Sydney-based scientists at Macquarie University (MQ) and the University of New South Wales (UNSW) have achieved breakthroughs to barriers preventing perovskite solar cells (PSCs) from achieving industrial adoption.

Supported by government agency Australia’s Economic Accelerator seed funding, the scientists developed green, sustainable perovskite solar cell technologies, by developing safe, eco-friendly solvents that can be used in large-scale manufacturing.

The industrially viable manufacturing for next-generation solar cells project focussed on toxic solvents used during PSC module fabrication, which pose risks to worker safety and the environment, restricting broader application.

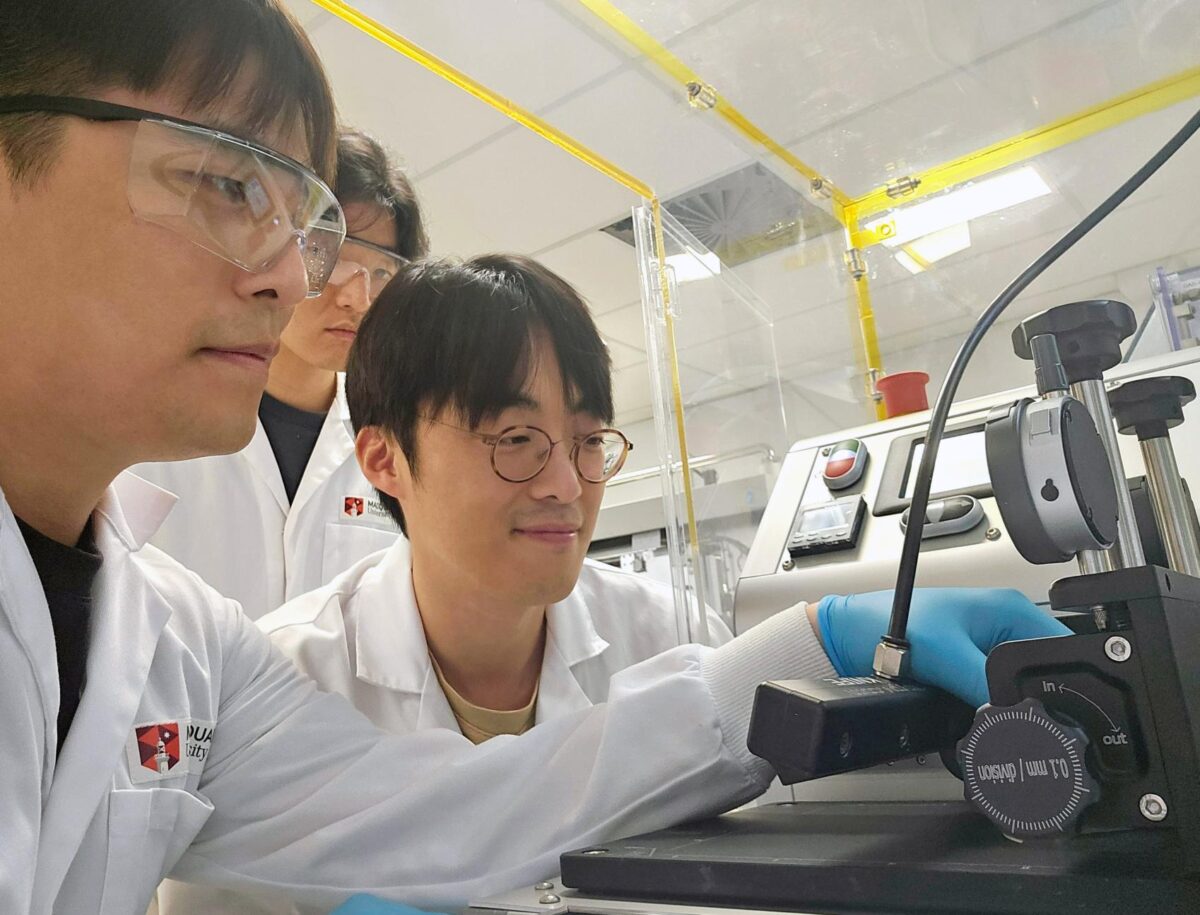

MQ professors Shujuan Huang and Dr Jincheol Kim in collaboration with Dr DJ Kim at UNSW developed new solvents, which have been found to help PVCs reach energy efficiencies of over 22%, making them safer for both the environment and workers.

The research team also took into account the cost and difficulty to scale current electron transport materials (ETMs), and manufacturing processes inhibiting commercial viability, and created affordable and scalable electron transport materials using graphene quantum dots (GQDs) made from natural fertilisers. The ETMs also achieved 22% efficiency and improved the stability of the solar cells.

Professor Huang said the team successfully synthesised nitrogen-doped graphene quantum dots, which have greatly improved the efficiency and stability of our perovskite solar cells.

“This breakthrough has opened new avenues for commercial applications,” Huang said.

Another development has been the creation of an optimised method called slot-die coating, which is a way to apply materials evenly and resulted in solar cell modules with efficiencies of over 16%, which they say is one of the best performances globally.

“Our project is strategically positioned to attract further investment by leveraging its key outcomes,” Huang said.

“The two potential patents stemming from this work—on green perovskite ink and slot-die coating for green PSC manufacturing—will be pivotal in securing industry partnerships and additional funding.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.