Trina Solar doubles down on PV 5.0

Trina Solar’s two new bifacial solar modules are touted as a “game changer,” not only for utility-scale projects, but for commercial and industrial developments as well. PV innovation continues to reduce costs and improve performance, but Australia’s outdated infrastructure is doing its best to slow the transition down.

Short-term symptoms

The COVID-19 outbreak has disrupted the global PV supply chain. China, the largest manufacturing hub for solar products, has postponed factory openings in many regions, as it has been hit by logistical hiccups, staff shortages, and delivery delays. Manufacturers in some Chinese provinces are running under capacity, while those overseas are facing the same situation.

BNEF lowers 2020 global PV outlook due to coronavirus concerns

Many solar factories in China are starting to resume production, suggesting that concerns about supplies of PV components could soon begin to ease. Nevertheless, the temporary standstill will have an impact on the global solar market, as the implementation of some projects will probably be postponed until next year.

How the new generation of 500 W panels will shape the solar industry

With three models of 500 W solar panels officially unveiled, here’s a look at what it means for the future of project development and the solar industry at large.

AE Solar enters Australian market, introducing new module features

German-headquartered module manufacturer AE Solar is looking to enter the Australian market in 2020. It has begun accrediting its module range with the Clean Energy Council and believes its Supreme module series, which are shade and hot spot resistant, will attract installers.

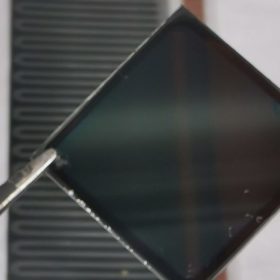

International consortium claims 25% efficiency for flexible CIGS solar cell

Researchers led by Belgian institute imec claim to have achieved the result with a 1cm² flexible thin-film cell intended for building-integrated PV application. The result tops the 24.6% efficiency the consortium announced in September 2018. The cell’s developers are now aiming for 30%.

RACV partners with Enphase to boost its rooftop PV offering

The deal will see the U.S. technology company supply its smart microinverters as part of an RACV initiative to enhance its current residential and commercial solar offerings.

First Solar announces surprise fourth-quarter loss, considers sale of development business

‘First Solar, at its core, is a technology and module manufacturing company,’ said Mark Widmar, chief executive of the U.S. company.

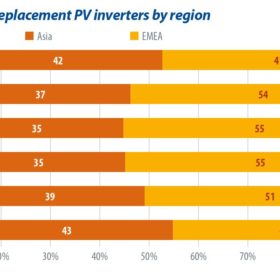

Out with old inverters, in with the new

Global demand for replacement inverters will likely grow by almost 40% to reach 8.7 GW in 2020, as a large and expanding installed base of aging solar PV installations drives deployment, writes Miguel De Jesus of IHS Markit.

QUT: A titanium solar cell with 24% efficiency

The Australian research team which developed the device said the higher efficiency was achieved through a nanowire design which eliminates the interface inside the titanium dioxide band.