Green Energy Systems, a 100% owned subsidiary of Sydney-based architectural and building systems company Systems Pty Ltd, has unveiled its prefabricated modular Solar Waves solution, a PV array in which panels come preassembled on an all-aluminium framing system.

Green Energy Systems founder and Chief Executive Officer Glenn said the design of the Solar Waves system “is revolutionary in that we have increased the strength, achieved a number of new outcomes has dramatically lowered the cost, by simplifying the framework to be a sliding assembly.”

“Our mission was to produce an entirely new system to deploy solar PV,” he said. “We had two aims: devise a method to get rid of most of the labour out of the system because that is expensive; and to reduce the system down to its bare bones as far as traditional methods of construction and deployment. And that included removing nuts, bolts, screws, rivets, clamps … all of that stuff is gone.”

Carless said the Solar Waves system has been designed to eliminate as much manpower from both the project site and factory as possible with the company having also engineered machinery that allows for the full automation of the in-factory assembly process.

“That’s where we have been able to make some very big inroads in the way of costs,” he said. “We have invented and patented what we believe to be the strongest and cheapest solar deployment system in the world. The complication is all gone. It’s very, very simple.”

Image: Green Energy Systems

The Solar Waves system comprises a series of shallow-pitched roof systems, each featuring two rows of five in-portrait modules mounted on aluminium frames with 11 units combined to form a 50 kW ‘mega wave’. The modules are assembled in a concertina shape at a 9-degree tilt and all are pre-wired as “plug and play”. When unfurled on-site the mega wave weighs 1,925 kilograms and measures 5.5 metres wide and 44 meters long. Two mega waves fit in a standard six-metre shipping container with 10 containers providing 1 MW capacity.

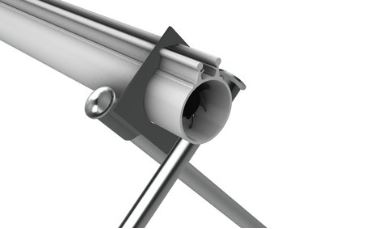

The Solar Waves system, fitted on a unique criss-cross footing which company data says can accommodate 400mm undulations from wave to wave in ground-mounted applications, has been tested and rated to survive category 5 cyclones.

Green Energy Systems claims the design, which it said is compatible with any of the major PV manufacturer’s panels, enables arrays to be positioned closely onsite “with about an 86% of total site coverage,” providing power to land area ratio of an estimated 205 W per square metre.

The solution is reminiscent of the Maverick technology offered by fellow Sydney company 5B but Carless said there are significant differences. Solar Waves uses no concrete pre-cast footings and, without changing the assembly, it can be ground mounted, floated on bodies of still water or installed as a waterproof roofing system over car parks or agrisolar applications.

Image: Green Energy Systems

“This is a very versatile system,” he said. “Without change we can supply waterproof roof systems and by adding recycled plastic floatation devices, we supply the system with sufficient buoyancy to float.”

“We also have a system for on-board individual battery system deployed at the same time as each Solar Wave within the large tubular frame.”

“Our system is 100% transportable, usable, reusable and at end of life 100% recyclable.”

The Solar Waves system is not yet available on the market but Green Energy Systems said it has spent the past 12 months prototyping, testing and certifying the technology and is now preparing to step up to full production.

Carless said the company has been working with engineering and design firm Arup to put the system into full production while aluminium extrusion company Capral has commenced production of the aluminium components.

Image: Green Energy Systems

“We have completed all preliminary tests and are now looking to scale up with a fully automated new factory just north of Sydney,” he said. “We presently have a small test factory in Warriewood for prototyping and testing but we’re about to invest in a much, much bigger factory of about 5,000 square metres, where we can supply vast quantities.”

“We already have strong interest in our systems but we are looking for further expressions of interest to help fund this endeavour.”

It is anticipated the first of the Solar Waves systems will be available for deployment by mid-2023.

“Probably within four to six months we’ll be up and running,” Carless said.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.