Researchers from the Australian National University (ANU) have investigated the techno-economic aspects of integrating PV and batteries in heavy industry through energy simulations and new high-resolution energy modelling framework that incorporates lifecycle degradation and production intermittency.

“Our study addresses a core question: can PV and batteries reliably provide 24/7 electricity for energy-intensive industries such as steel, aluminum, and cement?” the research’s corresponding author, Bin Lu, told pv magazine. “Using an integrated modelling framework, we compare three strategies: technology cost reductions, grid interaction, and industrial load flexibility. This comparative assessment offers new insights into how each strategy shapes the cost-effectiveness of PV-based electricity supply for heavy industry.”

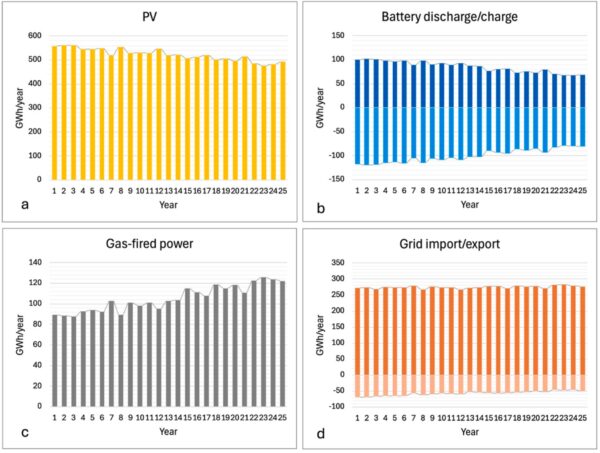

The key feature of the new methodology is its ability to co-optimise electricity generation, storage, and utilisation at an hourly temporal resolution over an economic lifespan of 25 years. Furthermore, PV intermittency is captured across multiple timescales, addressing the operational needs of heavy industries under diverse weather conditions, while the decline in electricity generation and storage capacities over time is also reflected in it. Computational constraint is addressed by using a non-linear net-load method within the energy balance modelling framework.

In the modelling, a 24/7 continuous industrial operation is assumed to be powered by onsite PV and batteries, with gas turbines as backup.

A heavy industrial operation in Western Australia is used as a case study, where a 100 MW continuous industrial load is modelled as the baseline scenario. Both PV and batteries are modular and can be readily scaled to suit the size of any industrial operation, depending on the scenario.

The team investigated three strategies. In the technology cost reduction strategy, different scenarios of falling prices of PV batteries were examined; in the grid integration strategy, the industrial facility was allowed to import and export electricity from and to the grid; while in industrial load flexibility cases, the facility could shift production of some of the industrial processes to sunny hours. The PV efficiency was held constant at 21% for the Li-ion battery storage at 85% and at 50% for the gas turbine.

The degradation rates for the PV unit were 0.6% per year and 1.8% for storage, while the discount rate was 6% over a 25-year lifespan. Operation and maintenance costs for PV were assumed at $12 (USD 7.9) / kW/year, and 1% of the capital cost/year for the batteries. Capital costs for PV ranged across the different scenarios from $300/kW to $1,500/kW, and the battery ranged from $100/kW + $100/kWh to $500/kW + $500/kWh.

“The most surprising result is that even if PV and battery costs fall by 80%, the electricity cost for heavy industry decreases by only about 40%. The reason is energy spillage. When solar generation exceeds what the industry can consume or store, the excess energy must be curtailed,” Lu said. “Our study highlights effective pathways to overcome this constraint. Smart grid interaction and flexible industrial operation substantially improve solar energy utilisation, reducing costs more effectively than technology cost reductions alone. These strategies allow industries to capture more value from solar generation and achieve deeper decarbonization at lower cost.”

The research team also found that grid interaction reduces reliance on gas-fired backup power and could lower electricity costs by up to 42% while achieving 100% renewable energy integration. Load flexibility achieved by adapting industrial operations to renewable energy variability could reduce electricity costs by up to 80% while enabling 100% renewable energy integration.

“Our next step is to work with steel, aluminum, and cement companies to translate these findings into industrial applications,” Lu said. “Future demonstration projects will help optimise flexible operational strategies under practical industrial conditions and inform large-scale implementation across industry.”

The research work was presented in “Decarbonising heavy industry operations with low-cost onsite photovoltaics and battery storage,” published in Solar Energy.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.