From pv magazine Global | via the Hydrogen Stream

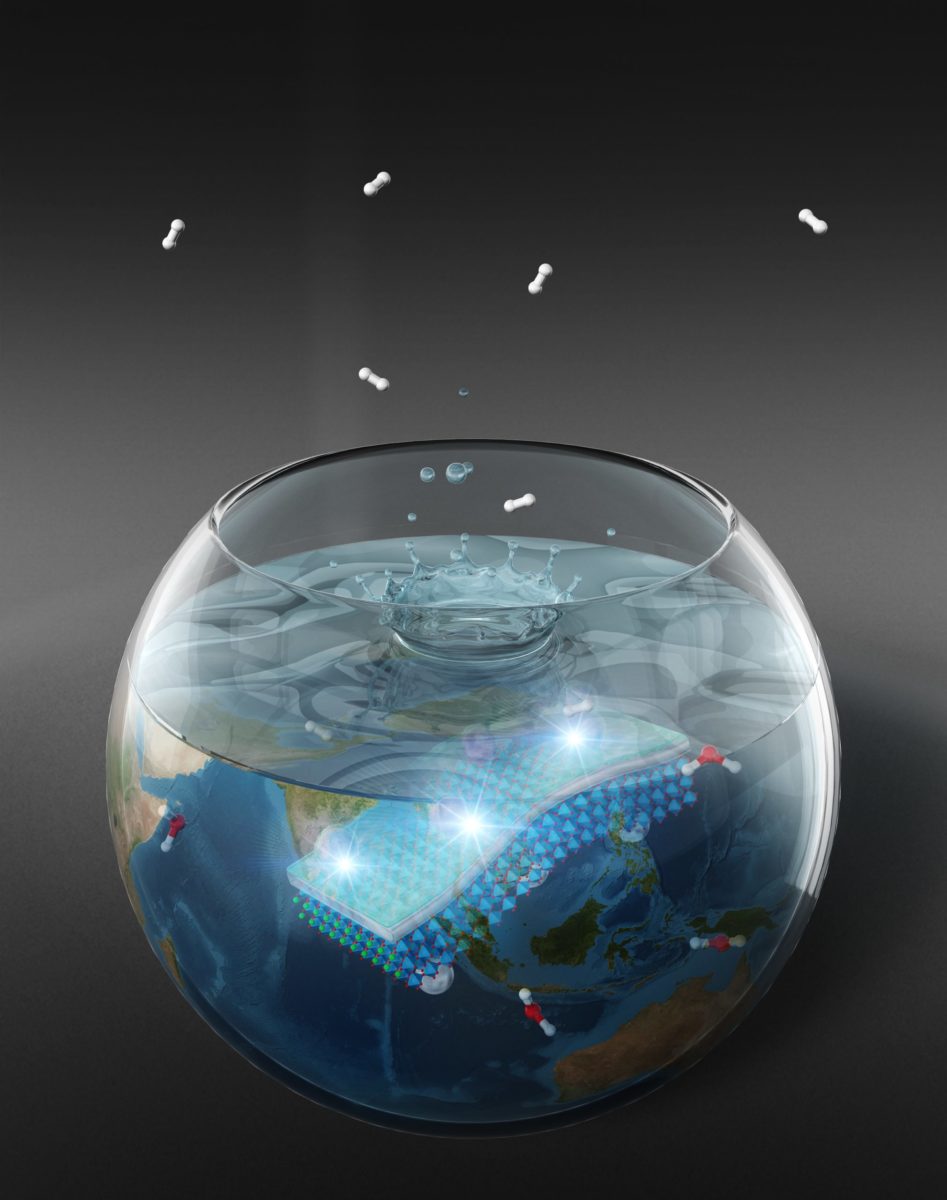

Tokyo Institute of Technology researchers have optimised a dye-sensitised photocatalyst, reportedly improving water-splitting activity up to 100 times. The team, led by Assistant Professor Shunta Nishioka and Professor Kazuhiko Maeda, used ruthenium (Ru) dye-sensitised niobate nanosheets (Ru/Pt/HCa2Nb3O10) to suppress undesirable back electron transfer. The water-splitting system also consists of an oxygen evolution photocatalyst. Maeda said that the surface modification makes the nanosheet photocatalyst comparable to conventional semiconductor-based photocatalyst systems. “With the back electron transfer suppressed, the developed photocatalyst could also maintain hydrogen production at low light levels, giving it an edge over other photocatalysts that require high light intensities,” the researchers wrote in “Surface-Modified, Dye-Sensitised Niobate Nanosheets Enabling an Efficient Solar-Driven Z-Scheme for Overall Water Splitting.” Photocatalysts can absorb light and carry out water-splitting reactions simultaneously, generating an electron-hole pair for the water-splitting reaction. Researchers have previously developed a photocatalytic system, involving two semiconductor materials and an electron mediator, to prevent charge carriers from recombining. However, this development led to the undesired back electron transfer. “The electron mediator, which is typically a reversible electron acceptor/donor pairs, accepts electrons from one of the photocatalysts and donates them to the other,” the researchers wrote in Science Advances. They optimised the photocatalyst to avoid having the electron-accepting species compete with the hydrogen photocatalyst for electrons, which normally results in poor solar-to-hydrogen energy conversion efficiencies.

South Korea has completed its largest hydrogen production complex in the city of Pyeongtaek, Gyeonggi province. The US$17.5 million (AU$25 million) facility will produce up to 7 tons of hydrogen per day, or 2,450 tons a year, by pyrolysing gas via steam. It will annually supply fuel for up to 410,000 hydrogen vehicles. On average, most of the 33 hydrogen refuelling stations operating in the Seoul region have been supplied with hydrogen from more than 120 kilometres away. “As the completion of this complex stands to substantially reduce hydrogen transportation costs, the provincial government expects the hydrogen supply price in the Korean capital region to drop as well,” said the authorities.

ScotWind has cleared the process to offer seabed agreements for three new offshore wind projects. “The three projects’ initial supply chain commitments indicate an average of GBP 1.2 billion (AU$2 billion) investment in Scotland per gigawatt of capacity built,” wrote Crown Estate Scotland. The three projects cover 560 square kilometres of the seabed and are expected to generate 2.8 GW of electricity. “The Scottish government sees offshore wind – and the hydrogen production which we hope will be enabled by offshore wind – as one of the most important economic and environmental opportunities we have,” said First Minister Nicola Sturgeon.

Vertex Hydrogen has awarded a project management services contract to Worley for its 350 MW low-carbon hydrogen production plant at Stanlow Manufacturing Complex in Ellesmere Port, England. “The 350 MW plant is the first in the UK to have completed front-end engineering and is expected to be one of the first large-scale and low-carbon hydrogen plants in the world,” wrote Worley.

Uzbekistan and Saudi Arabia’s ACWA Power have signed three energy agreements worth a total of US$12 billion (AU$17b). They plan to invest in green hydrogen in the Central Asian country together with Air Products, and they also signed a $10 billion (AU$14.4b) investment cooperation agreement to jointly develop gas-to-power, renewable energy, and green hydrogen projects in Uzbekistan over five years starting in 2023, said ACWA Power.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.