A research team led by TU Delft in the Netherlands simulated moisture ingress in PV modules to better understand degradation caused by humidity. They analysed the effect of encapsulant and backsheet material choices and climate conditions.

“What is novel in our work is that we have reported the relative concentration of moisture content rather than the actual concentration, as the literature suggests this is a more relevant metric for assessing degradation in PV modules,” Youri Blom, corresponding author of the research, told pv magazine.

Indeed, one of the key findings described in “Modelling moisture ingress in PV modules with different encapsulant and backsheet materials,” published by Renewable Energy, is that using relative moisture concentration (RMC) as a stress factor in degradation models is a “better indicator” than the more commonly used effective relative humidity (RH).

To analyse moisture ingress inside a PV module the team simulated devices over a 20-year period made with three different encapsulants and four different backsheet materials as well as modules located in eight cities across four climate zones.

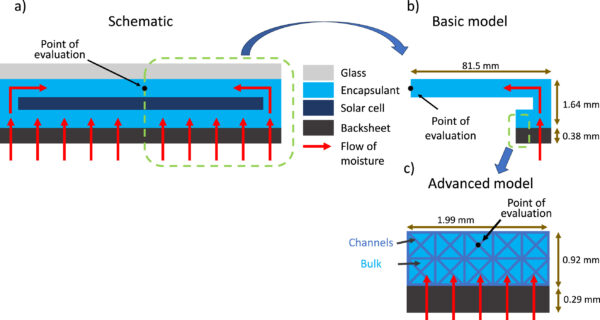

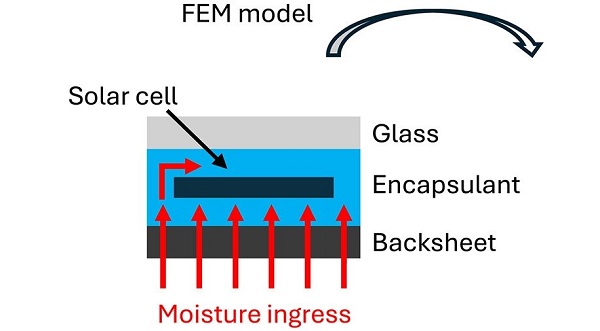

They used a finite element method (FEM) model built in COMSOL Multiphysics. It incorporated Fick’s second law of diffusion and Henry’s law for the backsheet and air interface, according to the research.

The Peck model, which is an acceleration model for temperature and humidity evaluation of moisture-induced IC failure within epoxy over-molded components, was used to calculate the normalised power through the module’s lifetime.

Image: TU Delft, Renewable Energy, Creative Commons License CC BY 4.0

For encapsulants, the team selected ethylene-vinyl acetate (EVA), thermoplastic polyolefin (TPO) and polydimethylsiloxane (PDMS). For the backsheets, polyethylene terephthalate (PET), tedlar-PET-tedlar (TPT), tedlar-PET- SiOx (TPSiOx), and polyamide (PA) were selected. Their properties were obtained from published sources.

The reference PV module used EVA as the encapsulant and PET as the backsheet.

Eight cities were grouped into four climate zones: tropical represented by Manaus, Brazil, and Jakarta, Indonesia; temperate represented by Los Angeles, U.S., and Freiburg, Germany; arid represented by Dubai, UAE, and Almeria, Spain; and continental represented by Portland, U.S., and Oslo, Norway.

The scientists validated the model with indoor experiments and outdoor simulations from literature.

“In our research, we found that the climate in which a PV module is installed has a much higher impact on the moisture ingress than the choice of materials for the encapsulant of the backsheet,” said Blom.

“This suggests that it can be beneficial to have different PV module designs designed for specific climates, rather than one global solution design.”

The researchers subsequently developed a “simple analytical equation that can be used to predict the moisture ingress” without relying on time-consuming and computationally intense simulations.

“This equation only contains four unknown parameters that can be obtained from the climate conditions of the installed location,” explained Blom.

The less computationally intense analytical model used empirical parameters derived from the FEM simulations and it achieved an accuracy deviation of less than 0.05.

The researchers concluded that it can effectively predict moisture ingress in new locations without resorting to computationally intensive FEM simulations.

“It was surprising to see that all characteristics that are also used in the simple analytical model can accurately be fitted with a linear trend with respect to a specific stress factor.

This was a key step in the development of the analytical model, as it allows us to predict these characteristics for new locations without re-doing the simulation,” said Blom, noting that his team is planning to conduct more simulations to analyse lifetime simulations, other degradation mechanisms and their effects on PV modules.

Researchers from Belgium’s IMEC, Hasselt University and EnergyVille contributed to the research.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.