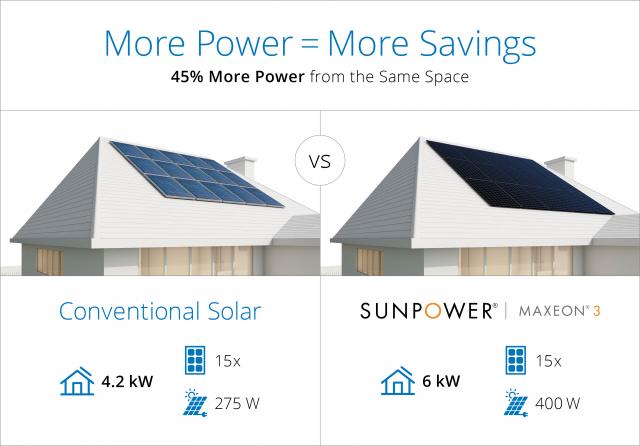

SunPower’s latest generation of PV modules continue to push efficiency and power output. The new Maxeon 3, introduced this month in Australia and Europe, will see power output increased on the previous Maxeon modules by 30-40 W, with the most powerful of the Maxeon 3 crossing the 400 W mark.

“SunPower is introducing the world’s first 400-watt residential solar panels as most in the industry are just crossing the 300-watt threshold for home solar,” said Jeff Waters, CEO of the SunPower Technologies business unit in a statement.

U.S. installers will be the first to get their hands on SunPower’s A-Series modules, which deploy 65% larger cells and comes in at 400W and 415 W. The A-Series comes with a factory-integrated microinverter, making it “ideal for use” with the integrated Equinox rooftop kit, the company says – with the whole system covered by the single warranty.

Both the Maxeon and A-Series modules utilize SunPower’s Interdigitated Back Contact (IBC) solar cells – the highest-efficiency solar products available on the mass market. The cells in the A-Series, however, are significantly larger – delivering higher power output and potentially lower manufacturing costs to SunPower.

IBC cells have layers of copper and aluminium that extract electricity off the back of the cell and no grid lines or busbars on the front. And like SunPower’s X-Series and E-Series, the A-Series panels offer very high efficiencies, from 21.5-22.3% at the module level.

That is still higher than any mass-market rival, including SunPower’s biggest high efficiency competitor LG Solar – even when accounting for LG’s new NeON R product, which, like SunPower’s, uses IBC cells.

War on costs

But not only is NGT based on much larger, 6-inch wafers – a development that is likely the result of ongoing advances in monocrystalline ingot casting in China – but SunPower says it uses a cheaper manufacturing process. The company has consistently refused to reveal how much NGT reduces costs but CEO Tom Werner has said, through manufacturing efficiencies and higher throughput, NGT will be on par with mono-PERC technology.

A SunPower cell.

Image: Paul Sakuma Photography/PaulSakuma.com

That’s the right benchmark to be aiming for. Driven by the rise of massive mono ingot and wafer factories owned by Longi and Zhonghuan and the spread of PERC cell technology, mono-PERC products are coming to dominate utility-scale as well as rooftop markets, and both Jinko and Hanwha’s new U.S. factories are producing mono-PERC output.

Shipment plans

SunPower says it expects to ship up to 100 MW of A-Series modules this year, and to reach 250 MW of annual manufacturing capacity by the year’s end. By the time it completely converts its Fab 3 in Malaysia to NGT, it will have 800 MW of capacity, some of it enabled by higher throughput in the NGT process.

It remains to be seen if that will enable SunPower to turn a profit. The company has taken all the right steps, both in reducing costs and shifting focus to rooftop markets where the advantages of its high-efficiency products reap the greatest reward – and has had to pay for those investments. Now we will see if all of that work pays off in dollars and cents.

The SunPower A-Series, on the right, is 10% longer than the X-Series.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

I am kindly asking for a spec sheet on your new 400W solar panels