From pv magazine 11/2021

To storage system operators, the math is simple. A battery asset calculated over 10 years needs to perform as planned, or the investment is at risk. From an environmental perspective, battery performance also counts. They can only yield a positive contribution to our zero-carbon goals if they offset their production emissions over their lifetime. But regardless of your viewpoint, battery enthusiasts of all walks have had a hard time reading the news lately. With the fast growth of the battery industry, the number of battery incidents has also increased.

A prominent example is the 2019 fire at an APS site in McMicken, Arizona. A battery failure led to a massive explosion in one of the storage containers, causing millions in damages and hospitalising several firefighters. In the automotive world, General Motors, Hyundai, and Kia had to recall over 200,000 EVs after more than 30 battery fires between 2020 and 2021. And in the second half of 2021, Tesla Energy experienced two major setbacks. First, two battery containers at their Victorian “Big Battery” caught fire during commissioning. Two months later, the Australian Energy Regulator announced that it was suing Neoen SA, the operator of Tesla’s grid-scale batteries in South Australia, because of alleged systematic underperformance at its 129 MWh Hornsdale site. But are these examples representative for a whole industry?

To dig into the reality of battery performance and safety, I’m pleased to introduce the extensive battery performance database of Accure Battery Intelligence. Accure manages millions of battery cells around the world and strives to make them safe and reliable using cloud computing mixed with domain-specific expertise. For the following analysis, we focus on lithium-ion batteries used in stationary applications. All results are anonymised for confidentiality reasons.

Battery health

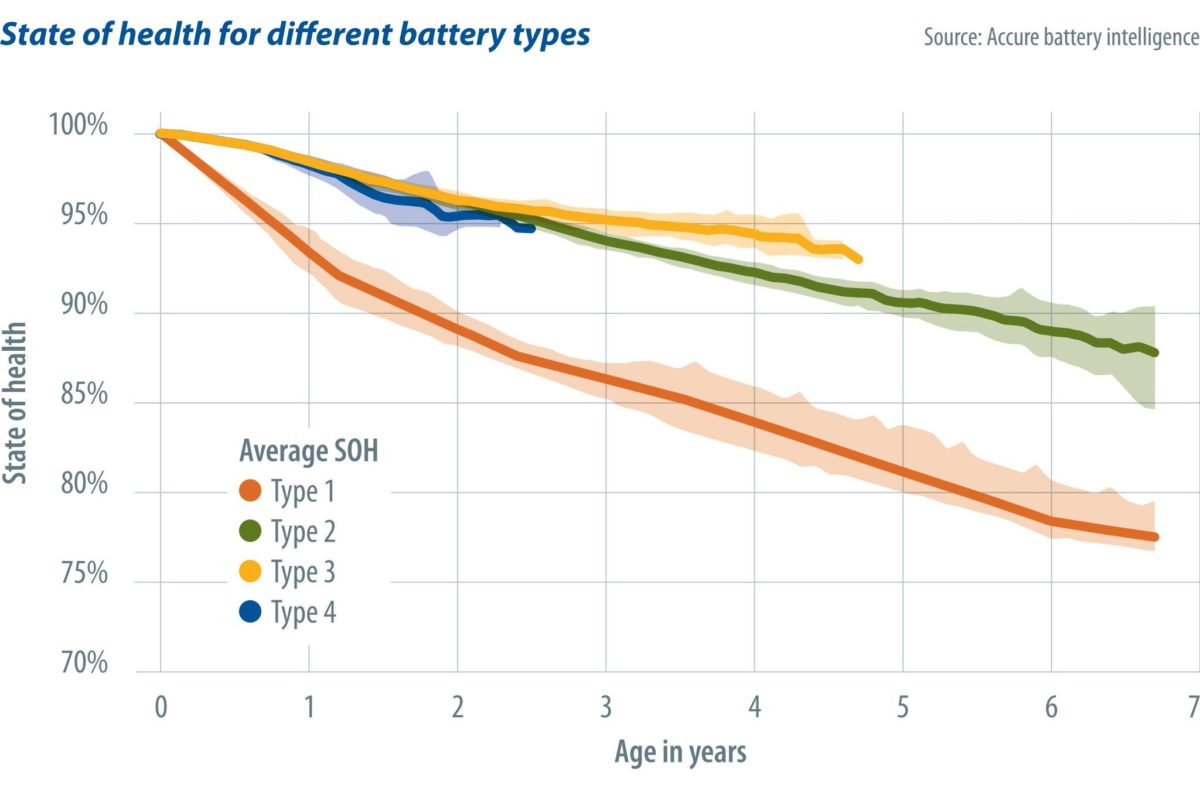

The chart on the bottom-left shows the development of the state of health (SOH) of different battery types. For a 10 kWh battery 92% SOH means a remaining usable capacity of 9.2 kWh. The end of life for lithium-ion batteries is usually defined as the point when the remaining capacity reaches 60% to 70% of its original value. After that, degradation accelerates exponentially so that the system is shut down permanently.

Starting with the good news, there are some excellent batteries on the market that have shown top performance for years. Batteries of type three show an average capacity loss of about one percentage point per year. Based on physical-chemical modelling and AI-based methods we can predict that these batteries will likely exceed a lifetime of 15 years. However, there are other examples as well. Batteries of type one show a much quicker ageing although their operating conditions and load profile are comparable.

In a broader perspective, we saw two interesting things:

- Many battery operators were not aware that their assets were underperforming (whether in health, efficiency or state estimation) and losing money as a consequence.

- By analysing the reasons for battery degradation and adjusting the energy management system accordingly, the lifetime could be extended by 20% to 25% in many cases.

Cell safety

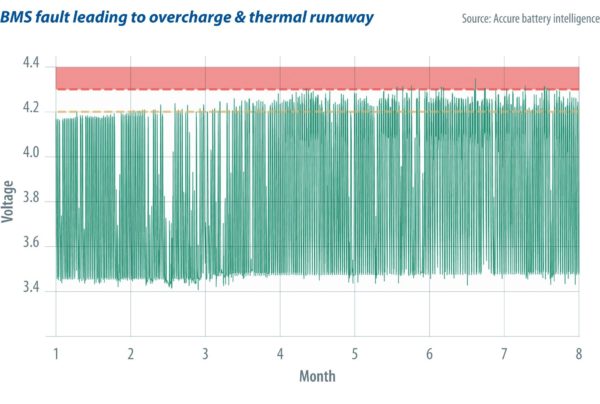

While batteries are usually designed for 10 to 20 years of lifetime, they can go up in flames in a matter of seconds. The root cause of battery fires usually lies in production errors or inappropriate operation. One example of the latter can be seen in the chart (below), where the battery management system (BMS) pushes the battery into a regular overcharge, which dramatically increases ageing and can even lead to a thermal runaway. It is crystal clear that a well-designed BMS should never allow such a behaviour. But this is the real-world where things don’t always go as expected and, in this case, it did. Thankfully, in this particular instance a secondary monitoring layer was active, so a thermal event could be avoided.

Battery performance and safety are puzzles with many pieces – from manufacturing quality to system design to operation and monitoring. While comprehensive monitoring solutions have long been standard for wind and solar installations of all sizes, the market is still inexperienced when it comes to batteries, even though the potential damages are much higher. As battery deployments grow exponentially, scalable solutions will be needed to ensure safety and optimal usage. Data-driven solutions look into the “black box” of battery performance and can make life easier for system integrators and operators, but also risk takers. Based on a continuous monitoring, innovative insurance products for battery assets have entered the market, among others provided by Accure and HDI Th!nx.

Author: Kai-Philipp Kairies

About the author

Kai-Philipp Kairies is a scientist and entrepreneur focusing on innovative storage solutions. He has worked as a battery researcher and consultant in Germany, Singapore, and California. Since 2020, he has been the CEO of ACCURE Battery Intelligence, a startup that supports companies in understanding and improving battery safety and longevity using advanced data analytics.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

In the end, this article tells us little. It does not identify the type, (Li-Ion, AGM, LFP, Lead Acid or Potato battery), of batteries performed how in this study.