Researchers at The University of Queensland (UQ) have declared advances in nanomaterial technology have allowed them to manufacture perovskite-based solar cells that are as efficient as conventional silicon-based cells, but without the high costs and complex manufacturing processes.

While silicon-based solar cells continue to dominate the market, perovskite solar cells have attracted enormous attention because of their high-efficiency potential and low-cost production but the technology still has some drawbacks including poor long-term stability.

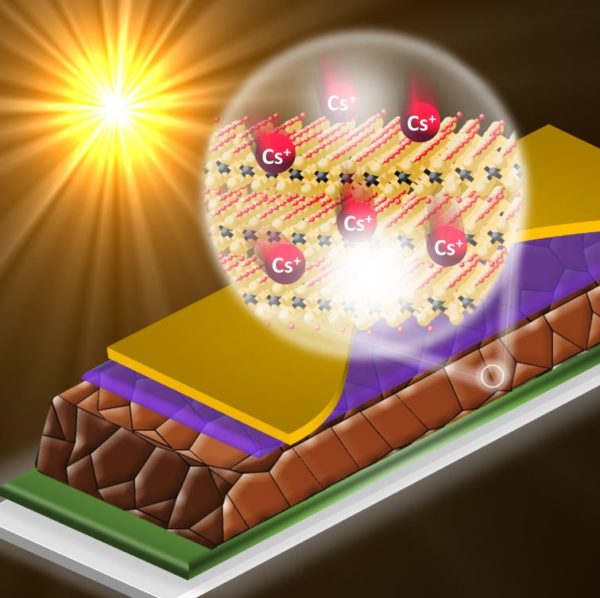

The UQ research team, based at the Australian Institute for Bioengineering and Nanotechnology, have used titanium carbide nanosheets doped with cesium (Cs) to fabricate perovskite solar cells which they claim deliver a PV efficiency of up to 21.57% with “excellent thermal stability”.

“Our theoretical and experimental analysis reveal that cesium plays an important role in improving perovskite crystallization and thus leads to enlarged crystal grains, long-lived carrier lifetimes, and reduced charge recombination,” the academics said.

Research team leader Professor Joe Shapter said the results, published in the journal Cell Reports Physical Science, show that the efficiency and thermal stability of the doped cells significantly outperformed those that were not doped.

“The PSCs that had doped cells showed a remarkable solar conversion efficiency that exceeded 21%,” he said.

“This gives us hope that solar energy can continue to develop and improve as one of the most effective renewable and sustainable energy technologies.”

Image: UQ

Shapter said the research, which involved scientists from École polytechnique fédérale de Lausanne in Switzerland and Griffith University in Queensland, addresses an urgent need for alternative energy sources capable of providing efficient and reliable energy production.

“Silicon-based solar cells remain the dominant first-generation product making up 90% of the market, but demand was high for cells that could be manufactured without their high prices and complexity,” he said.

“Our research contributes to intensive efforts to develop various types of solar cells with the aim of realising efficient, stable and low-cost replacements for present silicon-based technology.”

The findings come with solar module manufacturing giants LONGi Green Energy, JinkoSolar, Trina Solar, JA Solar and Risen Energy warning that rising material costs – including the price of polysilicon which is used in an estimated 98% of solar PV cells – could trigger a solar panel shortage.

In an open letter published earlier this week, the Chinese-based manufacturers said their output is expected to be reduced as rising costs, an ongoing shipping “crisis” and government-imposed restrictions take a toll on the supply chain.

The Chinese government has ordered silicon metal refineries in the country to cut output to about 70% amid a power crisis.

Daqo New Energy

“The raw material supply gap is serious,” the companies said in the statement.

“This imbalance will break the supply chain and seriously endanger the healthy and sustainable development of the industry.

“Prices are also soaring.”

The manufacturers said the price of solar-grade polysilicon has surged in recent weeks by 9.1% while the price of solar glass has also climbed, up 18.2% year-on-year and there has been a 35% increase in the cost of adhesive films used in the manufacture of modules.

The manufacturers said the capacity shortage will make it difficult for customers to meet installation targets, warning that many signed orders will be lost.

“The … industry has been caught in a difficult situation,” they said.

The companies said they are actively coordinating resources and making every effort to “stabilize supply” but implored customers to considering postponing projects and to avoid the end-of-year “rush to install”.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.