5B to ramp up expansion after $30 million capital raise

Prefabricated solar array manufacturer 5B has completed a $30 million Series B capital raise with their existing shareholders to help fund continued development of the company’s flagship modular Maverick solar array and accelerate the progress of the company’s pipeline of multi megawatt projects.

India installed 456 MW of rooftop solar in Q1

India’s rooftop solar installations increased by 34% year on year in the January-March period, despite a 17% increase in system costs.

BYD launches new C&I battery

Chinese battery manufacturer BYD has launched an expanded portfolio of energy storage systems designed for the commercial and industrial solar markets. At The smarter E in Munich last month the company also provided a sneak peak at a new high-voltage storage system expected to be launched later this year.

Trina Solar’s pathway to TOPCon

Trina Solar will eventually start selling TOPCon and heterojunction products, even though it built its first large-scale TOPCon project four years ago. The company says it is now making progress on TOPCon module production, despite supply chain issues.

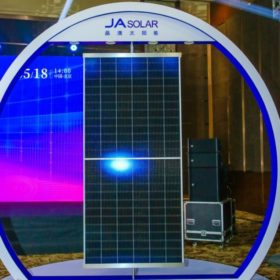

JA Solar introduces n-type solar panel with 22.4% efficiency

JA Solar said the smallest solar panel in its new n-type product line has a power output of 435 W and a power conversion efficiency of 22.3%. The largest module in the series has an efficiency rating of 22.4% and 625 W of nominal power. Their temperature coefficient is -0.30% per degree Celsius.

Test production starts at SolarEdge’s 2 GWh Korean battery cell fab

The inverter and battery manufacturer says its new Sella 2 factory will produce cells for its residential solar-plus-battery products as well as for other applications.

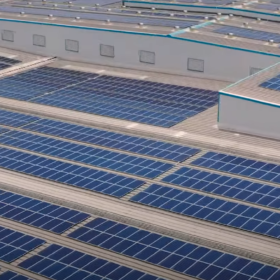

Canadian Solar plans to ramp up production capacity

Having warned of in-house solar wafer and cell capacity as recently as the third quarter of 2021, the company has announced it will be adding even more production lines this year.

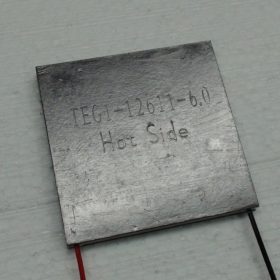

Upcycling silicon waste from end-of-life solar panels into thermoelectrics

Researchers in Singapore have developed a new technique in which polycrystalline silicon is pulverised into powder and pelletised into ingots. The process relies on spark plasma sintering to dope the silicon with germanium and phosphorus.

Sungrow’s new battery to be deployed in 16 mid-scale Victorian solar farms from Lavo

Chinese inverter brand Sungrow has signed a 79 MW inverter and 176 MWh battery energy storage contract with Sydney-based hydrogen battery company Lavo. The contract will see Sungrow add its storage solution to 16 mid-scale solar farms in Victoria.

China’s cumulative PV capacity tops 322 GW

In other news, Zhonghuan Semiconductor announced it will begin selling 210 mm n-type wafers and the local government in Zhejiang Province said it wants to deploy another 12.4 GW of new PV by 2024.