“This is a scientific paper rather than a new-product release,” cautions Nichols Ekins-Daukes, emphasising the theoretical win documented in a new paper he co-authored on the discovered effects of adding a layer of singlet-fission material such as tetracene to silicon solar cells.

The benefits are two-fold, in that the tetracene layer doubles the number of electrons produced by each photon in photovoltaics, from one to two. That is, “a photo-excited singlet exciton undergoes fission into two triplet excitons, producing twice the electronic charge carriers for each absorbed photon,” explains the paper.

This increases the efficiency or output of energy converted from sunlight by the solar cell — although it doesn’t necessarily double it.

“In terms of our study, we’ve got our solar cell operating at 32%,” Ekins-Daukes tells pv magazine Australia, “which is substantially higher than baseline solar at 26%.”

He points out that some of the study’s co-authors have previously made calculations on the absolute efficiency achievable with singlet fission — ”and that takes you to 45.9%, so in principle the concept can lead to really high gains”.

The second benefit, which the authors say is often overlooked in the race to increase everyday efficiency of solar conversion, is the module-life extension bestowed by this process, because it lowers the operating temperature of the silicon cells.

Solar cells as fridge magnets

Professor Martin Green of the School of Photovoltaic and Renewable Energy Engineering at UNSW, a co-author of this paper, has often been heard to say that solar modules would prefer to be operating in a fridge, and yet their working environment can see them reach temperatures of 50 degrees Celsius.

The single-fission process using tetracene in particular, compared to other possible singlet fission materials, is endothermic; in this investigation it was found to reduce the operating temperature of the solar cell by 2.4 degrees Celsius.

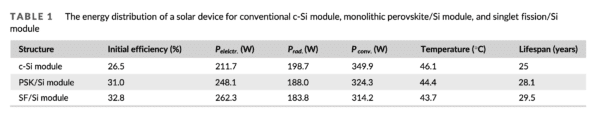

Given that every 10-degree reduction in operating temperature over time can double the lifespan of solar cells, the authors calculated that the reduction brought about by singlet fission would add 4.5 years to today’s typical high-performance panels, bringing the theoretical warrantable period up from current 25 years to 29.5 years and delivering substantially more electricity over their lifetime.

A bonus delivered by tetracene is that although it degrades over time, its degradation makes it transparent to sunlight. Explains Ekins-Daukes: “Initially the solar cell would be more efficient, then if that singlet fission material degrades, it gets out of the way, so the solar cell efficiency will drop, but only to the performance level you’d expect of a baseline silicon cell.”

Overcoming instability in perovskites and singlet fission materials

The paper, titled Singlet fission and tandem solar cells reduce thermal degradation and enhance lifespan, actually compared the performance gains of two types of tandem solar cell — those layered with perovskite material and those topped with tetracene. Table 1 shows the differences in performance, with singlet fission using tetracene to be a clear winner.

Tandem approaches are at various stages of development, and “All have a question mark next to them,” says Ekins-Daukes.

He adds that some technologies have so far received more investment and attention than others, but “The opportunity here is that the molecular single-fission layer in principle is just an add-on to the manufacturing of photovoltaic devices.”

Via this study, tetracene has become a useful prototype, even though it may not be the material eventually used should the technology go into production.

ARC Centres of Excellence, where schools of thought meet

The origins of the study stem from an interdisciplinary approach enabled by the ARC Centre for Excellence in Exciton Science, of which UNSW SPREE and the School of Chemistry at UNSW are participants.

“The ARC Centre is funded to study the fundamental processes, such as are going on in this material,” says Ekins-Daukes.

SPREE typically works closely with industry to improve efficiency of near-term manufacturable devices. Professor Green’s recent wide-ranging desktop study on a variety of module-cooling mechanisms including vortex generators is an example of the group’s extremely successful, industry-integrated approach.

“But this was an opportunity where we could partner with our colleagues in the Science School and take a piece of science that is in its early stage, demonstrating the single-fission mechanism and some of the candidate materials,” says Ekins-Daukes.

Another co-author on the project, Murad Tayebjee, also with SPREE, is working to find alternatives to tetracene that may be receptive to more of the solar spectrum, or that are more stable than tetracene over time.

In the meantime, the tetracene study has shown the necessary effects, says Ekins-Daukes, “and provides us with the opportunity to push the concept forward, while finding suitable alternative materials.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.