China plans new polysilicon production, 100 GW of solar for desert areas

China’s president has detailed plans to accelerate the planning and construction of large-scale wind and PV projects in desert areas, while Wuxi Shanghai announced new granular silicon and nano-silicon production capacity expansions.

Reliance Industries acquires 100% stake in REC Group, plans new manufacturing bases

India headquartered multinational Reliance Industries, through its subsidiary Reliance New Energy Solar Limited, yesterday announced the acquisition of Norway headquartered module manufacturer REC Group. The move comes as Reliance pushes forward with its US$10 billion plan to move in on the renewable energy industry, having also this week announced acquisition of a 40% share in EPC provider Sterling & Wilson.

Electro-thermal storage system for commercial applications launched

Developed by Swedish manufacturer Azelio, the system stores renewable energy in recycled aluminium and has an electrical and thermal energy output, with a total efficiency of 90 %. One unit’s storage capacity reaches 165 kWh of electrical output and on top of that thermal energy between 55-65 degrees Celsius. Its modular configuration allows the deployment of projects with a capacity of up to 100 MW.

Saturday read: Chinese U-turn on stranded Australian coal could aid solar imports

China’s coal crunch looks set to see the nation turn to the Australian coal it has kept stranded via its year-long unofficial import ban. The news isn’t great for CO2 emissions, but could ease the significant impacts being felt by the Chinese solar industry.

New ‘matrix’ layout for shingled solar cells

German equipment supplier M10 and research institute Fraunhofer ISE will unveil a new prototype stringer for shingled module layouts at the Intersolar Europe trade show later this week. Employing an offset layout for the shingles, the approach promises a relative efficiency gain of up to 6%, compared to a conventional half-cell module.

Fortescue eyes 1 GW solar PV module manufacturing plant

Fortescue Future Industries has revealed plans to develop a 1 GW solar PV module manufacturing plant in Australia after confirming it had acquired a 60% stake in Netherlands-based renewable energy specialists High yield Energy Technologies Group.

Vanadium redox flow batteries with purported LCOS of $0.10/kWh

Singapore-based VFlowTech has secured funds to scale up manufacturing of its vanadium redox flow batteries. The company currently offers three modular products that can be scaled to multi-megawatt-hour systems.

Vietnamese manufacturer unveils PV module for agrivoltaics

Vietnamese manufacturer Irex has announced a new glass-glass solar panel with a power output of 265 W and a power conversion efficiency of 18.1%.

Solar tile with 14.2% efficiency from Denmark

Dansk Solenergi ApS has developed a 13.6 kg tile that can be used for both new buildings and building renovation. The device is currently being produced in Denmark, where the company operates a 40 MW line.

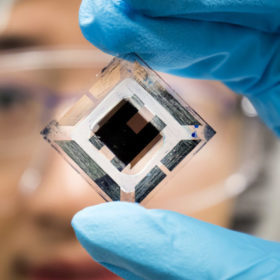

New discovery could make organic PV competitive with crystalline silicon

A group of international researchers has observed how non-radiative charge recombination occurs in organic PV and claims to have identified a potential solution that could bring this solar tech closer to crystalline silicon in terms of power conversion efficiency.