Saturday read: Promising alternatives to lithium-ion

Lithium-ion batteries are a fantastic crutch for the renewable energy transition. It’s not all roses, though: Short duration limits, and potentially dangerous thermal runaway in rare circumstances, means the hunt continues for alternative electrochemical batteries. However, alternatives will largely complement lithium-ion batteries, rather than supersede them. Blake Matich looks at promising options to keep an eye on.

Module price hike impacting middle-sized PV projects in South Korea

The continuous rise in solar panel prices may affect PV projects of up to 1 MW tendered by the Korea Energy Agency and the domestic solar module industry may not be able to provide the necessary production capacity to respond to the recent supply bottleneck.

WA company finds foothold in Germany in transformation to ‘preeminent’ global battery recycler

In the coming weeks, Western Australian mining-cum-materials recovery company Neometals will begin testing at its newly commissioned battery recycling demonstration plant in Hichenbach, Germany, the product of a joint venture with SMS Group. The Primobius facility, as it’s named, has already garnered considerable attention and is a finalist in 2022’s prestigious German Sustainability Award. “We want Primobius to be the preeminent recycler in the world,” the company’s managing director, Chris Reed, told pv magazine Australia.

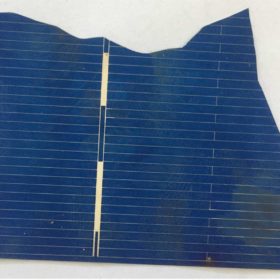

New tech to recover pure silicon from end-of-life solar cells

An Indian research group has used three different chemicals instead of commonly used hydrofluoric acid to separate silicon from the cell. The technique is claimed to be able to deliver recycled silicon with a purity of up to 99.9984%.

Sunman unveils 430 W glass free solar module

The new product has a power conversion efficiency of up to 19.3% and a weight of 11.2 kg. The module is produced with glass fibre reinforced plastic, which the manufacturer says reduces light reflection and opens up new assembly options.

Sunday read: What’s next for polysilicon?

The past 12 months have proved profitable for polysilicon manufacturers, as selling prices have soared to levels not seen since 2011. However, with major new capacity expansions on the horizon from most of the leading manufacturers, and new players planning to enter the scene, the market balance looks set to shift. Exawatt’s Alex Barrows rounds up where the industry stands and what might happen next.

Saturday read: ‘India presents a big market opportunity for us’

Sujoy Ghosh, First Solar’s vice president for India and the Asia-Pacific region, speaks to pv magazine India’s Uma Gupta about the company’s plans to set up a 3.3 GW module fab in India to service the local market.

Module and shipping cost inflation could cost the world 50 GW of solar next year

The input costs of the two biggest contributors to solar plant development expense have gone through the roof since the world began to come out of Covid-19 lockdowns, to leave project developers with some difficult choices.

Innovative Australian battery materials projects gain momentum at home and abroad

A number of Australian battery material recovery projects got off the ground this week, including the completion of Western Australian outfit Neometal’s battery recycling demonstration plant, a Queensland-Japanese joint venture studying the extraction of cobalt from copper tailings as well as the funding of Sydney-based startup Novalith.

Hydrogen fuel cells and equipment to be manufactured in Victoria under new H2X deal

Hydrogen vehicle maker H2X has today announced a deal with Gippsland Circular Economy Precinct which will see the pair manufacture a range of hydrogen-focussed products in Victoria’s Gippsland region. The move comes less than a week after Pure Hydrogen bought a significant stake in H2X Global.