Organisations the world over are committing to net zero carbon emissions, and have understood and in many cases captured the low-hanging fruit of greening their electricity supply. But the road to green thermal adoption — or the decarbonisation of heat processes — requires business plans that anticipate maturing green technologies and build in the flexibility to switch as those technologies become available and commercially attractive. Influential factors might include when the cost of electricity generated by expanding solar and wind installation is consistently close to zero, or markets putting a price on carbon…

Engie Impact, the strategic and engineering advisory arm of French energy giant Engie, has, for example, been working with a client that produces chemical and consumer goods, using processes that require temperatures of about 250 degrees Celsius.

“It’s a mid-temperature application,” explains Josh Martin, Senior Director of Engie Impact Australia , “and they were looking to invest in a more efficient gas heating solution, but they also wanted a deeper analysis of the green solutions, which include biomass boilers, biomethane boilers or green electric heaters.”

On a strictly financial basis, Engie Impact found the cost of switching to a green thermal supply would be 18% higher than gas boilers, “but once we accounted for a carbon price, the business case became more favourable”, Martin tells pv magazine Australia. In fact, electric heaters powered by renewable energy sources were found to offer the lowest total cost when the carbon price was considered, and significantly reduced the company’s greenhouse gas emissions over the asset lifetime.

Engie Impact exists solely to accelerate decarbonisation. It started Australian operations early this year with a staff of nine, and is now building additional teams of five in both Sydney and Perth to meet demand.

Martin says, “It’s good to see that organisations are taking this seriously; probably the most humbling thing to me is that we’re seeing a lot of action.”

Feeling the fossil fuelled heat

That said, a global assessment by Engie Impact of companies with science-based emissions-reduction targets found that although 65% have made significant strides in procuring renewable sources of electricity, ”only 27% have done the same for heat”.

For low-temperature heat requirements, such as space heating of buildings, available technologies such as solar collectors and heat pumps are not being leveraged in any significant quantities, says Martin, who adds, “I think it’s likely because there’s a lack of knowledge around them — on the electricity side, everyone knows about LED lights, but the average person wouldn’t be able to explain the concepts behind a heat pump.”

Industrial heat demand, however, is forecast by the International Energy Agency to continue to grow, and is expected to account for “a quarter of global emissions by 2040”.

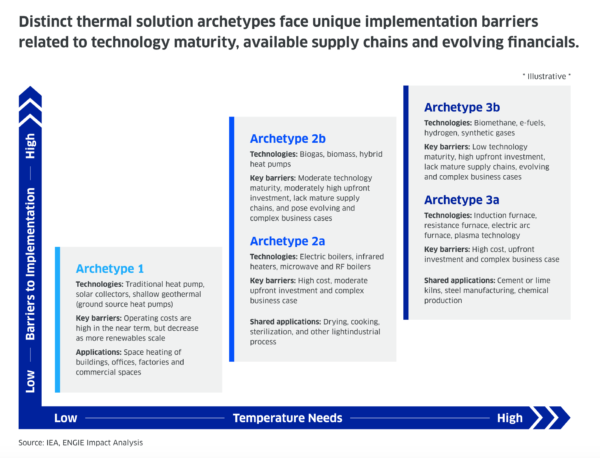

The challenges of transitioning heat processes are complex because, unlike fairly generic requirements of heating residential and commercial buildings, industrial heat processes require a range of temperature levels for different processes and end uses, and the heat is often generated on site by assets that have a lifespan of up to 40 years.

As in the chemical and consumer-goods example, there may be a case for switching out the existing technology sooner than its projected end of life, but that depends on a number of factors, including energy-market conditions, consumer demand, net-zero targets of countries and individual corporations, and the value that organisations place on producing greener goods or just running cleaner.

Complexity in individual industries such as steel production, is compounded by the fact that some technologies, such as replacing coking coal with green hydrogen in the steel manufacturing process are still being trialled. Other technologies, such as electric arc furnaces are proven and available, but only account for part of the steel manufacturing process and only reduce emissions by 50% over coal or gas-fired blast furnaces.

It’s time to scale

Martin believes that the time for trialling technologies to replace fossil-fuelled heat processes is limited, and that investment in the most promising technologies should be scaled up now in order to meet decarbonisation goals.

At the same time, he says, organisations need to plan their exit from reliance on fossil fuels to generate heat: “It’s about understanding what the solutions are, investing in developing those technologies in terms of R&D and supply chains, and having industry ready to switch, with a smooth transition to green solutions as they emerge, and as current technologies come to their end of life.”

The availability of investment capital and policy settings that incentivise transition are essential, he says.

An Engie Impact global publication, Green Thermal: How to Build Roadmaps to Decarbonise Heat, offers four strategies for policymakers:

- Significantly increase penalties to carbon-emitting companies

- Incentivise R&D investments in green thermal technologies

- Facilitate the acceleration of green-thermal markets (offtake contracts could work in a similar way to power purchase agreements that have supported the development of renewable power projects)

- Commit to deployment of large-scale hydrogen infrastructure.

Its recommendations for organisations are necessarily complex but clear:

-

- Assess the long-term cost outlook of technologies. In brief, Engie Impact’s advisors write, “With a strong and integrated understanding of cost dynamics, organisations evaluating emerging fuels can be far more precise in developing their least cost pathways to decarbonisation.” They caution that the market has been reliably wrong in assessing the future cost of renewables — in other words, like low-cost solar PV, viable alternatives will be upon us more quickly than we might expect.

- Explore alternative revenue streams and synergies. Look for opportunities to share resources and the costs of development. For example, Engie Impact suggests partnering with neighbouring companies that may produce methanol or biomass that could be utilised in heat generation technologies.

- Plan to adapt with dual-asset strategies. Avoid investing in assets that will lock in emissions for decades to come. Instead, look for flexible technologies such as dual-fuel generation that can be adapted as green-fuel sources become more widely and cost-effectively available — natural gas-fired plant that can adapt to hydrogen is one example.

- Build organisational accountability for emissions reduction and understanding of the options.

Martin also cautions against spending corporate funds on carbon offsets that could better be spent on developing pathways for integration of green-energy heat processes: “You obviously don’t want to be diverting funds away from technological solutions that offer permanent displacement of carbon emissions,” he says.

Engie Impact works with its clients on identifying tailored pathways to decarbonisation, and the business cases for deploying various solutions; the next step can be to partner with the organisation on research and development of the solution, with the aim of demonstrating that it can work at commercial scale.

Engie Impact’s parent company Engie, for example, recently partnered with Yara Pilbara Fertilisers to show the feasibility of transitioning Yara’s ammonia plant from using natural gas in its heat-reliant processes, to using green hydrogen.

The project progressed in May this year when it was awarded $42.5 million in funding from the Australian Renewable Energy Agency (ARENA) to develop a 10 MW onsite solar farm and electrolyser that will directly supply the plant with renewable hydrogen, ultimately producing green ammonia for the Australian market and for export.

Trail-blazing software can help decision making

In September, Engie Impact also celebrated the global launch of its Ellipse carbon-intelligence platform, which Martin says goes a step further than current tools which typically digest data and report on emissions levels.

Rather, it “leverages machine learning and AI to help companies establish decarbonisation pathways and track those pathways”, he explains.

Using the platform does require some expertise to ensure it is fed the most accurate and best-available data, so that managers can confidently interpret the outputs for decision making. That expertise may be available within an organisation, or Engie Impact’s advisory team can assist, says Martin.

However companies go about it, decarbonising heat processes needs to be thought through, says Martin: “You have to be able to demonstrate to investors that you’ve optimised your solutions for the right technologies at the least cost.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

3 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.