From pv magazine Global.

Electric cars are pretty heavy and, therefore, need quite a bit of energy to move. The culprit, is the battery. But what if the chassis itself was rechargeable, rather than a battery added to the structure?

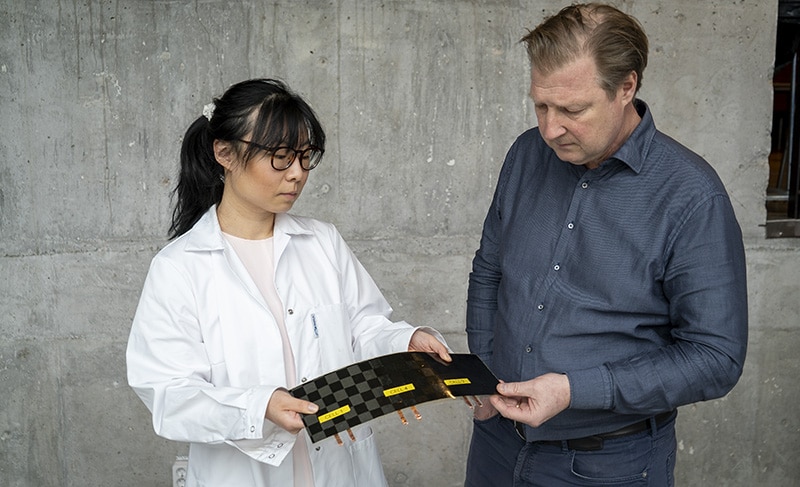

Researchers from the Chalmers University of Technology in Gothenburg, and the KTH Royal Institute of Technology in Stockholm claim to have taken a significant stride towards making that vision a reality. The ‘massless’ batteries envisioned–so called because their weight is not added on top of a vehicle structure–have been the subject of research since 2007. The Swedish researchers say their discovery has improved such devices by a factor of ten.

Their battery features a carbon fibre negative electrode and a positive electrode made from lithium-ion-phosphate-coated aluminium foil. A fibreglass fabric separates the components which are then woven, like ordinary carbon fibre, and surrounded by an electrolyte matrix. The matrix consisted of a porous methacrylate polymer which the researchers impregnated with a liquid electrolyte of lithium salts, for high ionic conductivity.

Serendipity

The team has said their eureka! moment arrived through happy accident. Initially, the group had attempted to investigate the structural effects of separator thickness only to discover their approach resulted in a battery ten times better than other ‘structural’–or ‘massless’–batteries. With an energy density of 24 Wh/kg, their structural battery has just 20% of the figure boasted by conventional lithium-ion batteries. However, because the weight of a vehicle using such devices would be significantly reduced, that is of no great concern, the researchers said.

To illustrate the point, the Swedish team pointed out the 85 kWh battery in a Tesla Model S makes up around a quarter of the vehicle’s weight. Plus, with massless batteries storing lower energy than conventional devices, they also comprise less of a safety risk.

In flexibility terms, the device was tested for an elastic modulus of 25 gigapascals and tensile strength exceeding 300 megapascals, and can thus compete with common construction materials, according to the researchers. “Previous attempts to make structural batteries have resulted in cells with either good mechanical properties or good electrical properties,” said Leif Asp, professor at Chalmers and leader of the project. “But here, using carbon fibre, we have succeeded in designing a structural battery with both competitive energy storage capacity and rigidity.”

With their results having been achieved by accident, the academics believe there is room for improvement. Asp suggested an energy density of around 75 Wh/kg and a stiffness of 75 gigapascals could be within reach. Electrochemical performance is limited by the mass of active materials relative to total mass. That means achieving a higher proportion of fibres to electrolyte would improve battery performance and a more refined industrial manufacturing process could improve the fibre-to-electrolyte ratio drastically.

In terms of cycling stability, the researchers have claimed their device showed no significant capacity degradation signs after 60 cycles.

“The next-generation structural battery has fantastic potential,” said Asp. “If you look at consumer technology, it could be quite possible, within a few years, to manufacture smartphones, laptops or electric bicycles that weigh half as much as today and are much more compact.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.