From the April edition of pv magazine

Currently there are challenges, but thankfully there are also ways to minimize and eliminate the impact of LeTID. It will be the work of manufacturers, suppliers and consumers to ensure that we take the right path forward.

As solar cell technologies continue to evolve and modules become more efficient, it’s inevitable that new degradation and failure modes will also be discovered. Just as solutions to boron-oxygen light-induced degradation (BOLID) were being developed, a new and more severe long-term degradation mechanism was observed. Termed light- and elevated temperature-induced degradation (LeTID) by Hanwha Q Cells in 2015, the effect can cause more than 10% power loss over several years of module operation in the field. Further, performance may not ever recover over the typically expected 25-year lifetime of a module.

This level of degradation is disastrous for manufacturers’ warranties and for system owners, leading to reduced energy yield and an increased levelized cost of energy (LCOE). This is bad news for both consumers and producers, which is why understanding and solving LeTID is a key focus of our work at UNSW Sydney.

While the exact defect causing the degradation is still up for debate, there is now general research consensus that hydrogen plays an important role in causing LeTID, something which complicates the push for increased hydrogen in cells to neutralize other defects. First identified in p-type multi-Si PERC cells, LeTID also affects p-type mono-Si cells, often to a lesser extent. It has also been identified in float zoned, n-type and Ga-doped Si to varying degrees, making LeTID a universal defect that could potentially affect all silicon solar modules. Understanding the impacts of this degradation is key to informed decision making for consumers and manufacturers.

Quantifying impacts

To quantify the impact of long-term degradation and recovery as encountered in the field, an accelerated lab test is required. However, acceleration can alter rates of degradation and recovery separately, as reservoirs or ‘buckets’ of hydrogen in a device are released under different conditions, causing LeTID. This can change the time scales and maximum power loss measured and differs from cell to cell or module to module. These complexities make true LCOE and long-term performance predictions nearly impossible to accurately assess.

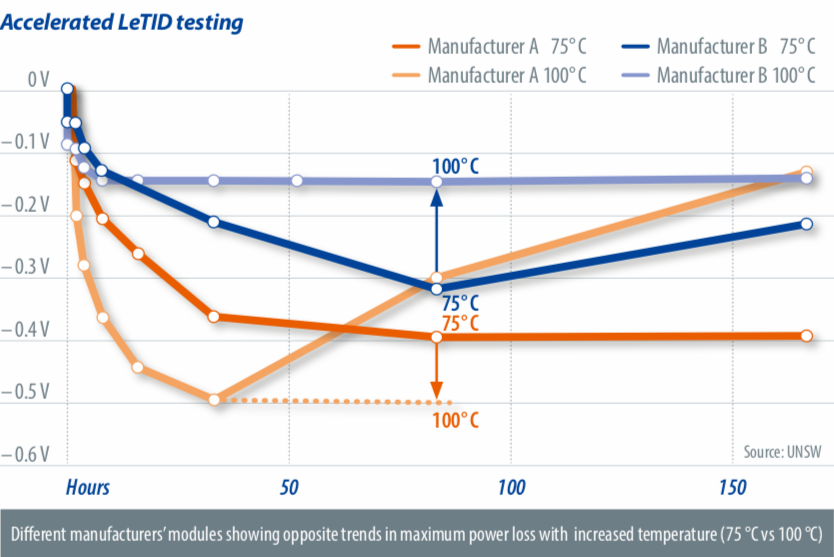

This has been shown previously in research presented by Fokhul and others at the 2019 EU PVSEC conference. Comparing mono and multi modules in-lab, the maximum multi power-loss was unchanged with increased acceleration, but the mono modules showed either reduced power loss or none – though missing the fact that the modules would likely degrade in field conditions. We have seen this effect even when comparing the same underlying structure (p-type multi PERC) from a range of manufacturers, where increased testing temperature causes some modules to have a larger power loss, where others are reduced (see contrasting behaviours from two different manufacturers in the chart to the right).

Standards and certification

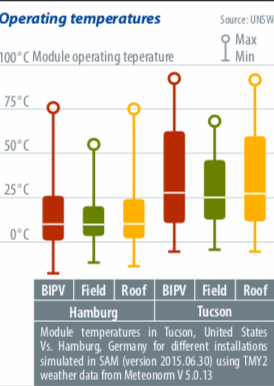

IEC 61215-2 draft standards, (hopefully to be confirmed this month, if not postponed due to Covid-19) use 75 °C and current injection to ~maximum power point conditions, measured roughly weekly. After 800 hours (~five weeks), the maximum power loss the module would experience in the field is unlikely to be seen. This poses several questions: How accurately does this reflect different installations? Would modules in the field degrade more or less significantly? And how quickly would they recover?

This is where things get much more complex. Modules in the field aren’t subjected to just one set of lab-controlled conditions; they vary widely depending on the installation location, climate and installation type. Field modules with airflow, for example, are unlikely to go above 70 °C, even in relatively hot climates. However, for BIPV or roof-mounted installations without airflow, modules could reach temperatures approaching 100 °C (see chart to the upper right).

This becomes more of an issue when the degradation and recovery rates are both independent and competing. The hydrogen buckets and LeTID behaviour are highly variable depending on the device voltage, silicon wafer, doping, dielectric layers (hydrogen sources), thermal processing, and testing (or operation) conditions.

The huge variability in the patterns and extent of LeTID – even within the same structure – can come from even very slight differences in the thermal processes. While this makes testing and identifying more challenging, it also creates an opportunity to use thermal processes to manipulate the hydrogen and LeTID to reduce the degradation extent, or even eliminate degradation completely. We are already beginning to see this introduced commercially, as TÜV Rheinland has awarded LeTID stability certificates to some manufacturers.

Unless the specific defect is identified and eliminated, there will be an ongoing need to modify solutions as cell technologies and processes evolve. Best applied at cell level, module manufacturers should ensure that cells used in their modules are acceptably LeTID-stable.

While lab testing can’t reproduce the exact, complex conditions as in the field, determining LeTID sensitivity is nonetheless important. The forthcoming IEC 61215-2 will provide some reassurance to consumers by identifying those modules with a reduced sensitivity to LeTID. However, a module which just scrapes through the certification process can lose up to 5% of power and still be degrading the equivalent of more than 1% per year (the test halts when successive measurements lose less than 1%.) System owners wanting increased stability and assurance should request to see the actual testing data to decide if the power loss is acceptable to them.

Recognising the importance of improved testing and being able to identify new degradation and failure modes in the continual evolution and improvement of photovoltaics, UNSW is currently ramping up its module research with a custom-built 2 m x 1.3 m AAA test surface Climate Chamber Solar Simulator from Eternal Sun, due for delivery in its labs later this year.

About the authors

Alison Ciesla, researcher, UNSW

Alison Ciesla is a Scientia Research Fellow at UNSW Sydney. Through collaboration with industry, she specializes in understanding defects and hydrogen in commercial solar cells, especially regarding the degradation and reliability of PV modules.

Brett Hallam, associate professor, UNSW

Brett Hallam is an associate professor at UNSW Sydney, specialising in carrier-induced degradation of silicon solar cells and cell efficiency improvements, as well as commercialization of various technologies to industry.

The views and opinions expressed in this article are the author’s own, and do not necessarily reflect those held by pv magazine.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

This LID, LeTID, or BOLID degradation is a known variable in solar PV installations. At the utility solar PV level several plants are being designed with the so called clipping, where the D.C. solar PV buss is 1.5 times the D.C. to the actual A.C. inverted output of the site. So, a 1.5 to 1 takes into account a 10% degradation over an extended period of time. With solar PV panel pricing coming down and new technology being brought out almost every year, prices for panels will not drop precipitously as they have in the past, but an honest $0.20 to $0.25/watt may well be possible in the next few years. The industry hasn’t witnessed the roll out of bifacial panels and their price point on the remaining single sided panels still being manufactured today. The bottom line is in the future, one can overdesign their system and take into account long range degradation, panel ‘dusting’, LID, and (still) design a 30 year system with solid output and use for 30 years plus. Now all one needs is the battery technology with cheap cost, long charge/discharge, relatively compact and pretty much temperature stable. Being able to build a residential energy storage system, with energy storage in the 100 to 150kWh range without having complex BMS, cooling systems, onboard fire suppression systems, would bring the costs down to affordable for homeowners and small business owners. So, will 24M and Kyocera be the ‘ones’ to bring out this very technology? Will companies like Sustainable Energy Inc. become players in the residential storage sector? Bring it on, I’m saving up for it right now.