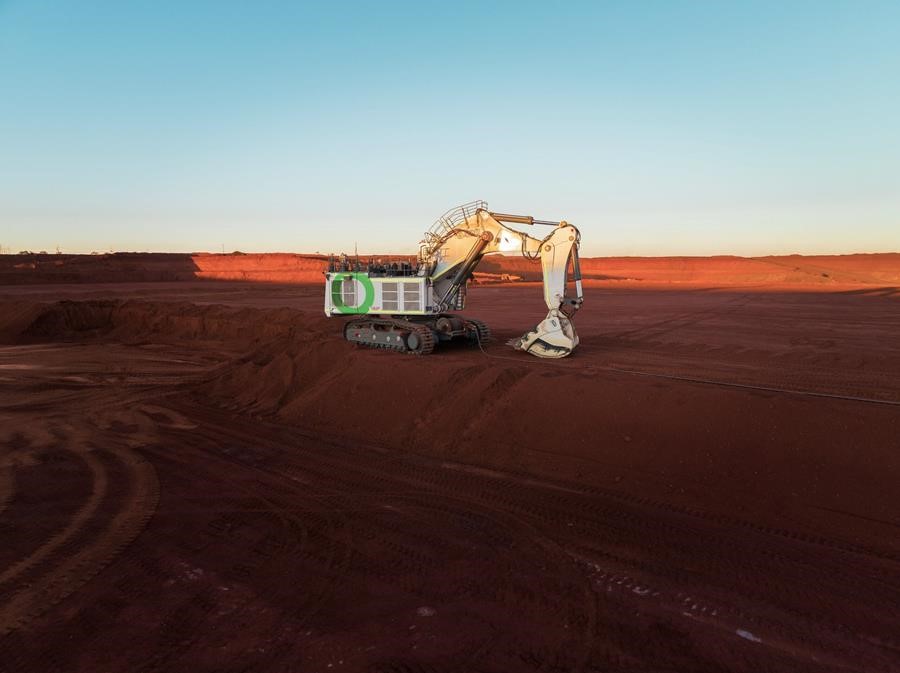

Mining and green energy major Fortescue has confirmed the first operational electric excavator in Australia has commenced operations at its Cloudbreak mine site in the Pilbara as part of the company’s decarbonisation strategy, which includes replacing its existing diesel-fuelled mining fleet with electrified and green hydrogen powered vehicles before 2030.

The excavator, which was converted from diesel and is now powered by a 6.6 kV substation and more than two kilometres of high-voltage trailing cable, is the first of an initial three R 9400 E electric excavators being delivered by German-Swiss equipment manufacturer Liebherr within the next 12 months.

“The commissioning of this fully electric excavator is a massive achievement by the team and is the first of its kind in Australia for the mining industry,” Fortescue Metals Chief Executive Officer Dino Otranto said.

“We’ve been fortunate enough to work with industry experts who have been using trailing cable for decades, and then repurpose this in our own operations as part of our decarbonisation journey.”

Otranto said the commissioning of the excavator is in line with Fortescue’s aim to eliminate emissions across its mining operations and for all electrified mining equipment to be fuelled by renewable energy., including at the Cloudbreak site which is partially powered by Alinta’s 60 MW Chichester Hub Solar Farm.

“Already, our Chichester operations which include Cloudbreak run partially off solar enabling this first excavator to be powered using renewable electricity,” he said. “Once we decarbonise our electricity grid, all these excavators will be operating on renewable electricity in the future.”

Fortescue is also trialling a battery-electric haul truck and a hydrogen fuel cell haul truck at its nearby Christmas Creek iron ore mining operation.

Image: Sandvik

Fellow miner AngloGold Ashanti is also pushing ahead with its plans to expand the lineup of zero emission mining equipment with the trial of a battery-electric underground mining truck at its Sunrise Dam gold mine site near Laverton, about 1,000 kilometres south of Fortescue’s Cloudbreak operation.

The TH665B truck, delivered by Swedish engineering company Sandvik, is powered by a 354 kWh lithium-iron phosphate battery with the electric driveline delivering 630 kW (858 hp) of power output.

Sandvik said as well as producing zero diesel emissions underground and generating 80% less heat, the TH665B is expected to be up to 25% faster on a 1:7 ramp than regular diesel trucks.

Andrew Dawson, business line manager for load and haul at Sandvik, said one of the standout features of the truck is its patented battery self-swapping system that enables quick and easy battery swap in a matter of minutes, and without any major infrastructure like overhead cranes or other heavy handling equipment.

“It is equipped with AutoSwap, our patented self-swapping system which makes the battery changing process extremely fast and easy, usually taking only three minutes,” he said.

Dawson said data gained from seeing the prototype working in Australian conditions will be invaluable as the company continues to develop its battery-electric range and the TH665B moves into commercial production phase.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

I would just like to clarify that this I isn’t the first solely elelectric powered excavator to operate in Australia.

Australian Blue Metal had a Ruston Bucyrus, I think a model RB110 operating at the Gosnels quarry ( south east of Perth) in the 1960s. I visited the quarry in the mid 1970s and it was still operating.

It’s great to see Fortescue’s continued leadership in electrification of mining, with both the Liebherr excavators and the Sandvik trucks.

I’m curious as to why there are not already electric excavators in Australia. Electric excavators are the norm in the Canadian oilsands and I had assumed that this was the case in the rest of the mining industry as well.