From pv magazine ISSUE 01/24

Data from more than 150 utility-scale solar projects in North America and Europe suggest that the incidence of cell microcracking is rising, reversing what had been an encouraging downward trend. Anecdotal evidence suggests the reversal is more common in North America than in Europe and that most defects occur during manufacturing.

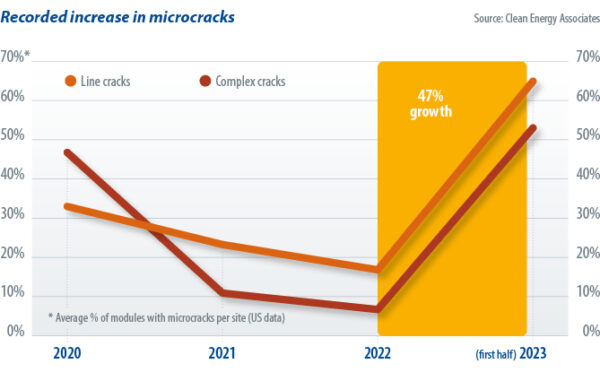

The 47% jump in microcracks observed in North America between early 2022 and mid-2023 coincided with ongoing shifts in the supply chain. Project owners have often had to find new sources for PV modules to meet import restrictions set by the US federal government. As a result, newer manufacturers are gaining market share from long-established market players but they may not have the same quality assurance steps in place.

Microcracks cannot be detected by visual inspection alone. With time, cracks can grow in much the same way that a chip in a car windshield can spread. Early detection is thus crucial, not only from a project performance standpoint but also as future warranty and insurance claims may be affected.

Awareness and timely action are the best tools for project owners and are more important than ever. Buyers should negotiate technical and quality requirements and inspection criteria before signing a purchase contract. They should also perform factory audits and inline production monitoring and pre-shipment sampling inspections at adequate frequencies and with tight acceptance limits, as per the ISO 2859 standard, with lab testing of production batches. Pre- and post-installation quality checks are just as vital since cell damage can occur anywhere from transport to handling to installation and operation.

Common EL defects

Over the last eight years, CEA has conducted electroluminescence (EL) testing on more than 300,000 modules across 150 projects in 16 countries. Our analysis found cell damage can occur across the entire module lifecycle, including manufacturing, shipping and storage, installation, and operation.

Many defects remain undetected unless EL testing is used. This detects defects in PV cells and panels that cannot be seen with the naked eye. The EL test process passes a current through a PV module in a dark environment to capture the emitted infrared light with specialised cameras.

Our analysis found four common EL defects: line cracks (found in 83% of sites in which modules were tested), soldering anomalies (78% of sites), complex cracks (76%), and edge ribbon cracks (29%).

Cell cracks can form during the manufacturing process and be present at the time modules leave a factory. Rough handling during transportation or installation can create new cracks or cause existing cracks to grow. Impacts to the module and severe weather events can also result in microcrack formation.

Line cracks are caused by relatively minor stress placed on a module or cell. These cracks lead to increased internal series resistance and, typically, minor power loss. Complex cracks are the intersection of multiple cracks to resemble an “X,” a “V,” or a tree branch, and can form from module damage or from growth of existing cracks. Complex cracks have an increased risk of resulting in large inactive areas that significantly reduce module performance and, in severe cases, panel hotspots.

Edge ribbon cracks form where the interconnect ribbon (or wire) crosses the edge of the cell. These are often the result of the cutting of the cells via laser ablation (which reduces the mechanical strength of the silicon wafer); or from excessive pressure from the tabbing-stringing process; or from the overlapping layers of material, in the case of tiling. More than 80% of sites that use half-cut cells were affected by edge ribbon cracks. They often start as a tiny line or V-crack but our findings suggest that these cracks are more likely to grow than other crack types and can become branch cracks, ultimately affecting both safety and performance.

Soldering anomalies occur when one or more stringing wires or ribbons that connect cells are not properly contacted during manufacturing. Module efficiency can be reduced and, in severe cases, hotspots can form and damage modules.

Tangible impacts

Microcracks can have tangible economic impacts for solar projects – they can exacerbate ongoing project under-performance issues, which obviously reduces revenue potential. They can also complicate future module warranty and insurance damage claims.

In the wake of recent supply chain disruption, anecdotal evidence exists of investors mandating both visual and EL tests for modules that have been in long-term storage or that have changed ownership since being imported.

In addition, insurers increasingly require post-installation inspections to set a benchmark against possible future damage claims.

While our analysis suggests that all types of microcracking are disturbingly common, potential problems can be controlled by third-party testing, from the factory through installation and operation. Long-established standards have proven to be effective at reducing the occurrence of microcracks. Adherence to those standards therefore remains critical as supply chains shift and new players are tested by markets.

Full analysis can be found in the CEA’s recent report, “Solar PV Module Quality Risks: A Summary of CEA’s Findings in the Field.”

About the author: Claire Kearns-McCoy is senior engineering manager at CEA. She has extensive experience with module field inspections and analysis of EL imaging tests. Claire previously spent three years at SunEdison, where she worked in solar module research and development, as well as manufacturing management.

About the author: Claire Kearns-McCoy is senior engineering manager at CEA. She has extensive experience with module field inspections and analysis of EL imaging tests. Claire previously spent three years at SunEdison, where she worked in solar module research and development, as well as manufacturing management.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.