The Australian Renewable Energy Agency (ARENA) has committed $25.3 million (USD 16.5 million) to Sydney-based solar technology company SunDrive in support of taking its copper solar cell breakthrough to a market-ready technology.

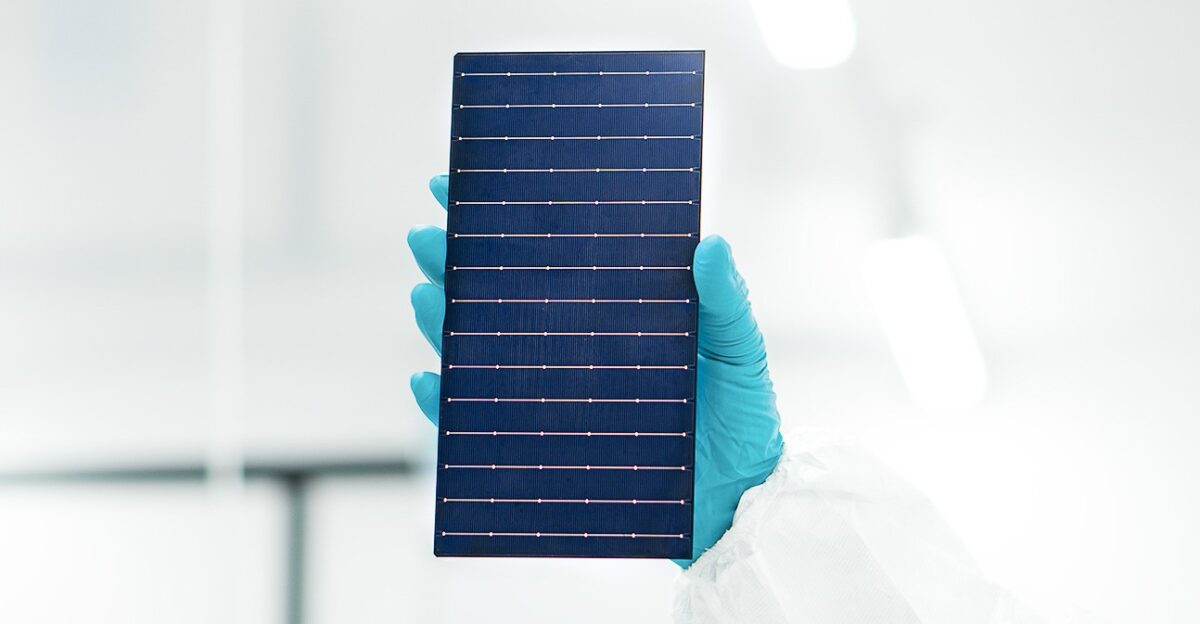

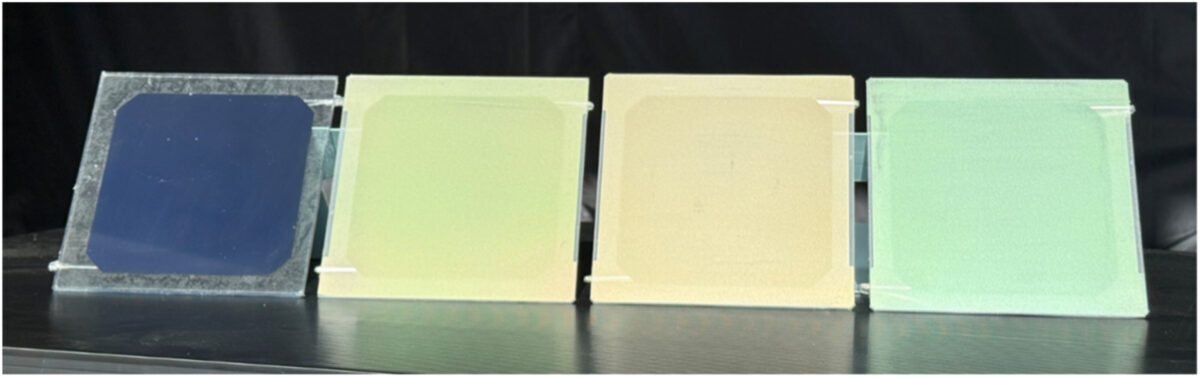

SunDrive’s copper-based process replaces silver in solar cells, aiming to cut costs and improve efficiency and supports ARENA’s ultra-low cost solar goal.

Funded through ARENA’s Advancing Renewables Program (ARP), the investment will support SunDrive to scale and commercialise its copper metallisation solar cell technology research and development facility in South Sydney to a 300 MW commercial-scale production tool, in collaboration with leading solar cell manufacturing companys Maxwell Technologies and Jiangsu Vistar Equipment Technology.

SunDrive Chief Executive Officer Natalie Malligan said the funding marks a major step taking the leap from world-leading research to commercial reality.

“It’s a strong validation of our strategy to develop world-class solar innovation here in Australia and partner with the best in the industry to industrialise it,” Malligan said.

“It shows how Australian innovation can compete globally, and how with the right support, we can take homegrown technology to the world.”

SunDrive Co-founder Vince Allen said with Maxwell world records in cell efficiency have already been broken.

“This next phase builds on that success and represents the culmination of our work to translate our copper plating technology into the industrial tools that will define the next generation of solar cell technology,” Allen said.

“With silver prices nearly tripling in three years and solar now using a third of global industrial silver, the industry urgently needs a silver-free alternative. With ARENA’s support and our partners’ expertise, this project intends to deliver a scalable mass-production solution.”

ARENA has previously funded SunDrive with $14 million to demonstrate the copper metallisation technology.

ARENA Chief Executive Officer Darren Miller said by tackling one of the biggest cost items in solar cell manufacturing, SunDrive is demonstrating how Australian research can drive next-generation solar innovation.

“Not only is copper more abundant and cheaper than silver, but SunDrive’s unique manufacturing process also results in higher cell and module efficiencies which could have huge benefits for global decarbonisation efforts,” Miller said.

“We’re providing a further $25 million in funding to help scale up SunDrive’s technology which could significantly help push the boundaries of efficiency and affordability and unlock the potential of ultra low-cost solar.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

When will the demonstration unit be completed?