From pv magazine Global

Scientists at Germany’s Karlsruhe Institute of Technology (KIT) claim to have achieved an efficiency of 18% for a perovskite solar module with an area of 4cm2 – a world record for a vacuum-processed perovskite panel.

The researchers explained they were able to scale up from the cell to the module level without any efficiency loss, which they described as the main challenge for the development of large-area perovskite PV modules.

The perovskite cells were connected in series to form large-area solar modules using the so-called monolithic series connection, with structuring lines being introduced during the deposition of a cell’s individual layers, which were all deposited through a vacuum process.

“The major advantages of vacuum deposition with regard to the production of efficient solar modules, are the ease with which the processes can be controlled, the low number of process parameters and, in particular, the independence of the deposition mechanism from the coating surface,” said KIT researcher Tobias Abzieher, noting that the process was used in combination with a laser technique for the monolithic series connection.

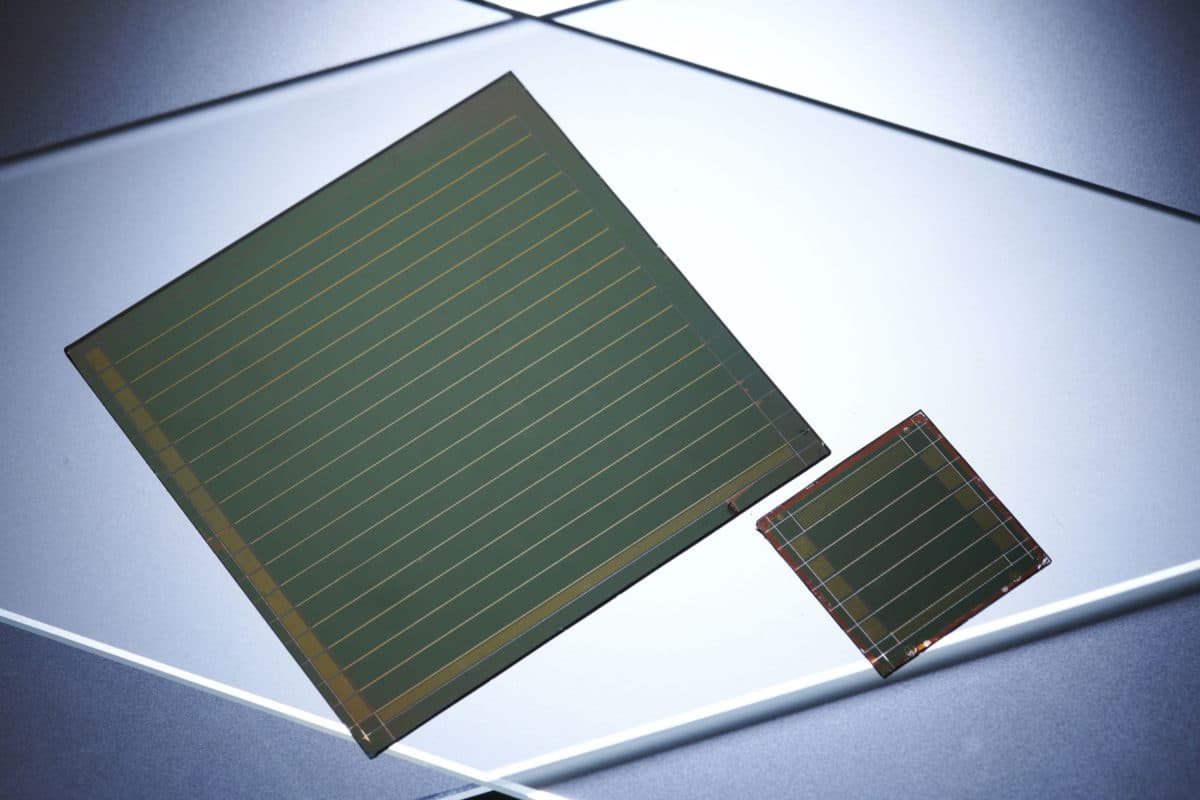

With the combination of vacuum processing and laser ablation, the scientists achieved an efficiency of up to 16.6% on a module surface of more than 50cm2 and 18% on a module with an area of 4cm2. “Despite the enlargement of the device’s area by a factor of over 500, almost no loss of efficiency can be observed,” said researcher David Ritzer.

With its approach, KIT claims to have succeeded in reducing the scaling losses in perovskite solar modules to values that are close to those of cadmium telluride (CdTe) or copper-indium-gallium-diselenide (CIGS) modules.

In the future, the researchers will work on optimising the solar cell layer stack and on further reducing the dead areas. “If we fully exploit the potential of the technology, the production of perovskite solar modules with efficiencies of well over 20%, even on even larger areas, is an achievable goal in a timely manner,” said researcher Ulrich Paetzold.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.