As 2025 topples some proponents of renewable hydrogen, the question of its long term viability is one Siemens Energy Australia Managing Director Samuel Morillon told pv magazine can only be answered with time.

Heading up the Australian arm of German-headquartered energy giant Siemens, Morillon said departures will inevitably happen at such an early stage of renewable hydrogen’s development here.

“When you look at history, the industrialisation of Europe took more than 100 years. The construction of what we see in terms of grid assets in Australia took more than 60 years, and we started basically working on the hydrogen topic only a couple of years ago,” Morillon said.

“Definitely we have questions when we see that projects are not able to reach a financial closing, but we need to have a more realistic view, and we need to think more long term.”

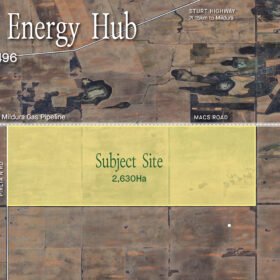

Image: Siemens Energy Australia

Morillon added that considering the development stages of Australia’s main partners in the hydrogen story, such as Korea, Japan and Europe, helps to understand how hydrogen will play a key role in the future.

Right now, Siemens Energy electrolyser technology is currently in play at the $14.5 million (USD 9.2 million) Australian Gas Infrastructure Group’s (AGIGs) Hydrogen Park South Australia (Hyp SA).

The facility blends up to 10% renewable hydrogen with an existing gas supply for 3,700 connections in a nearby neighbourhood, and further afield via tube trailers.

Located in the Tonsley Innovation Precinct, 11 kilometres south of Adelaide’s CBD, Hyp SA uses a 1.25 MW Siemens Energy proton exchange membrane (PEM) electrolyser.

“More than the equipment itself, which is really demonstrating that our technology is reliable and affordable, for us it’s a demo case for what we plan to do in the future,” Morillon said.

“The transition to hydrogen will take time, we know this, but we are demonstrating with this that it works and that we are in basically to support customers if they have the willingness to proceed.”

Morillon said a more realistic view of hydrogen in Australia is in the context of what he calls the Pacific Belt, which links the production of hydrogen here to what is going on in Korea and Japan, and, to the broader pace of transition to hydrogen energy.

“We expect over the next few decades, hydrogen will be more and more present, and, in this context, the different states of Australia are definitely key because Australia has the land, the sun and the wind available to produce a highly efficient and affordable hydrogen, for the domestic market and export as well,” Morillon said.

In the meantime, he said Australia’s transition is still reliant on extracting energy sources like coal.

“Right now, when we look at the picture of the quantity of renewables we are producing in the country, it’s close to double what we had 10 years ago,” Morillon said.

“In the meantime, we need to recognise and accept that Australia still relies on coal, and close to 50% of the energy production basically comes out of the ground, and coal is very cheap, so when we are speaking about energy transition, the question of price comes to the table, and the acceptancy of the energy transition by local communities is absolutely key.”

While Siemens Energy technology is embedded in many renewable energy infrastructure projects in Australia and New Zealand, supporting traditional oil and gas energy companies to decarbonise and cope with variable energy, is an area where the company is heavily engaged.

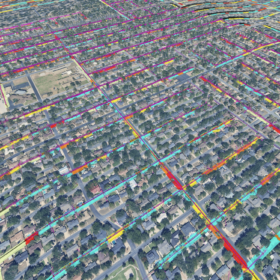

“Australia’s energy transition will be properly achieved if the grid – which is made up of different and independent grids – is resilient and connected as well,” Morillon said.

“So, we support number of numerous projects, which are enforcing the grid stability and its expansion.”

Siemens Energy’s first project in Australia to convert an operating gas turbine unit to a Hybrid rotating grid stabiliser (RGS) is at the RATCH-Australia Townsville Power Station in Queensland which utilises a Siemens Energy SGT5-2000E gas turbine to provide grid stability services.

Found to fall short of the Australian Energy Market Operator’s (AEMOs) requirement for a minimum fault level in response to increased renewable energy entering the grid, the gas turbine was retrofitted with a synchro-self-shifting (SSS) clutch to the shaft to provide instantaneous switch power generation to synchronous condenser mode.

When in synchronous condenser (SynCon) mode, the Hybrid RGS unit can provide rotating inertia and short-circuit power without the need to produce power and is calculated to provide a short-circuit contribution of approximately 350 to 400 MVA.

“It’s basically a machine which is able to take the best of the two worlds. We are using a gas turbine to stabilise the grid, and this is not to oppose oil and gas to renewables but it’s about using the best of two worlds, because we are working in gigawatts, so it’s a question of scale and our ability to provide for very large investments with a positive impact for customers and communities,” Morillon said.

On utility-scale batteries, which are also stabilising the grid Morillon said the key issue is reliability.

“We need to provide electricity, which is affordable, reliable, and with technology that is accepted by communities. When we speak about price, it’s comparable. The big topic is the reliability. When you are speaking about batteries you need to have in mind that the efficiency of these batteries will decrease during time, quite significantly,” Morillon said.

“So, when you are doing your business case, basically the duration of the business needs to be double checked to be sure that it fits with your customer expectations.”

Morillon added that the land available for a battery project needs to be considered and the length of time it can support the grid.

“Knowing that basically right now the biggest battery we have in Australia is able to support the grid for maybe one or two hours maximum, so when you compare a couple of hours to the need for delivering power continuously even in a long period of blackout, the battery works extremely well, but has limitations,” Morillon said.

“When it comes to our SynCon and other areas of equipment that I was speaking about, you also have some limitations, definitely linked to the site, to the technology, which needs to be deployed, and so what we need to do again is to be pragmatic.”

Morillon added that checking what fits best to the project must remains affordable and that the power to be produced will be reliable, and acceptable by communities.

Updated 30 April 2025

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.