Anita Ho-Baillie and her team at the University of Sydney are working to recreate the impressive efficiencies that have been achieved with small perovskite solar cells on larger devices, by using industry-compatible processes.

Perovskites offer some very appealing physical and chemical properties that make them ideal materials for solar cell applications. These include broad absorption spectrum, wide bandgap, fast charge separation, high charge-carrier mobilities, long diffusion lengths, low processing cost, flexibility, light weight and semi-transparency. Hence, perovskites have now become the lab champions for “third-generation” photovoltaics.

But it is not all roses for PSCs. They have drawbacks such as sensitivity to oxygen and moisture, short lifespans, low efficiencies when scaled up, and the presence of lead in the perovskite crystal.

Inside a PSC

In a PSC, perovskite crystal is the active light harvesting ingredient. However, other structures within the device, such as electrodes and charge transport layers, also play crucial roles in ensuring the flow of current.

Much research has gone into wafer-based solar and thin-film PV, and perovskites have made an entry with great timing, further enabled by the incredible research already being done across the solar community. On that note, PSCs can also take the form of different solar designs such as tandem, organic heterojunction (HJT), single junction, with its very initial architecture being that of a dye sensitized solar cell. Moreover, PSCs can be processed using various techniques such as solution and vapor deposition, roll-to-roll processing, and spin coating, to name but a few. PSCs also have the attractive advantage of either being rigid or flexible.

Researchers are trialing new techniques and combinations of materials to enhance the efficiency and stability of PSCs. The Korea Research Institute of Chemical Technology and Massachusetts Institute of Technology holds the highest power conversion efficiency for PSCs at 25.2% for a single junction cell. For perovskite-silicon tandem design, the highest power conversion efficiency sits at 29.1%, achieved by Helmholtz-Zentrum Berlin.

Toward commercialization

For a solar cell to be fully commercialized, three key elements must be satisfied: high efficiency, low processing cost, and reliable stability. Under lab conditions, PSCs are a winner in the first two, but have struggled with stability. However, earlier this year, for the first time ever, a team of researchers from Solliance in the Netherlands managed to pass three established lifetime tests with scaled perovskite solar modules. The Solliance team’s encapsulated perovskite modules, fabricated using what the insitute describes as industrial processes, withstood the light soak, damp-heat, and thermal cycling tests. This is a significant leap for PSCs, and a giant step toward commercialization.

To further reduce cost and enhance performance, researchers are trialing various charge transport layers, such as nickel oxide and copper oxide for hole transport layers, as well as zinc oxide for the electron transport layer. For electrodes, graphene is used to replace expensive gold anodes and carbon is being experimented as a cathode alternative.

Doping is another technique being used, whereby potassium is introduced in perovskite crystals to allow sunlight to trigger a healing process – reducing defects and increasing stability. Research is also being done on finding perovskites with a high absorption coefficient, understanding electron dynamics, lead-free PSCs, nano crystals, and quantum dots.

Lead is a problematic area for PSCs. However, researchers are working toward reducing the amount of lead and replacing it with tin. This lead-tin combination can open up new possibilities for reducing toxicity, and also reduce the band gap further to increase the PSC efficiency.

Various companies and startups such as Oxford PV, Hunt Perovskite Technologies, Swift Solar, Iris Photovoltaics, Microquanta and others have started to emerge worldwide, looking to get a slice of the perovskite pie.

Flexible PSCs

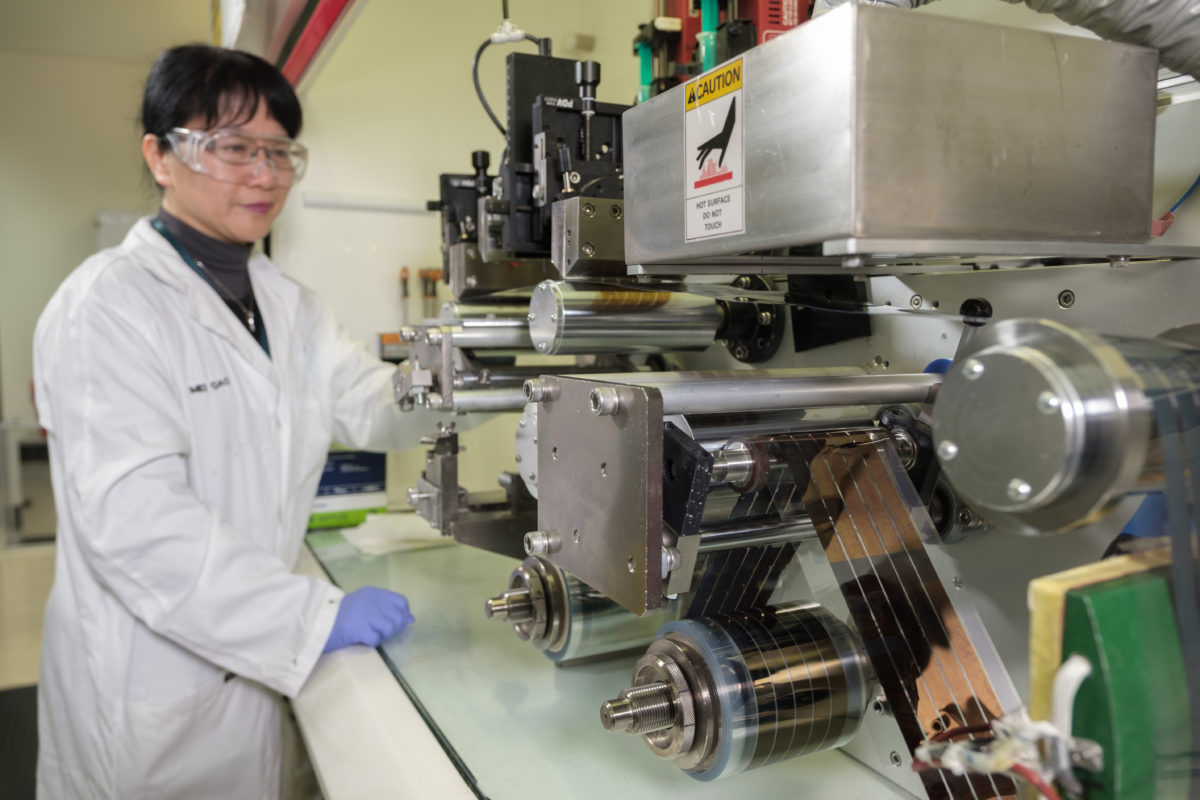

At Australia’s Commonwealth Scientific and Industrial Research Organization (CSIRO), the Printed Photovoltaics team is leading world-class research on flexible PSCs. The team is investigating scaling up flexible PSCs which are produced by vacuum-free methods. According to Mei Gao and Regine Chantler of CSIRO, flexible PSCs are light weight and potentially low cost. These properties could allow for broad application in areas such as BIPV, windows, facades, backpacks and clothing.

At CSIRO, PSCs are not prepared under clean room conditions, but under an environment suitable for large-scale industrial production, with a vision of commercializing flexible PSCs. Roll-to-roll technology is used for production, and lessons learned from organic solar cells are implemented into the design. Stability tests are also being performed on these flexible PSCs.

What is intriguing is that the flexible PSCs produced by CSIRO can also work under indoor light conditions. This opens up further opportunities such as being able to produce energy inside a building when the sun goes down.

Scaling up

Anita Ho-Baillie of University of Sydney leads a team focused on large area perovskite single junction and tandem solar cells with the aim of improving their prospects of commercialization. The idea is to demonstrate PSCs with areas larger than world record cells, which are often smaller than 0.1cm², and rarely larger than 1cm², and are not easily translatable, considering commercial solar cells and panels are much larger.

While many of the tandem demonstrations reported in literature make use of HJT silicon cells as the bottom cell, requiring most existing silicon cell manufacturers to re-tool to adopt those technologies, Ho-Baillie’s team focuses on the use of single-junction silicon cells, which dominate more than 90% of the current market. This makes her tandem technology highly transferrable. An example of Ho-Baillie’s work includes the demonstration of a 23% efficient monolithic perovskite/silicon tandem solar cell at 4cm², and a 22% efficient perovskite/silicon tandem at 16cm².

Additionally, the team has performed techno-economic analysis on this new technology, taking the uncertainty of cost inputs into consideration. The method is robust, having been used for costing perovskite on glass, roll-to-roll and commercial and emerging silicon solar cell technologies. Ho-Baillie added that from the cost analyses, cheaper alternatives need to be found to replace expensive laboratory-scale small-area deposition techniques, gold electrodes, and Spiro-OMeTAD for perovskite solar cells to be suitable for mass production.

When asked about cell stability testing, the holy grail for any perovskite solar cell, Ho-Baillie says she is optimistic about developing low-cost solutions for stabilizing cells with enough durability to pass the International Electrotechnical Commission (IEC) standard PV module tests. Tantalizingly, she reports that on this crucial topic there is more news to come.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

“An example of Ho-Baillie’s work includes the demonstration of a 23% efficient monolithic perovskite/silicon tandem solar cell at 4cm², and a 22% efficient perovskite/silicon tandem at 16cm².”

I’m still thinking the TOPCON solar cell technology might well be adaptable to a spray on process of perovskites to get that 30% to perhaps 35% solar PV tandem cell, which would be the product to use on buildings with larger than usual electric needs or homes with small roof spaces to implement solar PV on. This is so close, to the perfect storm. Getting long lasting tandem solar PV cells to break the 29% limit of mono-crystalline cells and having energy storage technology and R&D to increase energy density, while bringing down the price per kWh of energy storage can create the “actual” off grid system that meets or surpasses daily energy needs of the average citizen.

I have a house in Bulli NSW with a perfect north facing roof but I have no confidence in the people who sell solar panels. If a university on the other hand would like to use my roof I would pay for these new cells be installed.