Allup Silica said a series of samples taken at the company’s Sparkler exploration project site in Western Australia’s (WA) southwest region had produced a consistent high-grade, low-iron silica sands product that exceeds the premium specifications required for solar PV applications.

Allup said bulk samples from four drill holes at the Sparkler project site, located about 200 kilometres from the port of Albany in WA’s southwest, had been tested at the Nagrom mineral processing facility in Perth. The results were reviewed by Battery Limits Metallurgical Consultants which published its findings in an independent metallurgical report.

“Some of the early indications are encouraging, and the company’s plan is to work towards achieving a commercial product within industry specifications of the sector we are striving for,” Allup said in a statement. “High-grade silica sand of this specification with a low-iron content will be in high demand for use in the manufacture of premium ultra-clear cover glass production, particularly for the burgeoning solar PV panel manufacturing industry.”

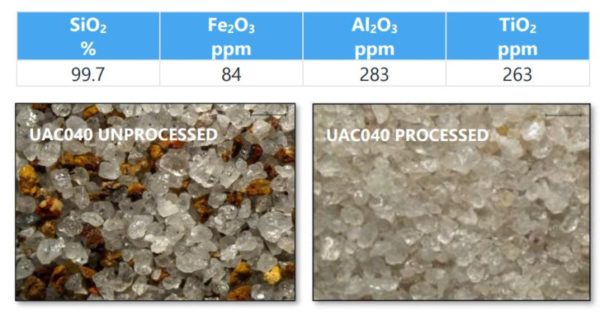

Image: Allup Silica

The announcement came after the Perth-based company adjusted its process circuit to improve overall silica recovery and decrease iron oxide impurities, which can lower the quality and value of silica sand materials.

The renewed process averaged 84 parts per million (ppm) iron oxide across all test results — well below the <100 ppm impurities benchmark for products hitting the solar panel market premium specification used for PV applications.

Combined with a silicon dioxide grade of 99.8%, Allup chair Andrew Haythorpe said the company is now primed to generate silica sands for PV applications — one of the company’s primary target markets.

“The results from the improvements we are making to the process circuit are very encouraging and indicate that we do have the right projects and the high-purity silica sands to start with,” he said.

“Being able to achieve the high-purity specs required for the manufacture of PV cells means we are on track, and we look forward to being able to supply samples to potential customers as we progress to development on our Sparkler project.”

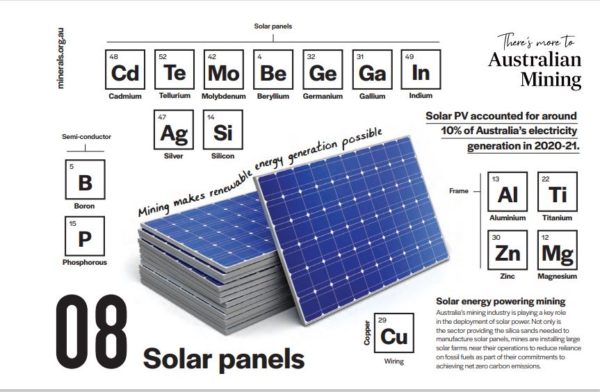

Image: Minerals Council of Australia

Silica sand is used in the production of optical fibre, ceramics and glassmaking, including the specialty glass required for solar PV panels and other high-tech product applications like tablet and mobile telephone glass.

Recent technology advances have also demonstrated that the addition of high-grade silica has the potential to replace graphite as the primary metal used in lithium-ion battery anodes, offering greater energy density and efficiency.

The Sparkler project is one of four silica sands projects Allup is exploring in WA. The company said its initial priority is to grow the existing 73 million tonne silica resource base at the Sparkler site towards a potential for commercialisation.

Allup plans to spend approximately two years building its resource base and conducting pre-feasibility study works with the aim of developing its assets into mining operations shortly thereafter.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.