Sydney-based solar startup SunDrive, which created the most efficient commercial-sized silicon solar cell in the world in September, has taken to social media to announce its latest feat – the successful fabrication of its first full-size solar panel.

From a garage in Sydney’s south, SunDrive’s chief executive started the company with former flatmate David Hu in 2015 based on a solution developed while completing his PhD at the University of New South Wales (UNSW), adding another chapter to UNSW’s storied solar history.

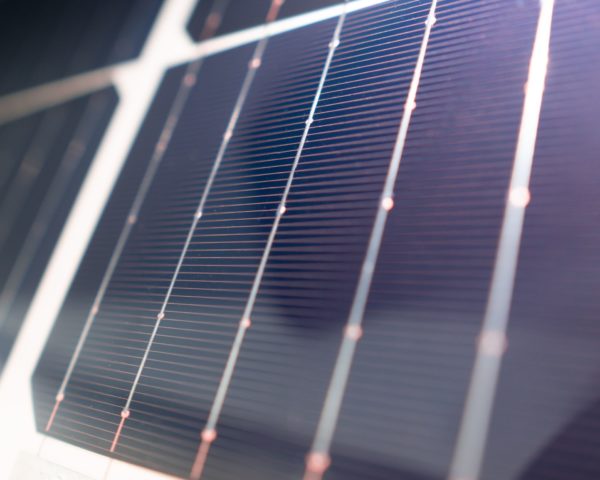

The solution, reached by hundreds of experiments in trial and error, amounts to a major shakeup of the solar industry’s Chinese cell manufacturing supremacy, replaces traditional and expensive silver use in solar cells with the much more abundant and much cheaper copper. Copper is not as conductive as silver, nor as adhesive to the solar cell, but Allen’s solution rectifies this disparity as evidenced by its 25.54 world efficiency record confirmed by the German Institute for Solar Energy Research (ISFH).

This week’s announcement that SunDrive has successfully fabricated its first full-size panel is another major milestone on the company’s journey from photovoltaic breakthrough to commercial success.

“From our process engineers interconnecting every cell to our build team designing the tools to make all this possible, everyone has put in immense effort to making this a reality,” the company said in a post on LinkedIn. “We are now gearing up to fully automate our technology as we continue to grow our world class team.”

The big “If” of SunDrive has always been whether it can mass produce its technology. If so, the Aussie startup could usher in the next great solar panel cost reduction while also lessening the industry’s dependence on silver, a precious metal of rapidly increasing price.

Silver is central to today’s solar panels. It is estimated solar panel manufacturing accounts for approximately 20% of the world’s annual consumption, a figure which is only going to increase thanks to the next generation of high-efficiency cells which can require up to three times more silver than previous generations.

Allen has previously said SunDrive’s aim is to produce the cells locally, optimistic that they can compete with large solar manufacturers in Asia while protecting their intellectual property.

“The industry today is at a point where the land and labour costs are becoming less and less significant in the total cost of manufacturing … obviously it does mean that we need to at least match that similar level of automation and throughput, but we do see opportunity to do it in Australia,” he said.

On top of more than $2 million in grants from the Australian Renewable Energy Agency (ARENA), SunDrive has already attracted high-profile investors, including Australian billionaire Mike Cannon-Brookes’s Grok Ventures.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

14 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.