Against the backdrop of an international commitment to fast-track the development of hydrogen worldwide, the Queensland University of Technology (QUT) is at the forefront of Australia’s push to promote hydrogen fuel. After it played a key role in Australia’s first green hydrogen shipment to Japan, QUT is now readying to host Queensland’s first hydrogen refuelling station.

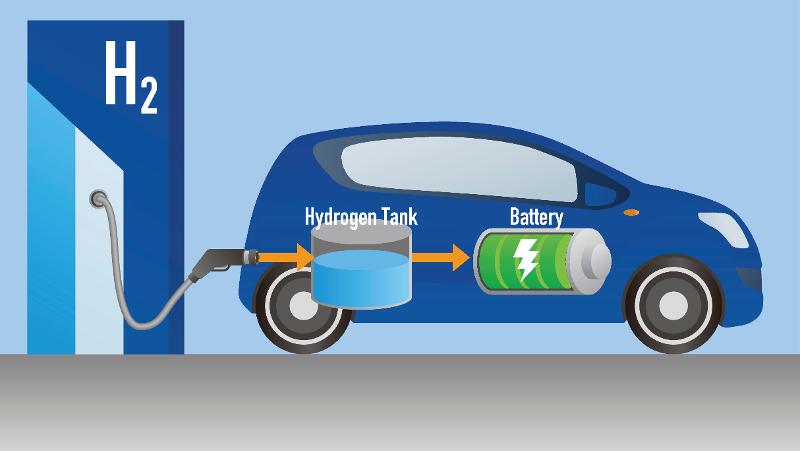

The state-of-the-art station at the Kelvin Grove campus will be able to refuel hydrogen fuel cell electric vehicles in under three minutes. It will be used by hydrogen cars added to the Queensland Government’s vehicle fleet as part of the $19 million Queensland Hydrogen Industry Strategy 2019-2024.

Gas and engineering company BOC has been tapped to supply the renewable hydrogen to fuel the vehicles and install a hydrogen refuelling station at QUT, Brisbane. The company unveiled the $3.1 million end-to-end renewable hydrogen supply initiative in late August, describing it as “Queensland’s first renewable hydrogen project”.

BOC plans to install a 220 kW electrolyser supplied by ITM Power and 100 kW solar array to produce renewable hydrogen through electrolysis at its Bulwer Island site. The electrolyser will have capacity to produce up to 2,400 kilograms of renewable hydrogen per month to power hydrogen fuel cell electric vehicles and supply the company’s industrial customers. Backed by $950,000 in funding from the Australian Renewable Energy Agency (ARENA), the project is expected to be completed by mid-2020.

“We are looking forward to including Hyundai and Toyota vehicles in the trial as they are at the forefront of fuel cell technology,” Minister for Housing and Public Works Mick de Brenni said earlier.

H2 export

While working with BOC to deliver the refuelling station, QUT is also leading a $7.5 million research project to establish a pilot plant producing green hydrogen fuel at the Redlands Research Facility. Earlier this year, QUT partnered with Japanese petroleum conglomerate JXTG to produce and export green hydrogen to Japan.

Transporting hydrogen is associated with a host of challenges in terms of cost, energy efficiency, purity challenges, and minimising leakage. But, in Queensland’s landmark trial, hydrogen was extracted from water in the form of an oil-like substance suitable for transportation using conventional road tankers, pipelines and super tankers.

A team of researchers from JXTG produced green hydrogen by adding water and acid to a chemical called toluene using solar power as the energy source in the electrochemical conversion process. “The toluene is converted to a substance called methyl cyclohexane (MCH), which is an energy efficient and safe method for transporting hydrogen,” said Professor Ian Mackinnon, from QUT’s Institute for Future Environments. “In this form, hydrogen can be shipped using conventional road and pipeline infrastructure. Once it has arrived at its destination, the renewable hydrogen is extracted from the MCH and the toluene can be re-used in the transportation cycle.”

The hydrogen that was shipped by JXTG to Japan was produced at QUT’s solar cell facility, which features both CPV and PV arrays, located at the government-owned Redlands Research Facility, south of Brisbane. The JXTG trial is separate project to but aligned with a $7.5 million research project to build a hydrogen production pilot plant at the Redlands facility, which will use locally produced solar energy to extract hydrogen from treated non-drinking water, such as seawater. The pilot plant has been underpinned by funding of $3.35 million from ARENA and $250,000 from the Queensland government.

Finally, QUT Professor Ian Mackinnon was recently appointed as the strategic hydrogen advisor to the Queensland Government. “The University’s commitment to hydrogen development in Australia facilitated through partnerships and strong working relationships with industry is a key step toward a workforce adequately skilled for expansion of the clean energy sector,” he said.

In one of its earlier breakthroughs, QUT researchers have demonstrated the efficiency of a cobalt-nickel-gold system for electrochemical production of hydrogen, which could replace expensive, currently used materials, such as iridium oxide, ruthenium oxide and platinum.

The process uses “two earth-abundant cheaper alternatives, cobalt and nickel oxide, with only a fraction of gold nanoparticles” – which boost efficiency of the catalyst – “to create a stable, bi-functional catalyst” that splits water and produces hydrogen without emissions.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.