Australian mining technology company TNG Limited, which owns the world’s most advanced vanadium project, Mount Peake Vanadium-Titanium-Iron Project (Mount Peake Project), 230km north of Alice Springs in the Northern Territory (NT), has established a new Vanadium Redox Flow Battery (VRFB) business unit as the company looks to rapidly expand its green energy sector.

The Mount Peake Project is an enormous deposit of titanium dioxide pigment, iron ore fines products, and most importantly, high-purity vanadium pentoxide, one of the world’s great potential electrolytes as a key ingredient in VRFBs.

TNG’s new green-focused subsidiary, TNG Energy, has been established to develop its VRFBs for applications where it can help to reduce greenhouse emissions and provide an economic alternative to traditional sources of energy for off-grid sites, such as mines, farms, and remote indigenous communities, where it can work in tandem with wind and solar to provide a continuous source of renewable energy.

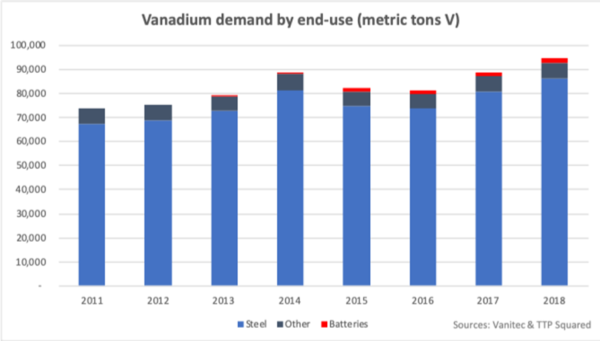

Of course, vanadium is most widely used as a steel strengthener, and indeed has been used as such for well over a century, the Ford Motor Company used vanadium steel to toughen up its Model T after Henry Ford observed European racing cars employing the mineral.

Recent years have seen the price of vanadium skyrocket, and this trend looks to continue due to the fact that the Chinese government have set high standards for the strength of steel in construction, seeing vanadium demand increase dramatically.

However, it is vanadium’s utility in energy storage which could prove a real game-changer, especially for off-grid solutions. “The VRFB market represents an exciting opportunity for the Company to further expand into the green energy sector,” said TNG’s managing director & CEO, Paul Burton, “and diversify the Mount Peake product portfolio with the future production of high-purity vanadium electrolyte.”

Energy Storage for remote sites

While VRFBs have a lower energy density than lithium-ion batteries, VRFBs can be easily scaled up to large sizes that can hold even more energy. This makes VRFBs ideal for remote off-grid sites because they can store up energy for several days if they’re big enough.

VRFBs are also hardy batteries, they can be shoved any old place and left to do their job for extended periods of time, requiring little maintenance. This is another plus when it comes to energy storage at, say, remote mine sites who are looking to disentangle themselves from diesel fuel by sourcing a modular solar solution.

There are few places as tough as an Outback pub, and that’s why the iconic Royal Mail Hotel in Meekatharra, Western Australia (WA), is in talks to add-on VRFBs to complement the pub’s recently installed rooftop solar array.

The pub and brothel patrons of the old days would also probably never have imagined that Meekatharra is home to the world’s largest undeveloped vanadium resource. Pub owner Gitte Heij has already been in touch with VSUN Energy, a subsidiary of Australian Vanadium Limited, about whether the Consortium can add some vanadium redox flow batteries as a route to true sustainability.

Image: Meekatharra Solar Consortium

“Having early dialogue with AVL and VSUN means we’re already looking ahead to the add-on potential of vanadium redox flow batteries and other energy innovations,” said Heij. Flow batteries would have a significant impact upon the project, giving its energy generation scalability, stability and better opportunity for energy trading and sharing.

Meekatharra is also home to a 455 kW hybrid solar array, the Meekatharra Solar Power Station, another system that could profit from a large low maintenance VRFB as the community looks to create a community trading platform.

VRFB as a hybrid solution

There is also great potential for VRFB as a hybridised solution with lithium-ion batteries. This is particularly apparent in the electric vehicle (EV) industry, as VRFBs are too large to be efficiently utilised in the space of an EV by itself.

However, as Victoria’s Monash University is demonstrating with the nation’s largest behind-the-meter hybrid battery storage system which combines a 180kW/900kWh vanadium redox flow battery system and a 120kW/120kWh C1-rated lithium-ion battery. As U.K. vanadium flow battery manufacturer RedT explained after it installed the system in 2018, the vanadium-flow “workhorse” provides around 80% of the energy and has the ability to store energy for more than four hours, while the lithium-ion batteries provide bursts of power for demand surges. The lithium-ion battery, supplied by Germany’s Tesvolt, uses Samsung cells. It can store energy for one to two hours and will be used for occasional bursts of short demand spikes.

As for TNG Energy, the subsidiary has already partnered with SMS group for the production of green hydrogen energy. Burton said: “The potential development of VRFBs using Mount Peake’s vanadium electrolyte, together with the recent agreement signed with SMS to develop a hydrogen production technology, marks another step towards realising our strategic vision of establishing TNG as a sustainable resources company and providing maximum benefit to our shareholders.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

7 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.