For Clive Fleming, getting development approval for his business, Reclaim PV Recycling, to set up Australia’s first large scale solar-panel recycling plant, and taking a long-term lease on an industrial property in Lonsdale, just outside Adelaide in South Australia, is a major milestone after years of research and logistical modelling in his efforts to stop broken or end-of-life solar panels going to landfill,.

With the facility site secured, Fleming is today kickstarting a nationwide collection network for his business by sending a callout to industry operators — solar suppliers, installers, maintenance operations — around Australia to nominate their business sites as recycling depots.

Participants need about 48 square metres of free space, and be willing to store up to three pallets of no longer useful solar panels. Around the three-pallet mark, Reclaim PV will organise pickup of the panels and transport them to Adelaide, in the first instance — Fleming is currently securing panel-processing sites in other states.

“Having a network of drop-off sites will significantly reduce the costs of transporting the panels to our warehouses and recycling facilities, compared to picking up 10 panels here, 15 panels there,” Fleming tells pv magazine Australia.

In 2015 Sustainability Victoria estimated that Australia’s installed solar infrastructure has a 15- to 35-year expected lifetime, so the waves of end-of-life panels are not expected to hit the dirt for another decade or so.

Disbelief seeds conviction

Recognising the enormity of the impending recycling task when as solar service providers they were told to dump 600 decommissioned panels from a site in 2011, Fleming and former business partner David Galloway started Reclaim PV .

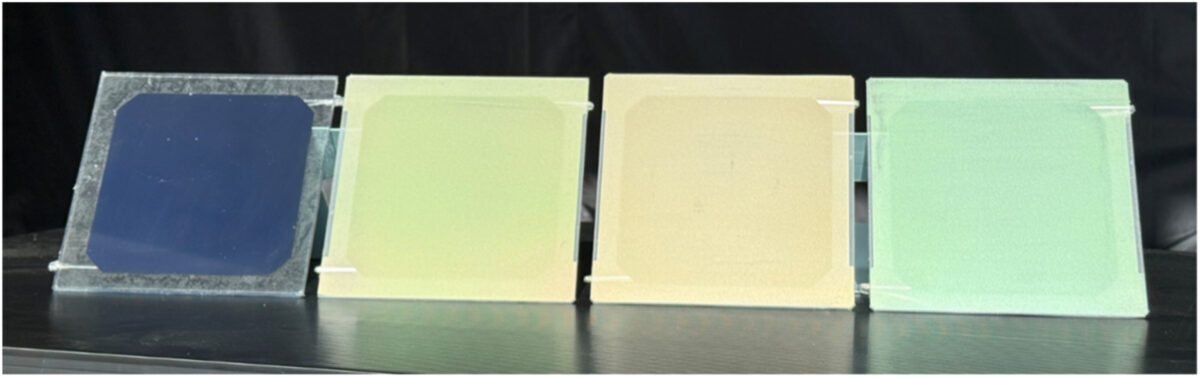

After pursuing grant-funded research into the best methods of separating the solar sandwich of materials bound together by adhesives such as ethyl vinyl acetate, the company developed a recycling process using pyrolysis — the staged application of heat in a furnace to peel away or melt the various components of the panels which are then recovered, sorted and sold to materials companies for reuse.

For the past few years Reclaim PV has been processing a test trickle of around 10,000 panels per annum, partnering with major manufacturers — such as Q Cells, Suntech, Canadian Solar, Yingli and Sunpower — which pay to recycle their solar panels that have failed under warranty or been damaged in transit; and collecting the detritus of decommissioning or freak events such as the hailstorms that battered parts of south east Queensland in November 2020.

Image: RACQ

The proportion of materials potentially recoverable from solar panels is typically glass (75%), aluminium (8%), silicon (5%), copper (1%) and smaller amounts of silver, tin, lead and other components.

A 2016 study jointly prepared by the International Renewable Energy Agency (IRENA) and the International Energy Agency (IEA) estimated that 78 million tonnes of raw materials with a combined value of US$15 billion could be recovered from solar panels globally by 2050.

The alternative is that solar waste left in landfill can leach materials, such as tin, lead and cadmium into groundwater, causing health and environmental concerns, never mind the inconceivable volume of lost opportunities and ground hogging.

Manufacturers with a conscience

Managing Director of Yingli Solar Australia, Tim Feng, tells pv magazine Australia that the company has installed some 100 MW of commercial rooftop and large-scale ground-mounted solar in Australia since it entered the market in 2012, which is when Fleming came to talk to them about the issue of stewardship and how the two entities could collaborate to ensure the integrity of the industry.

“As clean energy representatives,” Feng says that Yingli, “focuses on having the least impact on the environment during production, and once the product is sold, we focus on minimising the impact on that part as well.”

In mid 2020, in the absence of Federal policy to, say, impose a levy on solar panels, inverters and batteries imported into Australia and thereby help fund end-of-life recycling of solar waste, some Australian states began to take action. Victoria brought in a long-planned ban on the dumping of all e-waste, including solar panels, to landfill; and in August last year, NSW allocated a $10 million, two-stage grant funding scheme aimed at keeping end-of-life solar systems out of the ground we live on.

Known as the NSW Circular Solar Grants Program, the scheme was initiated in response to data that estimates NSW alone will generate between 3,000 and 10,000 tonnes of discarded solar panels by 2025, a volume that is forecast to grow to between 40,000 and 71,000 tonnes by 2035.

An industry-wide approach is needed

Fleming sees opportunity in the big numbers, which could make his business plan independent of government funding and fulfill his long-held vision for Reclaim PV to become the catalyst for a national system providing end-to-end recovery and recycling of solar panels in Australia.

He’s currently securing environmental licenses to conduct full-scale recycling in Lonsdale, at a startup rate of 70,000 a year, which is coincidentally the number of partly processed panels that he currently has in warehousing, just waiting for the company to hit full throttle.

Fleming is confident of future expansion, and continues to invite those involved in decommissioning solar, or companies replacing panels under warranty to contact Reclaim PV for pickup of their waste panels; while simultaneously calling on industry to live the dream and become part of Reclaim PV’s network of drop-off points for discarded solar panels.

The more sites that nominate themselves as panel pickup points around Australia, the more convenient the network will become to “un-installers” and electricians called on to disconnect and dispose of damaged or faulty panels.

The more industry participates in a distributed depot system, less it costs Reclaim PV to transport the panels, the more competitive it can afford to be with fees charged by councils to accept solar panels as landfill, or process them as electronic waste.

“I’m appealing to these businesses that are handling solar panels, that have a little bit of extra space,” he says. “If we can do this as an industry, it will drop the cost of transport, and our recycling service, and we can all feel good about it.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Thank you for sending me the information about it. I learned from it. I appreciate the detail you went into it. I am grateful for the amount of time and effort you put into this helping us. Your insights and summary are beneficial.