From the April edition of pv magazine

So often we get asked this seemingly simple question: What is the best battery? But before we go into the answer, let’s discuss the origins of the question itself. In recent years there has been a surge in interest in battery storage, from residential to utility-scale. In Australia in particular, this interest has been driven by increasing electricity prices as well as state government subsidies. Internationally, improvements in battery performance, reductions in battery system costs, and the expansion of the number of system options available has increased the uptake of home battery systems.

Understandably, consumers and investors want to know which battery systems perform well. However, the performance of new battery technologies is something that many end-users remain unsure about. Even within specific technologies, the number of manufacturers and models is increasing and it can be overwhelming knowing who and what to believe in terms of performance claims.

In 2015, although there were far fewer residential and commercial products available on the market than today, lithium-ion was already recognized as a storage technology with potential, and an emerging competitor to the incumbent lead-acid technology. However, there was very little publicly available information on the performance of lithium technology in installations outside of manufacturers’ lab tests and over a significant period of time.

The ITP trial

The ITP Battery Trial was funded by the Australian Renewable Energy Agency (ARENA). It aimed to address this information gap. Designed, built and operated by ITP Renewables, the Battery Trial involves cycling battery packs at an accelerated rate in ambient temperatures that reflect the daily temperature cycles across many Australian climates. Information is collected for each battery on cost; ease of procurement, installation, and commissioning; technical performance including round-trip efficiency and capacity; and operational performance, including any interruptions to cycling, faults or required replacements. The findings are published every six months in a public report.

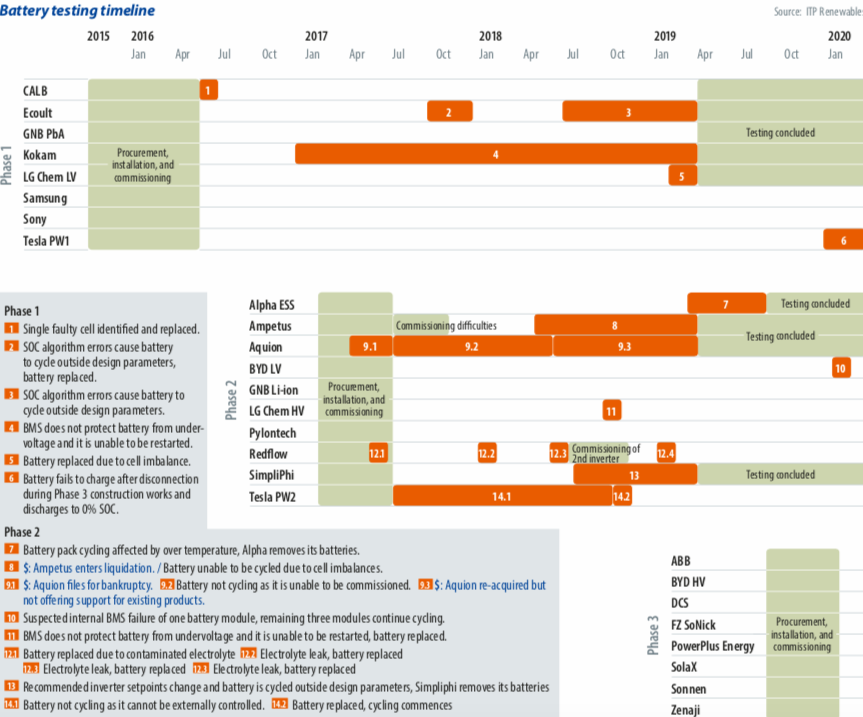

The Battery Test Centre facility is located at the Canberra Institute of Technology (CIT). Phase 1 of the trial started in mid-2016 and included eight batteries, with a further 10 batteries installed as part of Phase 2 in mid-2017. An additional eight batteries will be installed at the end of 2020 under Phase 3, facilitated by the removal of batteries which have either finished their original testing period or are no longer cycling.

The batteries are mostly lithium-ion – either lithium iron phosphate (LFP) or nickel manganese cobalt (NMC) chemistries. But they have also included lithium titanate (LTO), lead-acid, lead-carbon, aqueous hybrid ion, zinc-bromine flow, and sodium nickel chloride technologies.

However, in the four years since its inception, what started as a project to compare the performance of lithium-ion technology to lead-acid technology, has shifted toward providing independent assessments of the reliability and performance of a range of battery storage technologies on the market, as stakeholders have continued to ask about testing results, while also suggesting new batteries for inclusion.

Trial findings

The diagram above shows some of the problems experienced by batteries in the ITP Trial since late 2015. Although the project originally focused mostly on quantitative results such as capacity fade, it has become clear over more than four years of operation that there are a large number of factors which contribute to a high-performing, reliable battery storage system.

Cycle life

One of the most common metrics consumers use to try to differentiate between different battery packs is cycle life; that is, the number of charge/discharge cycles that can be completed before a battery reaches the end of its useful life. For many storage technologies, the amount of energy that can be discharged from the battery decreases (or fades) with time and/or energy throughput.

BMS problems

Compared to lead acid, lithium cells are more vulnerable to damage when operated outside of design parameters, including under/over-voltage, over-current, and under/over-temperature. The battery management system (BMS) is responsible for monitoring the internal cells and protecting them from any of these conditions. This is not a trivial operation, and more than one battery in the trial has experienced operational failure due to BMS problems.

Thermal regulation

Lithium-ion capacity fades more rapidly at elevated temperatures. Battery manufacturers have addressed this in a number of ways. Most batteries in the trial have passive cooling only, while some have active cooling. Others limit the charge/discharge rate when the battery is above certain temperatures.

Inverter integration

Integration of lithium-ion batteries (and other newer technologies) with older inverter products has proven troublesome. Many lithium batteries come with a list of ‘compatible’ inverters, but the inverter list of ‘compatible’ batteries may not match; in some cases, no such lists are available. Some manufacturers state compatibility, but it is not clear that the battery has ever been tested with the inverter in question. These batteries may still operate to some extent with the inverter, but not optimally.

Track record

The ability of manufacturers to resolve issues experienced by batteries in the ITP Trial has varied greatly. A large number of manufacturers are entering the market who either do not have a history in lithium-ion technology (and may underestimate its complexity), or are not established enough to guarantee the availability of support over an extended timeframe. One or a combination of these two characteristics may be a risk.

Best battery

So which is the best battery? Although tha is a complex question that we can’t (and don’t try to) answer, it’s clear that the appetite for independent battery testing results remains. The ITP Battery Trial results should not be assumed to be representative of product performance, as only one of each unit is tested, and the batteries are cycled more rapidly than would be expected for most applications.

However, the testing does provide an indication of the state of the battery storage market as a whole. As the industry develops, and until installations in the field have been operating for long enough to provide meaningful data, we will hopefully see other variations of independent testing. This, along with the developments in battery installation standards and battery performance testing standards that are already underway, will surely result in better quality within the industry.

The views and opinions expressed in this article are the author’s own, and do not necessarily reflect those held by pv magazine.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

I did not see Eguana Technologies mentioned, they were one of the first companies selling battery storage. Eguana gave Sonnen their first battery storage system in Germany, followed by Tesla in 2014/2015.