Hydrogen Park South Australia (HyP SA) has not even finished commissioning its 1.25 MW electrolyser capable of producing 480 kilograms of green hydrogen a day, but today the project signed its first offtake agreement for excess production, with BOC, a supplier of compressed and bulk gases, chemicals and equipment across the South Pacific.

BOC, a subsidiary of Linde (global gas supply and engineering company) announced today that it will install a compressor at HyP SA’s Tonsley Innovation District site, to compress green hydrogen for transport by tube trailers to industrial customers in South Australia — which it used to serve from a brown-hydrogen-producing facility in Victoria — and ultimately to a new group of customers in Western Australia, the home of natural gas.

Image: BOC

Vesna Olles, Director of Strategy and Business Development at BOC, told pv magazine, “Interest in green hydrogen is growing considerably. Customers ask us, ‘How do we get to green hydrogen?’”

She says this agreement is particularly exciting because the offtake will also allow the first green hydrogen to be deployed in an industrial setting at BOC. That is, BOC’s Argon Purification Unit at Whyalla in South Australia, will use the hydrogen as an energy source to produce high-purity argon which is used in industrial processes and welding gases.

Hyp SA, is, a minimum-five-year, $11.4 million pilot project, developed by Australian Gas Networks (part of the Australian Gas Infrastructure Group (AGIG)), with a $4.9 million grant from the South Australian Government’s Renewable Technology Fund.

Piping a hydrogen blend to households

When fully commissioned at the end of 2020, it will begin supplying 5% renewable hydrogen into the natural gas network supplying 700 homes in the vicinity of the plant, a precursor to AGIG introducing 10% renewable hydrogen by 2030 into its Australia-wide network which provides more than 2 million customers with natural gas.

AGIG’s General Manager of People and Strategy, Craig de Laine, says the company periodically talks to its customers about their customer experience, their preferences and expectations, and 87% have said they expect AGIG to begin decarbonising their gas supplies.

Partly as a result of this feedback, AGIG is leading the Australian Hydrogen Centre Initiative, in partnership with the South Australian and Victorian Governments and other industry players. With ARENA funding, it is developing the technical feasibility plans and pilots it needs in order to safely transition to 100% hydrogen (or hydrogen plus biogas) in its network by 2050.

“We’ve got more than $9 billion invested in pipelines, distribution and storage infrastructure, so clearly this transition is very important for the long-term future of our business,” de Laine tells pv magazine.

On the road to a single renewable-energy system

De Laine is passionate on the topic, saying, “Hydrogen is the solar industry’s best friend, because we need renewable electricity and water to make green hydrogen, and that’s a substantial new industry and a substantial new market for the solar industry.”

Currently, HyP SA draws its H2O molecule-splitting energy from the South Australian grid during periods of high solar production and low energy demand; it will help even at this small scale to stabilise the grid when demand drops to unsustainable levels.

“I love thinking about people’s solar, installed on their homes, and using their excess solar, not just to make renewable electricity, but to make carbon-free gas,” says De Laine, “and about the way hydrogen brings the electricity and gas sectors together into a single renewable energy system.”

Image: Australian Gas Infrastructure Group

How many gigawatts of solar PV would turn the gas network green?

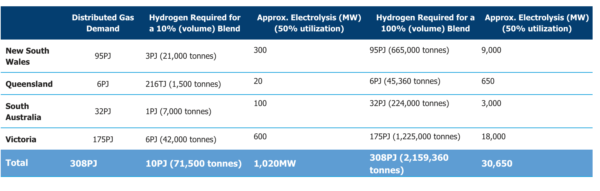

Of course, even supplying 10% of green hydrogen through the AGIG networks would require a gigawatt of solar capacity to power the electrolysers to produce the required 10 petajoules per annum; to go to 100% would require 30.6 GW of solar capacity to produce 308 petajoules. These figures conservatively assume running electrolysers 50% of the time to allow for variability in renewable-energy production.

Image: Australian Gas Infrastructure Group

BOC parent company Linde has its own commitments to decarbonise, with an interim target of 35% reduction in greenhouse emissions from 2017 levels by 2028, and a commitment to invest $1 billion in decarbonisation projects.

The contribution made by using and distributing green hydrogen from HyP SA is small in the Linde scheme of things, reducing distance traveled by BOC trucks by 117,000 kilometres each year to customers in SA, and thereby cutting emissions by 122,000 kilograms.

But it is demonstrating capability, as is the HyP SA project, to existing and potential customers in South Australia; and it’s expanding the market for green hydrogen into Western Australia.

Getting the egg rolling

“It can be a chicken-and-egg situation,” says Olles, speaking from the experience of BOC’s part in the H2OzBus Project to supply green-hydrogen to transport operators.

She says it started off as a push to drive interest in the Bulwer Island green hydrogen facility in Queensland, which will become operational in Q1 of 2021, “but now that transport operators know that we’re going to have a green hydrogen capability on Bulwer Island, we get a considerable amount of interest for the product — it opens an exciting avenue for new customers, and the ability to develop a foundation for hydrogen mobility in Australia.”

South Australia’s Minister for Energy and Mining, Dan Van Horst Pellekan, said of today’s HyP SA announcement, “This is an Australian-first application of tube trailers to transport renewable hydrogen to industry and will see the local production of green hydrogen to replace brown hydrogen currently imported from the east coast.”

Now HyP SA just needs to start producing green hydrogen to set off a whole new chain of opportunity, for carbon-free gas and the wind and solar resources that make it possible.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

2 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.