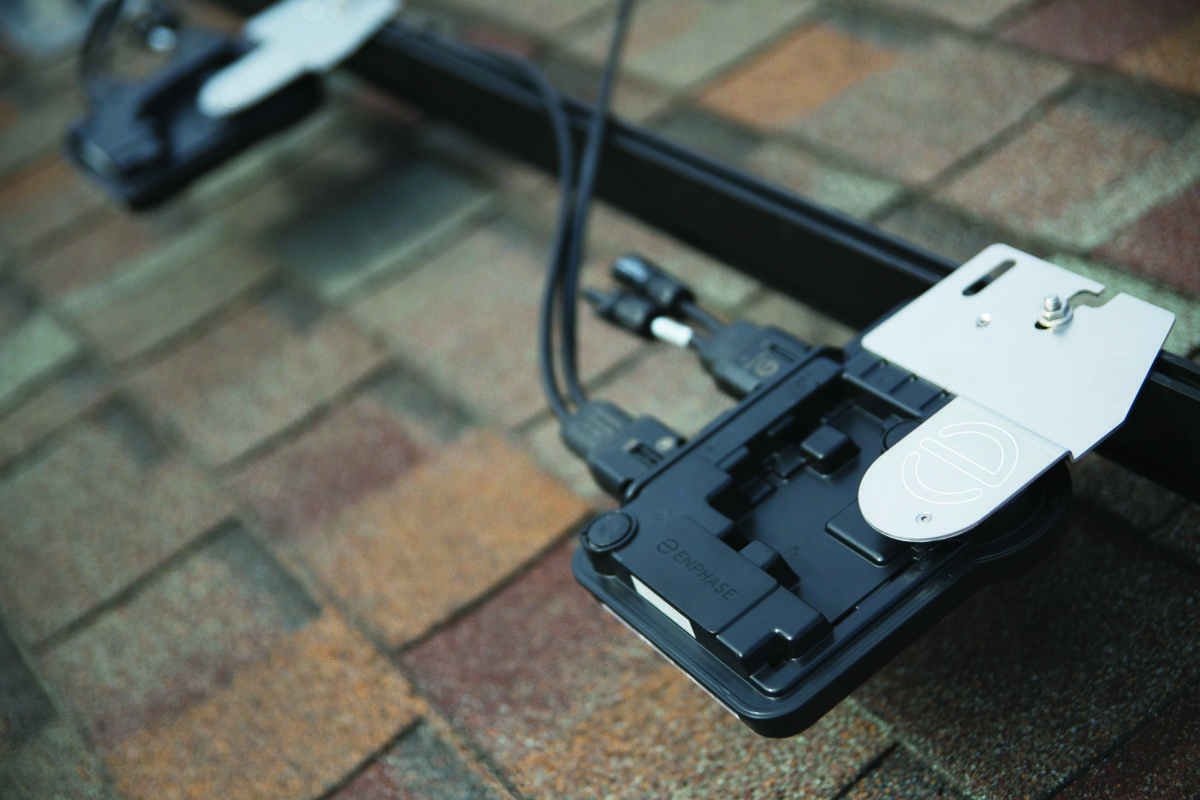

The simple solution to avoid DC isolators is to install a microinverter system that does not use high voltage DC, such as Enphase’s solution. Enphase IQ microinverters are arc fault detection and rapid shutdown compliant equipment, which provides a quick and easy method to de-energize PV modules to ensure complete safety for first responders and eliminate the risk of electrocution. Rapid shutdown capability is built-in, with no additional equipment necessary.

“It is no surprise that smart solar systems such as Enphase dominate the market in countries like the United States, where safer solar regulations have been adopted quicker than here in Australia,” said Jonathan Fisk, director at Solaray. “Of course, front of mind is the increase in panel-level output delivered by Enphase microinverters, but for many customers it is the story around safety that really gets their attention.”

Enphase IQ microinverters meet regulatory requirements set by the U.S. National Electrical Code (NEC), which currently represents the international solar safety benchmark the Australian PV industry is working to achieve.

“Enphase fully supports initiatives focused on bringing Australian PV installation standards in line with global best practices,” said Dave Ranhoff, chief commercial officer at Enphase Energy. “2019 was a record growth year for rooftop solar installations in Australia, and the trend is set to continue this year. With industry sales at an all-time high, it is now time to raise the bar on safety.”

Last year, the final tally was 2.13 GW of sub-100kW systems registered following a record installation surge in December, according to solar analyst SunWiz. This represents a jump of 35% year-on-year and puts the grand total at 10 GW.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

“The simple solution to avoid DC isolators is to install a microinverter system that does not use high voltage DC, such as Enphase’s solution. Enphase IQ microinverters are arc fault detection and rapid shutdown compliant equipment, which provides a quick and easy method to de-energize PV modules to ensure complete safety for first responders and eliminate the risk of electrocution. Rapid shutdown capability is built-in, with no additional equipment necessary.”

With smart ESS becoming the next ‘thing’ in solar PV systems on homes and businesses, the 48 VDC system may push out the old higher voltage DC strings typically used in older grid tied systems. I believe this could also address the “rapid disconnect” concept in solar PV wiring. Bring the whole 48VDC buss down to a knife switch on an exterior wall, where the Fire department could “decouple” the roof panels from the solar PV system buss, including the battery backed ESS.